You will see many key ingredients in aluminum paste. Aluminum powder or flakes give it a shiny look. Carrier solvents mix everything together. Additives, like fatty acids and surfactants, help keep it stable and bright. In 2025, there is a big change to water-based and eco-friendly mixes. Many companies now use these new ingredients in aluminum paste. This helps lower damage to the environment.

- Water-based carriers

- Low-VOC solvents

- Advanced surfactants for better mixing

Key Takeaways

- Aluminum paste has aluminum flakes, carrier solvents, and additives. Each part is important for shine and stability.

- In 2025, eco-friendly aluminum pastes are more common. Water-based and low-VOC solvents help the environment. They also make things safer.

- Picking the right aluminum paste is important. Leafing paste gives a shiny look. Non-leafing paste sticks better and is more flexible.

- Safety matters when using aluminum paste. Always wear safety gear. Keep it in a cool, dry place. Keep it away from water to stop bad reactions.

- Keep learning about new rules and ingredient trends. This helps you make smart choices for your projects. It also helps you follow safety rules.

Ingredients in Aluminum Paste

Aluminum Powder and Flakes

Aluminum powder and flakes are the main parts of aluminum paste. These small pieces make paints and coatings look shiny and metallic. There are two types you can pick from: leafing and non-leafing. Leafing aluminum paste stays on top and gives a bright, shiny finish. Non-leafing aluminum paste spreads out and sticks well to surfaces. It also mixes with other colors.

Here is a table that shows how leafing and non-leafing aluminum paste are different:

| Feature | Leafing Aluminum Paste | Non-Leafing Aluminum Paste |

|---|---|---|

| Description | Aluminum flakes stay on top because of low surface tension. | Aluminum flakes mix in and spread through the paint. |

| Characteristics | 1. Very shiny and looks like chrome 2. Flakes stay on top 3. Protects against rust | 1. Spreads out in the paint 2. Sticks well to surfaces 3. Works with many colors |

| Applications | 1. Used for roofs and tanks that need strong protection 2. Used in cars and furniture for a shiny look | 1. Used in cars, furniture, and electronics 2. Used in many kinds of paints |

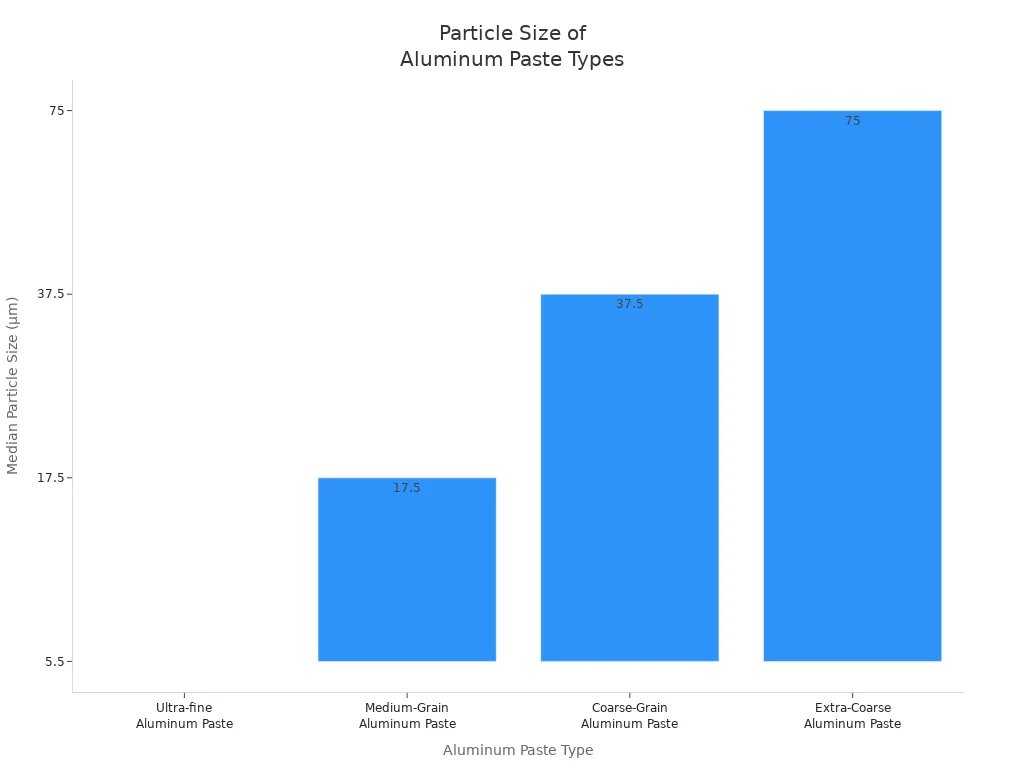

The size of the aluminum flakes changes how the paste looks and works. Very small flakes (1–10 µm) make car paints and inks look smooth and shiny. Medium flakes (10–25 µm) and big flakes (25–50 µm) give different looks, like sand silver or thick coverage for walls and roofs. Extra-large flakes (50–100 µm) help keep heat out and work well for tough coatings.

It is important to check the flake size and type before you pick aluminum paste for your project.

Carrier Solvents

Carrier solvents help mix and spread aluminum flakes in the paste. There are a few kinds used today:

- Aliphatic hydrocarbons

- Aromatic hydrocarbons

- Ketones

- Alcohols

Each solvent has its own good points. Aliphatic hydrocarbons are good for most uses and do not smell much. Aromatic hydrocarbons make things shinier but are not as safe for the planet. Ketones and alcohols dry fast and are good for quick jobs. You should choose a solvent based on what you need, like how fast it dries, how safe it is, and if it is good for the environment. Many new aluminum pastes use water-based or low-VOC solvents to help protect nature.

Additives and Enhancers

Additives and enhancers make aluminum paste work better and safer. Fatty acids and fatty acid alkanolamides help flakes stay mixed and stop clumps. Nonionic surfactants help mix everything and keep the paste smooth. Diethylene glycol helps keep the paste stable and controls drying. Lithium soap makes the paste feel better and spread easier. Some pastes even have copper flakes for special looks.

Here is a table with safety tips for using these ingredients:

| Safety Measure | Description |

|---|---|

| Mixing with Water | Do not mix aluminum paste waste with water or other chemicals. This can be dangerous. |

| Fire Suppression | Use dry sand or Class D dry agents to put out fires. Never use water on aluminum paste fires. |

| Personal Protective Equipment | Wear a dust mask, safety goggles, gloves, and protective clothes to stay safe. |

Tip: Always follow safety rules when you use aluminum paste ingredients. Wear safety gear and keep chemicals in a safe place.

It is also important to check quality. Makers test the materials and finished paste to make sure they are safe and good. They use ISO and ASTM rules to check for safety and quality.

Functions of Each Ingredient

Metallic Effect and Appearance

Aluminum flakes make paints and coatings look shiny. The size and shape of flakes change how the surface looks. Small flakes give a smooth finish. Large flakes make the coating bright and shiny. How you mix and grind the flakes changes the look too. Leafing aluminum paste gives a chrome shine. Non-leafing types make a softer, satin look. All the ingredients work together to make these effects. You can use aluminum paste in car paint, building coatings, and printing inks.

Tip: Pick the right flake size and type for your project’s look.

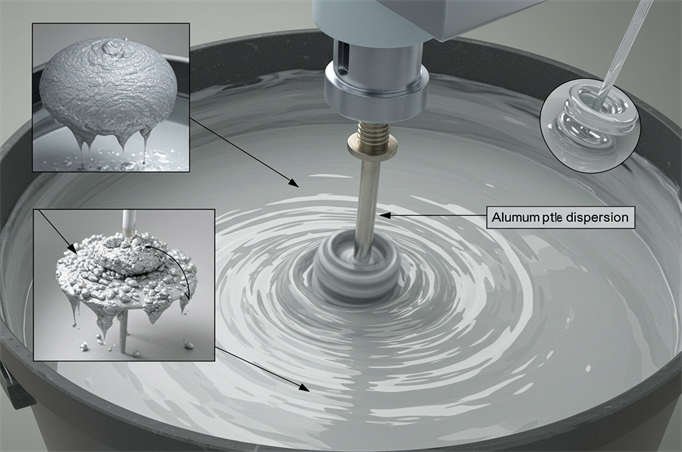

Stability and Dispersion

You need a stable paste for good results. Fatty acid alkanolamides and nonionic surfactants help spread the flakes. Too much fatty acid alkanolamide makes the paste less stable in water. The best results come from using the right amount of additives. Here are some key points:

- Fatty acid alkanolamides and nonionic surfactants help flakes spread in water.

- Using too much fatty acid alkanolamide lowers stability.

- Balanced ingredients keep the paste smooth and easy to use.

Always check the mix to make sure the paste stays stable when stored and used.

Application Performance

How you mix ingredients changes how aluminum paste works. The way flakes sit, the solvent type, and the size all matter. Here is a table that shows how leafing and non-leafing aluminum paste work:

| Feature | Leafing Aluminum Paste | Non-Leafing Aluminum Paste |

|---|---|---|

| Flake Orientation | Floats to the surface | Spreads through the film |

| Appearance | Bright, chrome-like shine | Softer, satin metallic look |

| Key Property | Great barrier protection | Great intercoat adhesion |

| Typical Use Case | Roof paint, protective coatings | Car basecoats, industrial uses |

You find aluminum paste in car paint, building coatings, plastics, and inks. The right mix of ingredients gives the best results for each use. Water-based aluminum paste is popular now because it is safer and better for nature.

New Trends for 2025

Eco-Friendly Formulations

In 2025, you will find more eco-friendly aluminum paste. Many companies use water-based formulas and low-VOC solvents now. These changes help keep people and nature safe. Water-borne aluminum pastes make fewer harmful fumes. They also make cleaning up easier and safer. Manufacturers use green chemistry to choose safer materials. This change helps meet new building rules for safer products. Non-leafing pastes last longer and stand up to weather better. You do not need to use them again as often, so you save time and resources. These updates help you reach sustainability goals and cut down on waste.

Advanced Additives

You will see new additives in aluminum paste. Advanced surfactants help flakes mix well and stay stable. Some pastes have special coatings to keep the metallic look bright. Companies now avoid harmful solvents like benzene and ketones. They use ingredients that do not leave a smell or residue after printing. High-temperature resistance is important too. This means the paste can handle heat without making bad substances. You can see these changes in food packaging, where safety rules are strict. The table below lists some important standards for safer aluminum paste:

| Standard | Description |

|---|---|

| EU RoHS Directive | Limits hazardous substances in packaging materials |

| Benzene-Free & Ketone-Free | Avoids harmful solvents for better health |

| FDA Compliance | Meets safety rules for food contact materials |

| Low Odor | Prevents food tainting after printing |

| High-Temperature Resistance | Withstands sterilization without harmful release |

Regulatory Changes

You need to know about new rules in 2025. Governments now check aluminum content and where it comes from. You must show where your raw materials are from and follow new customs rules. Many companies use more than one supplier and work with local partners to avoid import problems. Research teams design pastes that can change ingredients if needed. This helps you keep up with new laws and market needs. The market for aluminum paste is growing because of recycling, lightweight materials, and big building projects. You will see more focus on safe, low-carbon, and recycled ingredients in the future.

Tip: Keep up with new rules and ingredient trends to make the best choices for your projects.

Safety and Handling

Chemical Reactivity

Aluminum paste can react with water or other chemicals. Mixing it with water causes a strong reaction. This reaction makes heat and gas. It can lead to fires or explosions. One time, workers did not keep water away from aluminum paste. A big fire happened and the building was damaged. Always check for water before you blend or store aluminum paste.

Here is a table that shows some chemical reactivity concerns and incidents:

| Incident Description | Chemical Reactivity Concern | Outcome |

|---|---|---|

| Explosion at Napp Technologies | Aluminum paste reacted with water | Fire and explosion |

| Abnormal blending conditions | Not knowing chemical hazards | Poor emergency response |

| Water-reactive substances present | Self-sustaining reactions | Explosion due to ignored warning signs |

| Poor hazard analysis | Exothermic reactions at low temperatures | Failure to remove water led to accidents |

⚠️ Keep aluminum paste away from water and moisture. Use dry tools and containers.

Storage and Disposal

Store aluminum paste in a cool and dry place. Good airflow keeps the air safe. Do not keep aluminum paste near water or heat. Use sealed containers to block moisture. If you need to throw away aluminum paste, follow local rules. Many places need special ways to treat waste and leftover paste.

Here is a table with recommended practices:

| Practice Type | Recommendation |

|---|---|

| Storage | Store in cool, dry, well-ventilated areas |

| Disposal | Follow local environmental regulations |

Safety at work is important. In aluminum jobs, injury rates are 2.5 for every 100 workers. Accidents can cost up to $50,000 each. Most companies train workers and follow safety rules. You should wear gloves, masks, and goggles when you use aluminum paste. Training helps you avoid mistakes and keeps everyone safe.

- The Molten Metal Incident Report tells stories about accidents in aluminum places.

- These reports help you learn how to stop hazards and make safety better.

🛡️ Tip: Always wear protective gear and follow safety rules. Good storage and disposal keep you and the environment safe.

Aluminum paste has aluminum flakes, carrier solvents, and additives. Each part helps in a special way. You get heat reflection, save energy, and a shiny look. The table below shows how aluminum paste is useful:

| Benefit/Application | Description |

|---|---|

| Heat-reflective properties | Keeps metal safe and makes buildings strong. |

| Energy efficiency | Lowers heat in buildings and saves on cooling. |

| Light absorption | Helps solar cells work better by bouncing more light. |

You should mix it safely and watch the powder ratio. Keep water away from aluminum paste. Pick eco-friendly types and follow safety steps. New ingredients in 2025 help you get good results and protect nature.

FAQ

What are the main ingredients in aluminum paste?

Most aluminum pastes have aluminum flakes, carrier solvents, and additives. These ingredients work together. They make the paste shiny. They help keep it stable. They also make it easy to use.

Can you use aluminum paste in water-based paints?

You can use aluminum paste in water-based paints. Many new formulas use water as the main carrier. This makes the paste safer for people. It is also better for the environment.

How do you store aluminum paste safely?

Keep aluminum paste in a cool, dry place. Use sealed containers to block moisture. Always keep it away from heat and water.

Is aluminum paste safe for home use?

Aluminum paste is safe if you follow safety rules. Wear gloves and goggles. Do not let it touch water. Always read the safety instructions before you use it.

Why do some aluminum pastes look shinier than others?

The size and shape of aluminum flakes change how shiny the paste looks. Smaller flakes give a smooth look. Bigger flakes make the finish brighter and more reflective.