Offsetting printing ink is a material widely used in the printing field. It is a special ink, and the main ingredients include aluminum silver paste and dispersion, which is usually used for printing food packaging, cosmetics packaging, high-grade decoration wallpaper, gift boxes, medicine packaging, tobacco and alcohol packaging, etc.

Five Star Materials has an extensive range of experience in producing high-quality innovations and solutions including offset printing aluminum paste. The company is comprised of a skilled team with the utmost professionalism to carry great capabilities in meeting the different range of demands and requirements. The versatile offset printing aluminum paste can be applied in a variety of printing applications like commercial, packaging, and labeling, therefore it is widely useful for countless applications.

Offset Printing Ink is an effect pigment with unique properties, which has good dispersion, which can make the printing pattern look smooth and particle-free. At the same time, the ink has rapid volatile, low odor, and water resistance and other characteristics.

When printing with offset printing aluminum ink, its excellent covering power and white brightness, make the print more visually attractive. In addition, due to the environmental advantages and storage resistance of aluminum silver paste, it has a wide application prospect in some packaging and printing fields with high environmental protection requirements, such as tobacco packaging, pharmaceutical packaging, and food packaging.

At Five Star Materials, we truly believe in setting the right standards for the best value for money and quality. We make sure to create innovative solutions to improve the way of living and better aesthetics of products, structures, and more.

The offset printing aluminum paste is made of high-quality raw material which is finely grounded and suspended in a solvent. This paste is a type of ink with a wide variety of usage for its metallic finish that flow smoothly and evenly. Each production is carefully managed by professionals to meet the final standards of offset printing aluminum paste before it could be distributed in the market and channels.

For better quality results of our offset printing aluminum paste, they further undergo a series of tests for inspection of purity, gloss, durability, and others. We make sure the worth of your money will match the attributes of the product for your convenience and satisfaction.

We suggest you to communicate with us fully before purchasing, we will certainly consider all aspects and provide a fair and reasonable price plan. By choosing us, you will get the best product and the best value for your money.

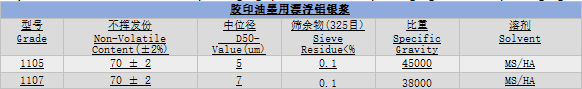

Offset Printing Aluminum Paste has various particle sizes and purities with varying prices depending on its specification. Customers will have to provide the accurate specification needs of their application for us to estimate the costs of the product.

The larger the quantity purchased, the lower the unit price will be. Bulk orders allow us to better share our production and operating costs, so we are happy to offer discounted prices for bulk purchases.

The timing and method of payment you choose will also affect the price. For example, paying in full upfront can result in a more favourable price, as it reduces our cost of capital. Please discuss the most suitable payment option with our sales team.

Transport and logistics are also factors that affect the total cost of ownership. Different modes of transport and destinations will incur different shipping costs. Duties, insurance and other costs also need to be taken into account. By calculating these factors in advance of purchase, you can more accurately estimate the total cost.

At Five Star Materials, our Offset Printing Aluminum Paste is produced in a delicate and rigorous process. Below is our basic production process:

We purchase high purity raw materials from trusted suppliers to ensure the quality of our products from the source.

The raw material is crushed to convert the aluminium blocks into tiny particles for subsequent processing.

The crushed aluminium powder is mixed with our specially formulated solvents and additives and then blended through a high speed mixing process. This step is very important as it determines the stability of the aluminium paste and the shape of the particles.

After grinding, the aluminium paste is passed through a filtration system to remove possible impurities. Our quality control team will then carry out a series of tests on the product, such as particle size, gloss, metallic feel, etc., to confirm that the product meets our high quality standards.

Products that have passed rigorous testing are carefully packaged and then stored in our warehouses, ready for shipment to our customers.

Please note that this is a basic production process and the exact process may vary depending on the specific requirements of the product. At Five Star Materials, we take quality control very seriously and ensure that our products meet our strict quality standards at every step of the production process.

At Five Star Material, we understand that every project is unique, and our goal is to provide the best customized solutions for each customer.

We will contact you within 24 hours.

For your urgent inquiries,please contact us through whatsapp No. : +86-18001668319