At Fiver Star New Materials, we are dedicated to revolutionizing the construction materials industry by delivering innovative and high-performance products. Today, we will delve into the profound significance of collaboration between aerated concrete block manufacturers and aluminum paste producers like ourselves.

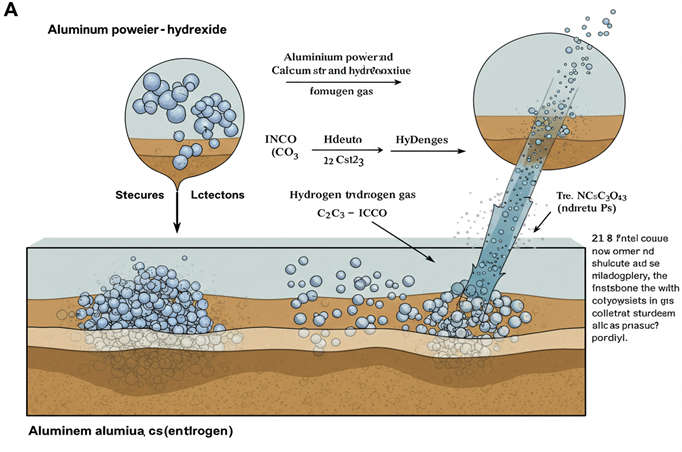

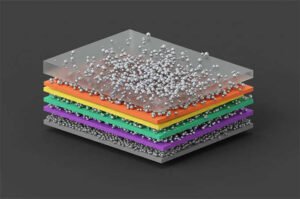

In the rapidly evolving world of construction, aerated concrete blocks have become a popular choice due to their excellent thermal insulation properties, lightweight nature, and high-strength characteristics. Aluminum paste plays a pivotal role in the production of these blocks as a crucial foaming agent. Recognizing this, we have been committed to enhancing the compatibility of our aluminum paste with the production processes of aerated concrete blocks.

By joining forces, we can drive technological innovation, optimize product performance, reduce costs, and expand market opportunities, thereby creating a mutually beneficial situation for both parties. Our goal is to provide our partners with the highest quality aluminum paste tailored to meet their specific needs and to work closely with them to advance the development of the aerated concrete block industry. Through our joint efforts, we aim to build a more sustainable and competitive future for the construction materials sector.

At Fiver Star New Materials, we believe in forging strong partnerships. Autoclaved Aerated Concrete (AAC) block manufacturers gain significant advantages by collaborating with us, a leading aluminum paste manufacturer in China. This collaboration drives mutual success, from technological advancements to sustainable practices.

Elevating Technology and Product Quality Through Partnership

Tailored Aluminum Powder Characteristics for Superior Performance

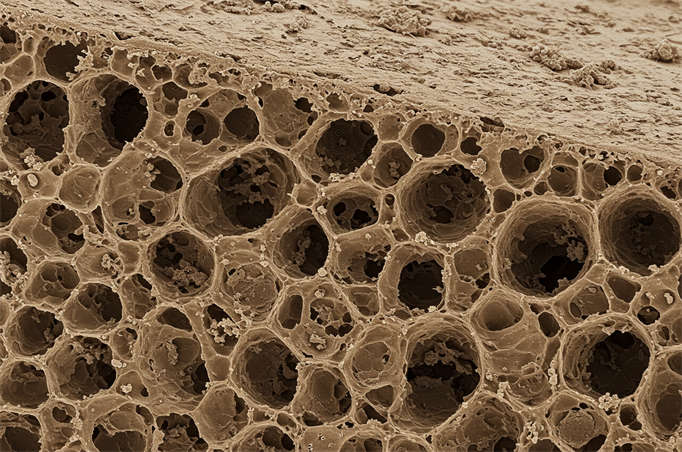

We understand that the aluminum powder in our aluminum paste acts as the crucial aerating agent in AAC block production. Through close collaboration, we ensure the purity, particle size distribution, and activity of our aluminum powder precisely match your AAC production process and formulation. High-purity aluminum powder consistently generates uniform and appropriately sized hydrogen, resulting in a more structurally organized porous network within the blocks. This directly enhances your product’s strength and thermal insulation properties.

Harmonized Research and Development Initiatives

Fiver Star New Materials actively engages in joint research and development with our partners. We explore innovative aluminum-based aerating agents and modified aluminum paste to meet the evolving demands for high-performance AAC blocks. For instance, we develop aluminum paste products that are suitable for a wide range of raw materials and process conditions, ultimately enhancing your production efficiency and product quality.

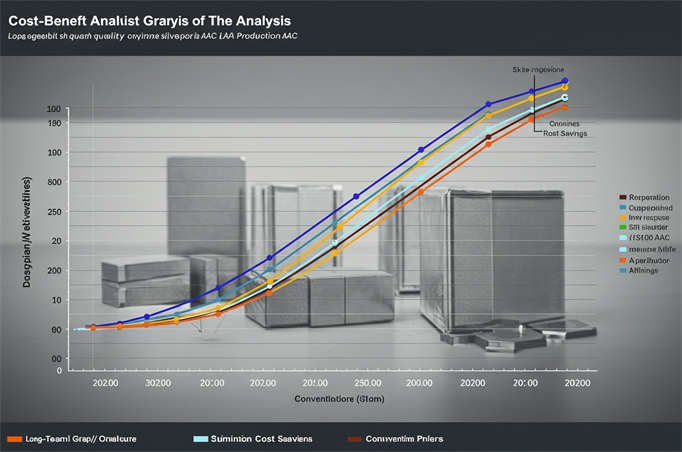

Optimizing Costs and Strengthening Your Supply Chain

Stable Supply and Robust Cost Control

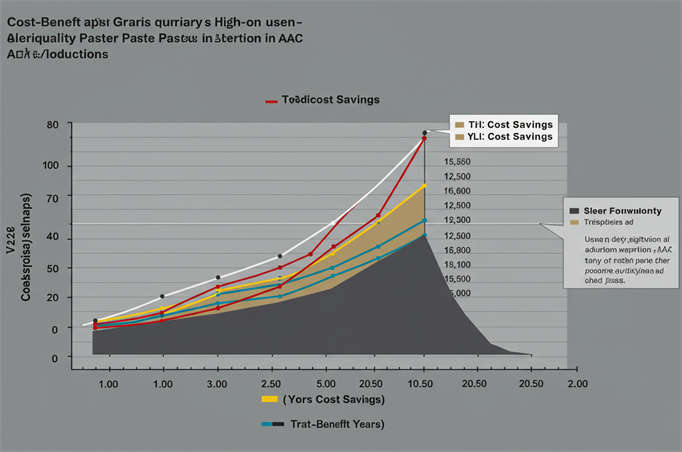

Partnering with Fiver Star New Materials guarantees a stable supply of aluminum powder, preventing production disruptions caused by raw material shortages. Our large-scale procurement capabilities and collaborative approach enable us to significantly reduce your purchasing costs, thereby strengthening your competitive edge. In return, your consistent orders will allow us, as an aluminum paste manufacturer, to optimize our production planning and achieve cost savings.

Proactive Quality Management and Shared Risk Mitigation

Our collaboration extends to vigilant oversight of aluminum powder quality throughout the production process. We proactively address any quality issues, minimizing potential production losses for AAC block manufacturers. When market conditions or raw material supplies become challenging, we work together to mitigate risks. This includes co-developing alternative materials or optimizing processes to minimize cost impacts.

Expanding Market Reach and Industry Influence

Broadening Market Collaboration

We integrate our market resources and client networks across the building materials and chemical sectors. This enables us to jointly promote products, capture market opportunities, and expand our market share. AAC block manufacturers leverage our reputation as a trusted aluminum paste manufacturer to enter new market segments, and we benefit similarly from your established presence.

Shaping Industry Standards and Gaining Influence

As key players in our respective industries, we actively participate in setting industry standards for AAC blocks and related raw materials. This standard-setting not only regulates market order but also enhances market recognition and competitiveness. Together, we gain greater industry influence, driving the future direction of the sector.

Driving Environmental Protection and Sustainable Development

Advancing Eco-Friendly Production

Fiver Star New Materials employs environmentally friendly production processes and materials, reducing harmful emissions. We provide AAC block manufacturers with energy-efficient aluminum powder, ensuring compliance with environmental regulations and jointly tackling ecological challenges.

Pioneering Resource Recycling

Our collaboration examines the utilization of by-products, including waste from aluminum paste production, in AAC block manufacturing. This promotes waste recycling, reduces costs, minimizes pollution, and significantly improves resource utilization efficiency, yielding substantial environmental benefits. Ultimately, this enhances our collective capabilities for sustainable development.

Optimizing DEG Aluminum Paste for AAC Production

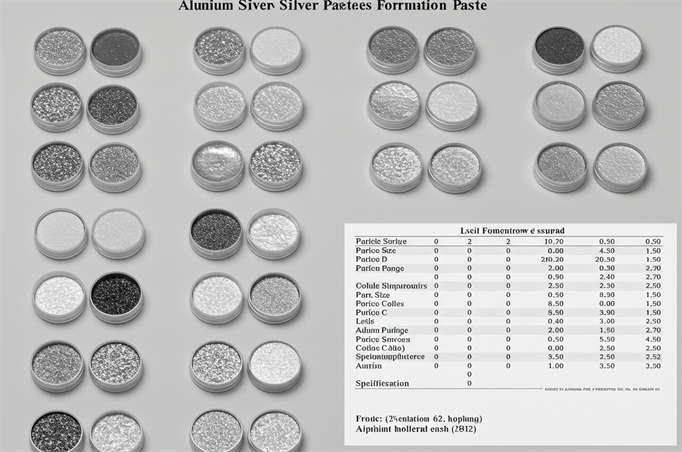

How Fiver Star New Materials Fine-Tunes DEG Aluminum Paste Characteristics

DEG (diethylene glycol) aluminum paste serves as a crucial additive in building materials, playing a vital role in the production of AAC blocks. At Fiver Star New Materials, we precisely adjust the characteristics of our aluminum paste to suit your AAC production needs ideally. We achieve this through:

Production Process Adjustments:

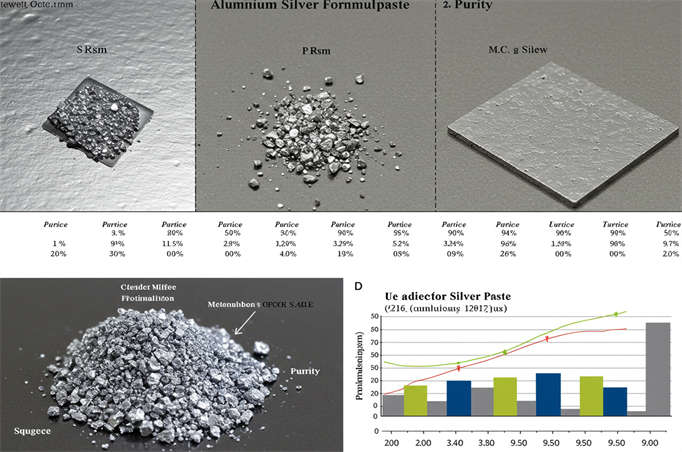

- Raw Material Selection and Treatment: We meticulously select high-purity, uniformly sized aluminum powder, ensuring consistent reactivity and bubble quality. For instance, we use high-purity aluminum ingots and then process them through melting, atomization, and sieving to obtain the ideal particle size. We also apply appropriate surface treatments to the aluminum powder, such as adding stearic acid, to prevent oxidation during the ball milling process and enhance chemical stability.

- Controlling the Milling Process: By adjusting the ball milling time and the amount of grinding aids, we precisely control the particle size and morphology of the aluminum powder. Generally, slightly longer milling times and increased usage of grinding aids result in finer and more consistent aluminum powder particle sizes, thereby enhancing activity and gas generation characteristics. For example, we maintain the d97 particle size of our aluminum powder between 280-630 μm to achieve optimal gas evolution.

- Selecting Solvents and Additives: Our careful selection of suitable solvents and additives is crucial to the performance of aluminum paste. DEG is a commonly used solvent due to its good solubility and compatibility with aluminum powder. We also incorporate appropriate thickeners and dispersants to enhance the dispersion stability of our aluminum paste, preventing aluminum powder agglomeration and sedimentation.

Performance Testing and Evaluation:

- Gas Generation Testing: We utilize gas generation testers to measure the gas volume and rate of our aluminum paste over a set period. This ensures our product meets your AAC block production requirements for gas output and speed. Typically, we aim for a gas volume of at least 100 ml per gram of aluminum paste, with a moderate gas generation rate, to ensure uniform bubble formation and stable existence.

- Assessing Slurry Stability: We meticulously observe our aluminum slurry for stratification and sedimentation during storage and use, rigorously evaluating its stability to ensure optimal performance. We use centrifuges to process the aluminum slurry and measure parameters, such as the sedimentation ratio, to determine its stability. Additionally, we check the viscosity and density of the aluminum slurry, ensuring excellent flowability and workability during your production.

- Compatibility Testing: We conduct thorough compatibility tests by mixing our aluminum slurry with other raw materials, such as cement, lime, and fly ash. We observe for flocculation or stratification, which would indicate poor compatibility. If necessary, we adjust our aluminum paste formulation or the processing of raw materials. For example, adding appropriate water-reducing agents or other admixtures can improve the compatibility of our aluminum slurry with cement and other materials.

Production Process Control:

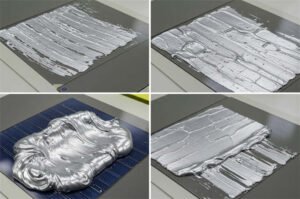

- Batching and Mixing: In AAC block production, we emphasize strictly adhering to the formulation ratios when adding our aluminum paste, ensuring thorough and uniform mixing with other raw materials. We recommend using forced mixers to disperse the aluminum paste, promoting uniform bubble generation.

- Pouring and Aeration: Controlling pouring speed, slurry temperature, and humidity during pouring is crucial for successful gas generation from our aluminum paste within the slurry. Pouring too quickly or at too high a slurry temperature can lead to rapid gas evolution and excessive bubbling, which may cause slurry collapse. Conversely, pouring too slowly or at too low a slurry temperature might result in insufficient gas, negatively impacting the block’s pore structure and strength.

- Curing and Cutting: During the block curing process, strict control over curing temperature, humidity, and duration ensures ample gas reaction from our aluminum paste and optimal block strength development. During cutting, careful consideration of cutting methods and timing prevents damage to the block’s internal structure.

Post-Processing and Optimization:

- Quality Inspection: We conduct comprehensive quality inspections on the manufactured AAC blocks, evaluating appearance, dimensional deviation, compressive strength, and dry shrinkage. Based on test data, we analyze the impact of our aluminum paste characteristics on block quality, allowing us to adjust our aluminum paste production process and formulation promptly.

- Performance Optimization: We continuously refine our aluminum paste performance to meet diverse production needs and raw material characteristics. This includes developing new aluminum paste formulations to enhance gas generation characteristics, stability, and compatibility, as well as adopting advanced production technologies and equipment to improve production efficiency and quality consistency.

Mastering Aluminum Paste Blending Techniques

Fiver Star New Materials’ Approach to Consistent Aluminum Paste Blends

Achieving a consistent and stable aluminum paste blend is paramount. Here’s how we ensure excellence in our blending process:

Preparation Before Mixing:

- Equipment Inspection and Cleaning: We meticulously inspect our mixing equipment to ensure it is free from debris damage and operates properly. We also maintain a pristine working environment to prevent contaminants from compromising the quality of our aluminum slurry.

- Raw Material Pre-treatment: We conduct specific pre-treatments on raw materials, such as aluminum powder, including screening to remove lumps and impurities, thereby ensuring a uniform particle size. We precisely weigh and pre-mix other ingredients to guarantee accurate preparation.

Key Considerations During the Mixing Process:

- Equipment Selection and Parameter Control: We select the appropriate mixing equipment, such as three-dimensional mixers, V-mixers, or double-cone rotary mixers, based on production requirements and the characteristics of the aluminum paste. We carefully set mixing time and speed. Generally, we avoid excessively long mixing times and high speeds to prevent damage to aluminum powder and the generation of static electricity.

- Mixing Sequence and Addition Method: We first introduce some solvent or raw materials into the mixer, then gradually add aluminum powder and other additives. This prevents aluminum powder agglomeration, facilitating better dispersion and mixing of all components. We maintain continuous mixing during the addition process to ensure even contact among all components.

- Preventing Agglomeration and Dust Dispersion: Aluminum powder tends to agglomerate, which can lead to dust dispersion. During the mixing process, we add appropriate dispersants or surfactants to aid in aluminum powder dispersion. We also carefully control mixing speed and equipment pressure to prevent dust dispersion, minimize material loss and air pollution, and reduce the risk of fire.

- Multiple Mixing Steps and Intermediate Checks: For high-demand aluminum slurries, we employ a multi-stage mixing approach. This involves an initial mix, followed by partial removal for inspection. Based on the inspection results, we adjust the formulation or mixing process as needed. We repeat this process as necessary until we achieve the desired uniformity in mixing.

Post-Mixing Solutions:

- Homogeneity Testing: After mixing, we conduct thorough homogeneity tests on our aluminum slurry, utilizing chemical analysis and physical testing methods to ensure uniform distribution of aluminum powder and other substances within the slurry.

- Slurry Storage and Application: We store our blended aluminum paste properly, protecting it from reaction with atmospheric moisture and oxygen. Before use, we re-mix the aluminum paste to ensure its uniformity. We also strictly control the dosage and application rate of the aluminum slurry based on your production requirements.

The collaboration between aerated concrete block manufacturers and aluminum paste manufacturers is crucial in today’s construction industry. At Fiver Star New Materials, we take pride in our ability to supply high-quality aluminum paste that meets the specific requirements of aerated concrete block production.

Our commitment to technological innovation, product optimization, and customer-oriented service has enabled us to build strong partnerships with numerous aerated concrete block manufacturers. Through our joint efforts, we have achieved significant progress in improving product quality, reducing costs, and expanding market share. Looking ahead, we will continue to explore new possibilities and push the boundaries of what is achievable.

With our expertise and dedication, we can help our partners achieve greater success and make a positive impact on the construction materials industry. For more Information about our aluminum paste products and collaboration opportunities, please visit our website or contact us directly. Let us work together to shape a brighter future for the industry.