Welcome to Five Star New Materials’ blog, your trusted resource for premium aluminum paste solutions in the paints manufacturing industry. In this comprehensive guide, we delve into the intricacies of aluminum paste, examining its unique properties and how it can enhance your paint formulations to new heights.

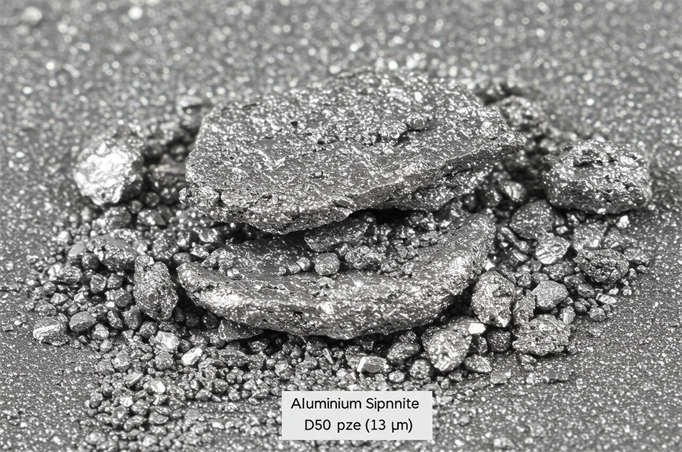

Aluminum paste, a cornerstone in the paints manufacturing sector, is a versatile material composed of flake-shaped aluminum pigments blended with solvents and additives. Its properties, such as particle size, morphology, and chemical stability, play a pivotal role in determining the performance and aesthetic appeal of paints. For instance, our ZYD513 aluminum silver paste, with a median particle size (D50) of 13 μm, exemplifies how specific formulations can cater to specialized applications, such as agricultural film color masterbatches.

At Five Star New Materials, we understand that the success of your paints manufacturing process hinges on the quality and reliability of your raw materials. Our aluminum paste is meticulously crafted to meet the highest standards of performance, ensuring that your paints not only look exceptional but also provide robust protection and durability. Whether you’re producing automotive paints, architectural coatings, or industrial finishes, our aluminum paste can be tailored to suit your unique requirements.

In this blog, we’ll take you through the various aspects of aluminum paste, from its physical and chemical attributes to its diverse applications in the paints manufacturing landscape. We’ll also shed light on the importance of choosing the right aluminum paste supplier—one that can provide consistent quality, innovative solutions, and unwavering support. Join us as we uncover how aluminum paste can transform your paint products and drive your business forward in a competitive market.

At Five Star New Materials, we pride ourselves on producing high-quality aluminum paste that revolutionizes the paints manufacturing industry. Our advanced aluminum paste offerings empower coatings with stunning aesthetics, superior protection, and enhanced performance.

Key Characteristics of Our Aluminum Paste

We carefully formulate our aluminum paste to deliver exceptional results in diverse applications:

Form and Particle Size

Our aluminum paste is a thick substance composed of fine aluminum pigment, additives, and solvents. For instance, our ZYD513 aluminum silver paste, used in agricultural film masterbatches, has a median particle size (D50) of 13μm. Particle size has a significant influence on paint performance and application, and different applications typically require specific particle size requirements for aluminum paste.

Non-Volatile Content

Our ZYD513 aluminum silver paste boasts a 70% non-volatile content. This means that 70% of the aluminum paste components remain in the paint during production, actively contributing to the paint’s properties and film formation. This significantly impacts the paint’s additivity and film-forming characteristics.

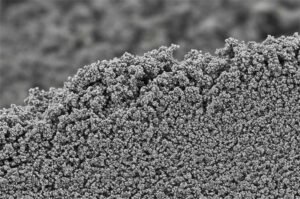

Flake Structure

The physical structure of our aluminum pigment is flake-shaped, which helps the aluminum pigment create unique optical effects in paint, such as glitter, hiding, and reflection. However, this structure also necessitates careful handling; you should avoid rapid shearing and repeated granulation during use to prevent damage to the metallic material itself and preserve its metallic texture.

The Role of Aluminum Paste in Paints Manufacturing

Our aluminum paste plays a vital role in enhancing various aspects of paints:

Imparting Unique Luster and Color Effects

Aluminum paste allows paints to exhibit unique metallic textures and shimmering effects. In applications such as automotive coatings, industrial paints, and inks, adding aluminum paste imbues the paint with metallic colors, such as silver and gray, significantly enhancing the paint’s aesthetic appeal and decorative qualities.

Enhancing Coating Hiding Power

The flake structure of our aluminum pigment creates a dense shielding layer in the paint. This effectively conceals substrate defects and colors, increasing the paint’s hiding power, reducing paint consumption, and ultimately saving costs.

Improving Coating Protection Performance

The aluminum pigment in our aluminum paste offers excellent chemical resistance. It forms a protective film on the coating surface, blocking external moisture, oxygen, and compounds from corroding the substrate. This significantly boosts the paint’s corrosion resistance and protective capabilities.

Boosting Coating Mechanical Properties

Aluminum paste enhances the paint’s hardness, wear resistance, and adhesion properties, making the coating more durable and resistant to scratches and peeling. This extends the paint’s service life.

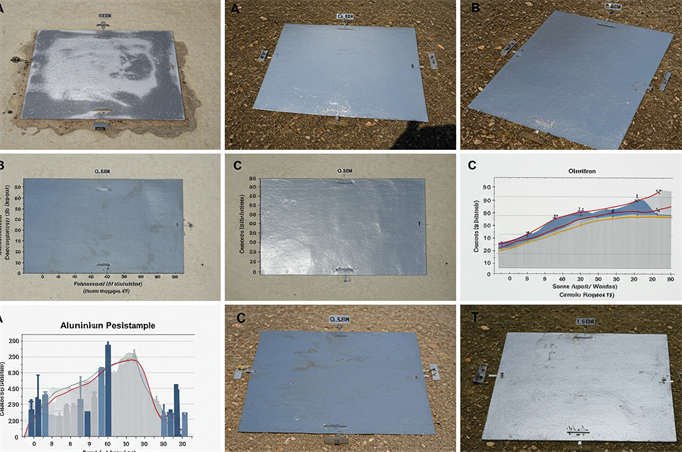

Applications of Aluminum Paste in Paints

We widely use our aluminum paste across numerous paints manufacturing sectors:

Automotive Coatings

We use it to produce various functional automotive topcoats, such as metallic paints and pearl paints. This enhances car exteriors, making them more exquisite and high-end while also improving coating protection and durability.

Architectural Coatings

Adding aluminum paste to interior and exterior wall paints allows us to create artistic coatings with metallic textures, such as imitation aluminum panel effect coatings and metallic fluorocarbon coatings. These not only offer a unique appearance but also provide excellent weather resistance and self-cleaning functions, making them suitable for building exterior decoration and maintenance.

Industrial Coatings

We widely use our aluminum paste for the protection and decoration of metal products, mechanical parts, ships, and containers. It enhances the workpiece’s corrosion resistance and wear resistance, extending its service life.

Inks

We use it to create inks with metallic effects, such as gold and silver inks. These are suitable for packaging printing, decorative printing, and other fields, increasing products’ visual appeal.

Electronic and Electrical Coatings

Adding aluminum paste to electronic device casing coatings not only achieves a metallic appearance but also improves the coating’s electromagnetic shielding performance and thermal conductivity. This is ideal for laptop and mobile phone casings, for example.

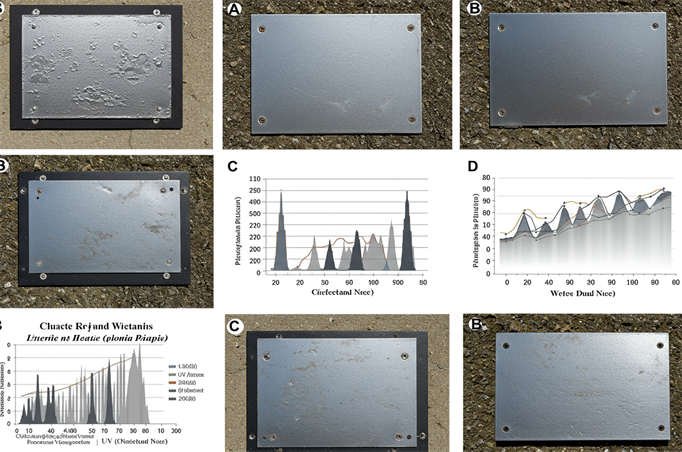

Aluminum Paste Production Processes

We employ advanced production processes to ensure the highest quality aluminum paste:

Dry Grinding Process

This is the earliest method for producing aluminum powder from aluminum ingots, using mechanical crushing and cutting. While this process is simple and efficient, it results in a broad particle size distribution and is prone to residue. We find it suitable for paint types with low aluminum powder particle size requirements.

Wet Grinding Process

This process uses a liquid medium as the grinding environment to grind and disperse aluminum powder. This allows us to obtain aluminum powder with precise particle size and narrower distribution. Additionally, we can adjust the shape and characteristics of the aluminum powder by modifying materials and additives. This method ensures stable product quality and is one of our primary methods for producing aluminum paste.

Atomization Method

We atomize molten aluminum liquid into tiny aluminum particles using high-speed gas or water flow, then obtain aluminum powder through classification and surface treatment. Aluminum powder produced by this method has a high spherical shape, high purity, and a broad particle size distribution, making it suitable for producing high-quality aluminum paste.

Operational Guidelines for Aluminum Paste

To ensure optimal performance and safety, we advise the following operational guidelines for our aluminum paste:

Storage and Transportation

Aluminum paste is prone to mold growth when reacting with oxygen and water in the air. Therefore, ensure packaging is thorough and store it in a dry, cool, well-ventilated warehouse, away from direct sunlight and high temperatures. Handle with care during transportation to prevent packaging damage.

Dosage

Strictly control the dosage of aluminum paste based on the paint type, purpose, and desired effect. The dosage in paint is generally around 1% to 20%. Excessive amounts can lead to increased coating viscosity and prolonged drying times, while insufficient dosage will not achieve the desired metallic effect.

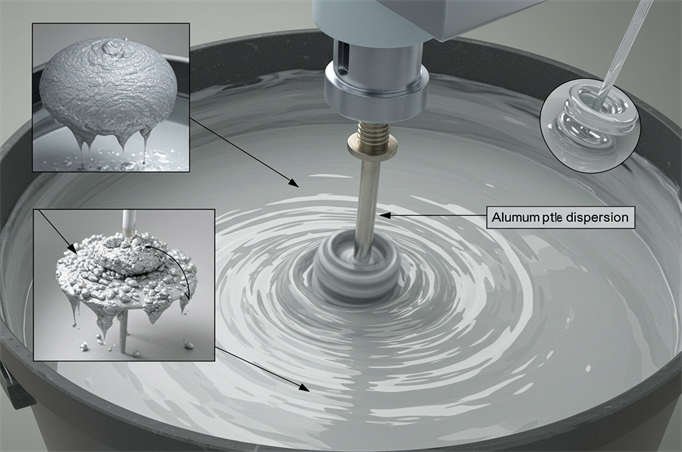

Mixing and Dispersion

When adding aluminum paste to paint, first mix the aluminum paste with an appropriate solvent or additive, then slowly add it to the paint. Disperse it by low-speed stirring to avoid high-speed agitation damaging the aluminum pigment and affecting its performance.

Compatibility

Aluminum paste and other components of the paint, such as resins, solvents, and additives, should have good compatibility. Otherwise, quality issues such as layering, streaking, or wrinkling may occur. Therefore, conduct comprehensive experiments and tests before use to ensure excellent compatibility between all components.

How Much Aluminum Paste Do We Typically Add in Paints Manufacturing?

The proportion of aluminum paste in paint manufacturing varies depending on the type of paint, its intended purpose, performance requirements, and the specific type of aluminum paste used. Here are some standard proportions:

General Recommended Addition Proportions

- General Paints: We generally recommend an aluminum paste addition ratio of around 4%-10% of the total paint quantity.

- Specialty Formula Paints: In some paints requiring strong metallic effects or special properties, the aluminum paste proportion may be as high as 15%-20%.

By Paint Type Classification

- Colored Metallic Paints: The addition ratio of aluminum silver paste is typically 1%-4%.

- Pure Silver Paints: The addition ratio of aluminum silver paste is typically between 4% and 10%.

- Single-Layer Metallic Flash Paints: The additional ratio of aluminum silver paste is approximately 5% to 13%.

- Anti-Corrosion Paints, Can Coatings, and Coil Coatings: The addition ratio of aluminum silver paste is around 10%-13%.

- Exceptional Cases (Aluminum Powder Paste Foam Coatings): The addition proportion of aluminum powder paste can be as high as 15-25 parts (relative to 100 parts of pure acrylic self-crosslinking cationic emulsion).

- Water-Based Paints: The addition proportion of water-based aluminum silver paste generally does not exceed 10%.

- Aluminum Powder Silicone Paints: The amount of aluminum powder used is 0.8% to 1.5% of the formula quantity.

In actual applications, paint manufacturers must determine the optimal proportion of aluminum paste through experiments and tests based on specific formulation requirements, paint performance specifications, and cost factors. At the same time, we ensure that our aluminum paste has good compatibility with other components to guarantee paint quality and performance.

What Kind of Aluminum Paste Factory Should Paint Manufacturers Collaborate With?

When paint manufacturers choose an aluminum paste factory for collaboration, they must thoroughly consider several key factors to ensure that the aluminum paste quality, supply stability, and cost-effectiveness meet their production needs. Here are our specific collaboration requirements:

Production and Supply Capacity

- Production Scale: Paint manufacturers typically have enormous demands, so the aluminum paste factory must have a sufficient production scale. For example, Silver Arrow Aluminum Silver Paste has 5 production plants, with an annual output of over 6,000 tons of aluminum powder and aluminum paste, which can well meet the requirements of large paint manufacturers.

- Supply Stability: We require the aluminum paste factory to have stable raw material supply channels and a robust production process to ensure that aluminum paste can be supplied on time, with quality, and in sufficient quantity, thereby avoiding risks to paint production due to insufficient or interrupted supply.

Product Quality and Performance

- Particle Size and Distribution: The uniformity of aluminum paste particle size affects the paint’s performance and appearance. For instance, our ZYD513 aluminum silver paste, with a D50 of 13 μm, is suitable for agricultural film masterbatches and other products. Paint manufacturers should select aluminum paste with matching particle sizes tailored to the specific paint type and application.

- Purity and Impurity Content: High-purity, low-impurity aluminum paste ensures stable paint quality, preventing quality problems or side effects caused by impurities.

- Metallic Texture and Color: Better metallic texture and color saturation enhance the paint’s decorative and aesthetic appeal. For example, automotive coatings and industrial paints have high requirements for the metallic texture and color of aluminum paste.

- Weather Resistance and Corrosion Resistance: For outdoor paints, aluminum paste should have good weather resistance and corrosion resistance to ensure that the paint maintains its properties and appearance under various environmental conditions.

Technical Research and Development and Innovation Level

- Process Innovation: Advanced production processes improve the performance, quality, and stability of aluminum paste. For example, wet grinding produces aluminum paste with precise and narrower particle size distribution.

- New Product Development Capabilities: We develop a range of particle sizes and performance aluminum paste products, including water-based aluminum silver paste and energy-saving aluminum paste, in response to market demand and the evolving trends in the paint industry.

Qualifications and Certifications

- Enterprise Qualifications: The aluminum paste factory should possess legal business licenses, production licenses, and other qualifications to ensure the legality of its production and operation activities.

- Quality Management System Certification: Certifications such as ISO 9001 demonstrate that the enterprise has a complete quality management process, ensuring product quality stability and consistency.

- Environmental Certification: With increasing ecological requirements, aluminum paste production should comply with relevant environmental standards for wastewater, exhaust gas, and waste treatment. Obtaining corresponding environmental certifications can reduce the collaboration risks for paint manufacturers.

Price and Cost

- Reasonable Pricing: Aluminum paste prices should be sensible and in line with market norms. The factory can offer certain price advantages or flexible pricing strategies to reduce paint manufacturers’ production costs.

- Cost Management: The aluminum paste factory should implement effective cost management, optimizing production processes, enhancing efficiency, and controlling costs to offer paint manufacturers more competitive product prices.

Service and Support

- Pre-sales Service: The aluminum paste factory provides detailed product information, performance parameters, and application suggestions to assist paint manufacturers in selecting suitable aluminum paste products.

- Sales Service: Prompt delivery ensures the timeliness and accuracy of supply, providing customized products and services tailored to the needs of paint manufacturers.

- After-sales Service: A comprehensive after-sales service system enables a quick response and resolution of product quality issues and service guarantee needs that may arise during the use of paint by manufacturers.

Market and Reputation

- Market Share: An aluminum paste factory with a substantial market share generally possesses strong strength and competitiveness, and the market more easily recognizes its product quality and performance.

- Customer Reputation: A good customer reputation is a key factor in measuring the capabilities and credibility of the aluminum paste factory. Inquire about the usage experience and evaluation of other paint manufacturers to understand the aluminum paste factory’s product quality, supply capacity, and service level.

Environmental Protection and Sustainable Development

- Environmentally Friendly Production: The aluminum paste factory should adopt environmentally friendly production processes and equipment to minimize environmental pollution and comply with national and local environmental regulations.

- Sustainable Development Concept: We focus on sustainable development, actively developing and applying energy-saving materials and renewable energy, reducing energy consumption and carbon emissions in production, and achieving shared economic, social, and environmental benefits.

As we conclude this exploration into the world of aluminum paste for paints manufacturing, Five Star New Materials stands ready to be your partner of choice. Our commitment to excellence is reflected in every batch of aluminum paste we produce, ensuring that your paint formulations benefit from superior performance, enhanced aesthetics, and reliable protection.

We’ve highlighted the critical role of aluminum paste in elevating the quality and functionality of paints. From providing that distinctive metallic sheen and improving opacity to boosting corrosion resistance and physical properties like hardness and adhesion, our aluminum paste is a multifaceted additive that addresses the multifarious needs of the paints manufacturing industry.

At Five Star New Materials, we don’t just supply aluminum paste; we offer a comprehensive solution. Our state-of-the-art production facilities, stringent quality control measures, and a team of dedicated professionals ensure that you receive a product that meets the highest benchmarks. We take pride in our ability to customize our aluminum paste to match your specific requirements, whether it’s particle size distribution, purity levels, or specific performance attributes.

Moreover, we recognize the significance of sustainability in today’s business environment. Our production processes are designed with environmental responsibility in mind, minimizing our carbon footprint and ensuring that our products comply with global environmental regulations. This aligns with our vision of supporting a greener future while delivering top-tier materials for your paints manufacturing endeavors.

We invite you to experience the Five Star New Materials difference. Our goal is to empower your business with high-quality aluminum paste that drives Innovation and excellence in your paint products. For more information on how our aluminum paste can enhance your paints manufacturing process, visit our website or contact our expert team. Together, let’s create paints that not only meet but exceed industry standards and customer expectations.

Are you looking for a reliable partner for your paint manufacturing needs? Connect with Five Star New Materials to discover how our aluminum paste can elevate your products.