What is DEG Aluminium Paste

DEG aluminium paste is indeed a material that plays an important role in the production of lightweight concrete

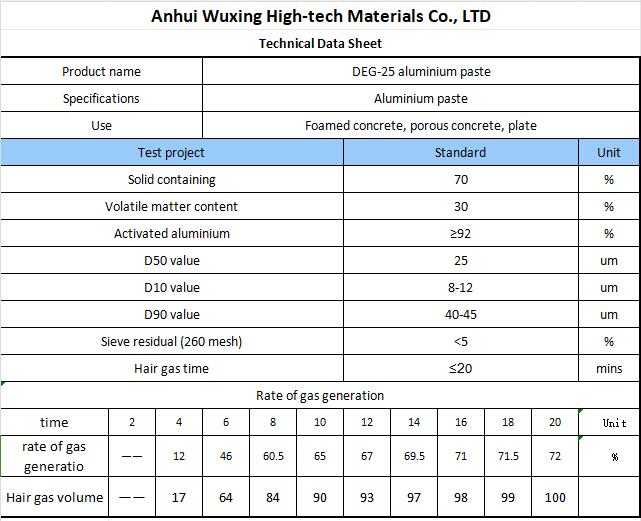

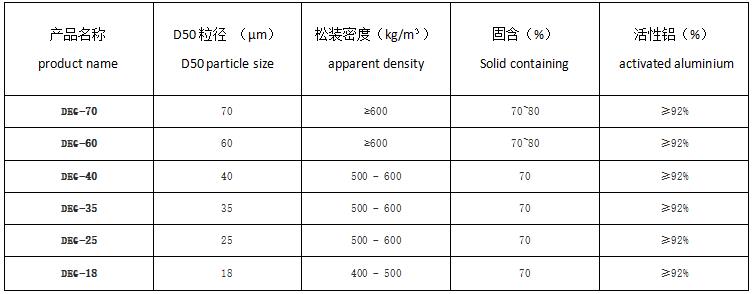

The main component of DEG aluminium paste is aluminium flakes, which are mixed in a mixer to form a homogeneous slurry. These pastes have an aluminium content of up to 70-80%, turning them into efficient lightweight concrete additives. The lightweight nature of aluminium significantly reduces the density of the concrete, which in turn improves its thermal and insulation properties.

A distinctive feature of DEG aluminium paste is that it is moisture-free. This is mainly due to the use of diethylene glycol (DEG) in the production process, which is a highly soluble and safe organic solution that prevents the depletion of water in aluminium pastes. As a result, DEG aluminium pastes are less susceptible to mould growth during storage and maintain a long expiry date even at high temperatures.

DEG aluminium pastes have special advantages in hot climates. Due to the high temperatures and humidity in such areas, mould often grows during storage and transportation of conventional aluminium pastes containing water, which can lead to reduced performance or even render them unusable. Because DEG aluminium paste does not contain water, it can be maintained for a long time in all kinds of harsh environments, ensuring a smooth lightweight concrete production process.

DEG aluminium paste as an efficient and stable lightweight concrete additive has significant advantages in areas with hot climates. Its extensive use not only improves the concrete performance, but also reduces the cost and promotes the steady development of the lightweight concrete industry.