You may think aluminum paste chemical formula works well for coatings. It gives strong reflectivity, stops corrosion, and has a shiny look. The cost can go up or down with the market. You might have problems when you use it, especially in water-based systems. Before you pick it, look at your project’s needs and the kind of aluminum paste. Think about things like how you prepare the surface, how you mix it, how you put it on, and safety steps. This helps you get the best results.

Key Takeaways

- Aluminum paste makes coatings shiny and tough. It helps stop rust and damage. This is good for projects that need to last long and look bright.

- Pick the right aluminum paste for your job. Leafing paste gives shine. Non-leafing paste makes things strong. Water-based paste is better for the planet. Match the paste to what your project needs.

- Test a little aluminum paste first. This helps you find problems early. Make sure it works with your coating before using more.

- The price of aluminum paste can change. Plan your money so you do not get surprised by costs.

- Use safety rules when you work with aluminum paste. This keeps you safe and helps the earth. Store and throw away aluminum paste the right way.

Quick Overview

Main Pros and Cons

Aluminum paste chemical formula gives coatings some big benefits. It makes surfaces shiny and helps them stay cool. It also helps stop metal from rusting, so things last longer. The paste helps coatings stand up to sun and bad weather. Many people like how it makes cars and machines look metallic.

But there are some problems too. The price of aluminum paste can go up or down. This means you might have to change your budget. Some kinds do not work well with water-based systems. This can make it hard to pick the right one. You might have trouble putting it on, like getting lumps or rough spots. People also worry about the environment if they want a green choice.

Tip: Try a small amount first before using aluminum paste on your whole project. This lets you find problems early.

Best Use Cases

Aluminum paste is best for coatings that need to look good and work well. It is used a lot in car paints to make them shiny and stop rust. Factories use it to protect machines from rain and sun. It also makes decorative paints look bright and metallic. Market data shows it is very helpful in these uses. Companies use it in eco-friendly and water-based coatings as they try to be greener.

If you want a coating that lasts, looks nice, and shines, aluminum paste chemical formula is a good pick. You should use it for projects that need strong protection and a modern look.

Aluminum Paste Chemical Formula in Coatings

Types of Aluminum Paste

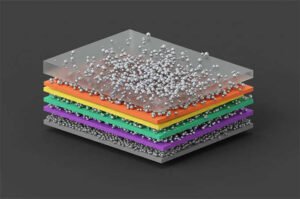

There are different kinds of aluminum paste for coatings. Each kind works in its own way and gives special results.

- Leafing aluminum paste floats on top of the coating. It makes a shiny and reflective layer. People use it in decorative paints for a bright metallic look.

- Non-leafing aluminum paste spreads through the whole coating. It gives a smooth and even look. This type sticks well and lasts longer, so it is good for protection.

- Water-based aluminum paste is best for eco-friendly coatings. It does not smell strong and is easy to clean up. You pick this type when you want a safer and greener choice.

Note: Choosing the right aluminum paste chemical formula helps you get the look and strength you need for your project.

Chemical Properties

Aluminum paste chemical formula gives coatings special features. The main part is aluminum powder. Makers mix it with solvents and other things to make a silver-grey metallic paste. It does not dissolve in water, but it mixes with organic solvents. The paste stays stable if you store it right.

Here is a quick look at the chemical makeup:

| Chemical Name | Aluminium Pigment |

|---|---|

| Molecular Formula | Al |

| Appearance | Silver-Grey Metallic Paste |

| Solubility | Insoluble in water, soluble in organic solvents |

| Composition | Aluminium Powder, Solvent, Additives |

| Reactivity | Stable under recommended storage conditions |

Aluminum paste chemical formula gives coatings their shine and strength. How you use it depends on the type and its chemical properties. You can get a glossy look, strong protection, or a safer water-based choice.

Advantages

Reflectivity

Aluminum paste makes coatings reflect light very well. The small flakes in the paste bounce light off surfaces. This makes things look shiny and bright. Surfaces stay cooler because they reflect sunlight. You see this on car paint, metal roofs, and outdoor gear. Reflective coatings help objects stand out and look nice.

Tip: Using reflective coatings can help save energy. They keep buildings cooler in sunny places.

Corrosion Resistance

Aluminum paste chemical formula protects coatings from rust and corrosion. When you use it, aluminum flakes make a shield. This shield stops water and air from touching the metal. That helps keep rust away.

- Experts at the Naval Air Warfare Command made a coating with aluminum pigment. It replaces chromate solutions and fights corrosion.

- Non-chromated varnishes with aluminum paste meet aviation rules for some aluminum grades. They show strong protection against rust.

- Chromate pigments’ anti-corrosion power is now in varnishes without chromate. This is because of special chemical additives.

Aluminum paste keeps metal safe in tough places like factories, ships, and outside buildings.

Adhesion

Adhesion means how well the coating sticks to things. Aluminum paste comes in different types. Each type has its own sticking power. You need to choose the right one for your job.

| Type of Aluminum Paste | Adhesion Properties | Applications |

|---|---|---|

| Leafing Aluminum Paste | Weaker adhesion due to flake structure | High-gloss coatings, anti-corrosion coatings |

| Non-Leafing Aluminum Paste | Strong adhesion and stability | Automotive coatings, furniture, electronics |

Non-leafing aluminum paste sticks better and lasts longer. It works well for cars, furniture, and electronics. Leafing aluminum paste is best for shiny looks but does not stick as well.

Weather and UV Resistance

Aluminum paste helps coatings last in sun and bad weather. The flakes protect paint from UV rays. UV rays can make paint fade and break down. Car paint and outdoor coatings use this benefit.

- Silk light aluminum paste makes car finishes look and work better.

- Weather resistance keeps paint safe from UV rays. Paint does not fade or age fast.

- Uvecoat 2200-based coatings keep over 65% of their shine after 7,000 hours in the sun. This is much better than regular coatings.

Aluminum paste helps surfaces stay new, even after years outside.

Aesthetic Effects

Aluminum paste gives coatings a cool look that people like. You can make shiny, metallic, or matte finishes. This helps products look special and modern.

| Aesthetic Effect | Description |

|---|---|

| Metallic Finish | Makes surfaces shiny and metallic. |

| Unique Metallic Texture | Adds a special feel, good for cars and buildings. |

| Decorative Finish | Works for matte or glossy styles, fits many designs. |

| Aging Resistance | Keeps the nice look for a long time, even outside. |

| UV Resistance | Helps coatings stay shiny and bright in strong sun. |

- Non-leafing aluminum paste makes metallic shine and lasts longer.

- It makes outside wall coatings look better and stronger.

- Car makers and builders use it to make things look great.

Durability

Coatings with aluminum paste last longer than most others. You get a strong finish that stands up to weather and wear. Studies say these coatings last for many years.

| Source | Lifespan Estimate |

|---|---|

| The Wheel Shop | 15 to 20 years |

| Wheels Doctor | 3 to 10 years |

You can expect a finish that lasts a long time with aluminum paste chemical formula. It is a smart pick for projects that need to look good and stay strong.

Disadvantages

Cost

Aluminum paste often costs more than other pigments. The price can change a lot because of the world market. If raw aluminum gets more expensive, coatings cost more too. Sometimes, it is hard to get aluminum paste because of supply problems. This can slow down your project or make you pick something else. If your project is big, these costs can add up fast.

Tip: Check prices before you start your project. This helps you plan your money and avoid problems.

Compatibility

You need to make sure aluminum paste fits your coating system. If you use the wrong binder or primer, the metallic look might go away or the color might change. Some primers can change how the paste sticks or looks. You must choose a topcoat that works with the paste.

- The aluminum paste must work with the coating system or you might lose the metallic look or see color changes.

- Some primers can change how the paste sticks or looks, so you need to pick a good topcoat.

If you skip this step, your coating might not look good or last long. Always test a small spot first to check for problems.

Environmental Concerns

Aluminum paste can cause health and environmental problems. Tiny aluminum flakes can float in the air and make it hard to breathe. Workers should wear masks and use fans to stay safe. Aluminum powder can catch fire easily. You need special ways to store and handle it to stop fires.

- Health Concerns: Tiny flakes can get in the air and hurt workers’ lungs.

- Fire Hazard: Aluminum powder can catch fire, so you need to be careful.

- Environmental Impact: If you throw it away the wrong way, it can hurt water and soil.

If you do not throw away aluminum paste the right way, it can harm rivers, lakes, and dirt. Always follow local rules for waste and safety.

Application Challenges

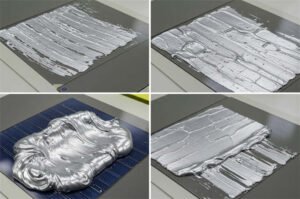

You may have problems when using aluminum paste in coatings. These problems can change how your coating looks and works.

| Challenge Type | Description |

|---|---|

| Regulatory Compliance | You must follow strict rules about heavy metals and emissions. This means more tests and paperwork. |

| Formulation Stability | Some aluminum pastes do not mix well with other parts. You may need to change your formula to keep it stable. |

| Performance Characteristics | New binders and additives can help coatings, but they can also make things harder. |

You might also have these problems:

- Prices for raw materials can change a lot

- Supply chain problems

- Tough rules about heavy metals and emissions

Problems can include bad leafing, mixing trouble, bubbles in water-based paints, and uneven shine. You might also see flakes settling or poor sticking.

If you do not fix these problems, your coating might not pass quality checks.

Surface Defects

Aluminum paste can cause surface problems if you do not use it right. You might see uneven color, dull spots, or rough places. These problems often come from how the paste mixes or reacts with other parts.

- If the particle sizes are not even, the color can look bad and not spread well.

- Bad leafing or non-leafing can make the finish dull and not smooth.

- If it reacts with water or air, it can lose shine or even catch fire.

- If it does not fit with resins or binders, you can lose shine or the paint can gel.

- If it settles or has a short shelf life, it can be hard to use and not last long.

- Problems with color and shine can make customers unhappy and cause complaints.

You can stop many of these problems by following the maker’s instructions and testing your formula first. Always keep aluminum paste in a dry, cool place so it stays good for your next project.

Comparison

Aluminum Paste vs. Other Pigments

When you pick a pigment for coatings, you want to know how it works. Aluminum paste chemical formula gives a strong metallic shine and lasts a long time. It makes surfaces look bright and shiny like a mirror. The flakes in the paste bounce sunlight away. This keeps your coating cool and helps it not fade fast. Pearlescent pigments make a soft shimmer and can change colors. But they do not last as long or protect from UV rays like aluminum paste.

You also need to think about safety. Using aluminum paste means you must be careful. Keep it away from things that can catch fire. Store it in dry, closed containers. Always use tools that do not make sparks. Do not use open flames near it. Move aluminum powder slowly so you do not make dust clouds. These steps help stop fires and keep you safe. Other metallic pigments may be safer, but you should always check their safety rules.

The price can change depending on the pigment type. Aluminum paste usually costs more than simple pigments. But it gives better protection and lasts longer. Pearlescent pigments may cost less. You might need to paint again sooner if you use them.

Here is a quick look at how aluminum paste and pearlescent pigments compare:

| Characteristic | Aluminum Paste | Pearlescent Pigment |

|---|---|---|

| Reflectivity | High metallic shine | Soft shimmer, color-shifting glow |

| Durability | High durability, scratch and UV resistant | Less durable, not as tough as aluminum paste |

| UV Protection | Strong | Moderate |

| Cost | Higher | Moderate |

| Safety | Needs careful handling and storage | Usually less strict, but still needs care |

Tip: Always read the safety instructions for any pigment you use. This helps keep you and your project safe.

Summary Table

Here is a summary of the main pros and cons for quick reference:

| Feature | Aluminum Paste Chemical Formula | Other Metallic Pigments |

|---|---|---|

| Shine | Very high | Moderate to high |

| Durability | Excellent | Varies |

| UV/Weather Resistance | Strong | Moderate |

| Cost | Higher | Lower to moderate |

| Safety | Needs strict handling | Usually less strict |

| Application | Can be tricky | Often easier |

| Environmental Impact | Needs careful disposal | Varies |

You can use this table to help you pick the best pigment for your project.

Recommendations

When to Use Aluminum Paste

If you want your coating to last and look nice, aluminum paste is a good choice. It works well when you need a shiny look, strong protection, or a modern style. Use it for jobs that face bad weather, need to reflect sunlight, or must stop rust. Car paint, roof coatings, and machines often use aluminum paste for these reasons.

Here is a table to help you choose the right type:

| Type of Aluminum Paste | Key Characteristics | Best Applications |

|---|---|---|

| Leafing | Makes a shiny layer, blocks water and UV rays | Roof coatings, paints for machines, shiny coatings |

| Non-leafing | Spreads evenly, sticks better between layers | Car basecoats, coatings with many layers |

| Water-based | Has less VOC, better for the environment | Decorative paint, protective coatings |

Tip: Pick the aluminum paste that fits your project. Leafing paste gives a bright shine and keeps out water. Non-leafing paste sticks well and lasts longer. Water-based paste is safer for nature.

You should also follow some best steps when using aluminum paste. Check the float value to see how well it protects. Pick the right particle size for a smooth look. Test the paste with your binder to make sure they work together. Mix it well and keep the area dry for the best results.

| Best Practice | Description |

|---|---|

| Match float value | Use the right float value for your needs; high float is best for tough jobs. |

| Consider particle size | Pick the right size for even shine and good coverage. |

| Verify compatibility | Test if the paste works with your binder before using it. |

| Control environmental factors | Watch how you mix, the solvent, and the air’s wetness. These things change how the paste works. |

Note: Try a small batch before you use aluminum paste on a big job. This helps you find problems early and saves time.

Alternatives

Sometimes, aluminum paste is not the best pick. You might want a different look, lower price, or something easier to use. There are other coatings that can also reflect light or protect well.

| Coating Type | Description |

|---|---|

| Anodizing | Makes the surface tougher and stops rust and wear. |

| Powder Coating | Adds a strong layer that does not scratch or fade easily. |

| Electroplating | Covers aluminum with a thin metal layer for better looks and rust protection. |

| Nano-Ceramic Coatings | Makes the surface very hard and tough by bonding at the tiny level. |

| Plasma Electrolytic Oxidation | Gives special features and is better than some old methods. |

You can use anodizing to stop rust. Powder coating gives a tough finish that does not scratch much. Electroplating makes things look better and last longer. Nano-ceramic coatings add extra hardness. Plasma electrolytic oxidation gives special features for advanced needs.

👍 Pick another coating if you want to save money, make it easier, or need special features. Always check if the coating is right for your job.

You can get great results by picking the best coating for your needs. Think about how long you want it to last, how it should look, and if it is safe to use. Test your choice before you start the whole job. This helps you avoid mistakes and get the best finish.

Aluminum paste makes coatings shiny and strong. It helps them last in bad weather. You might pay more to use it. There can be problems when you put it on. Safety is also important. To see if aluminum paste is right for your project, do these things:

- Look at the technical data sheet and batch certificate.

- Talk to the supplier about what you need.

- Read safety rules and learn how to store it.

- Try it with your coating system to check if it works.

You can find more information here:

- Aluminum Paste: Everything You Need to Know

- Applications of Aluminum Paste

- Choosing Aluminum Paste for Automotive Paint

FAQ

What is aluminum paste used for in coatings?

Aluminum paste makes coatings look shiny and strong. It helps stop rust and keeps sunlight from hurting surfaces. People use it on car paint, roofs, and for decoration.

Can you mix aluminum paste with water-based paints?

Some aluminum paste types can go in water-based paints. Water-based aluminum paste is best for green coatings. Always try a small amount first to see if it works.

Is aluminum paste safe to handle?

You need to wear gloves and a mask when using aluminum paste. The powder can make it hard to breathe and might catch fire. Keep it in a dry, closed container to stay safe.

Tip: Always read the safety rules before you start working.

How do you prevent surface defects when using aluminum paste?

Mix the paste well and pick the right binder. Test your mix before painting a big area. Keep your work area dry and clean to stop lumps and rough spots.

What are good alternatives to aluminum paste?

You can use powder coating, anodizing, or nano-ceramic coatings. These choices protect well and look different. Choose what fits your project and how much you want to spend.

| Alternative | Main Benefit |

|---|---|

| Powder Coating | Strong, does not scratch easily |

| Anodizing | Stops rust, lasts a long time |

| Nano-Ceramic | Very hard, modern style |