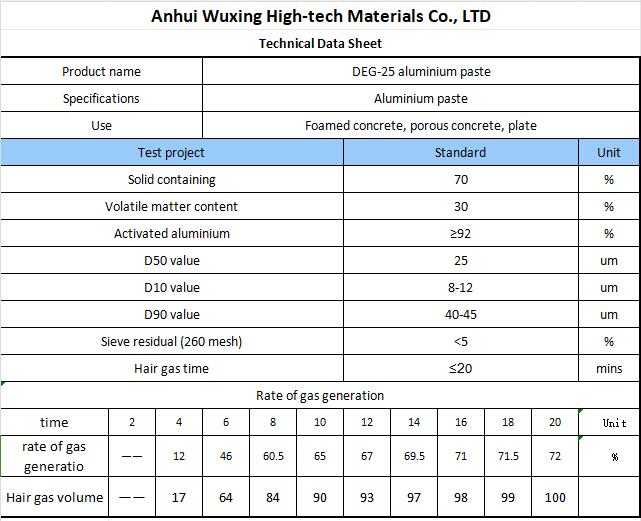

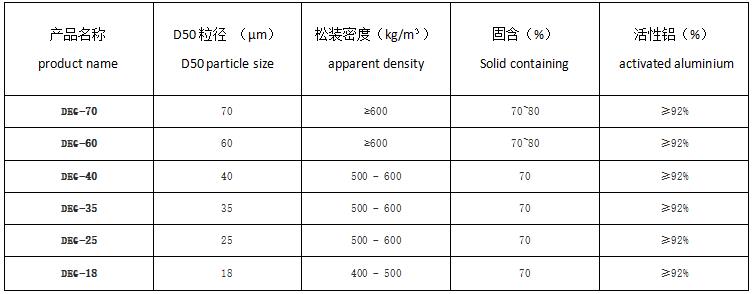

The aluminium powder content in lightweight concrete aluminium pastes has the following effects on performance

1.Density and weight: the increase of aluminium powder content, the amount of hydrogen produced by the aluminium paste in the concrete increases, leading to an increase in the number of bubbles inside the concrete, thus reducing the density and weight of the concrete.

2.Strength: the right amount of aluminium powder can improve the compressive strength of concrete, because the aluminium powder particles can fill the tiny pores in the concrete, reduce the porosity and improve the compactness. However, when the content of aluminium powder is too high, too many bubbles may lead to loose internal structure of concrete, but reduce the strength.

3, durability: aluminium powder and other components in the concrete reaction, can form new cementitious materials, help to improve the durability of concrete. However, too much aluminium powder may produce unfavourable chemical reactions, affecting durability.

4, Thermal insulation: the increase of bubble structure improves the thermal insulation of concrete, the higher the content of aluminium powder, the better the thermal insulation effect may be.

5.Constructability: the right amount of aluminium powder can improve the fluidity and workability of concrete, and improve the construction efficiency. However, too much aluminium powder may cause the concrete to be too loose, which is not conducive to construction.