Offset Printing has emerged as a cornerstone for producing high-quality and visually appealing printed materials in the dynamic realm of printing technology. As a leading player in the industry, Five Star New Materials is dedicated to exploring and advancing the materials that drive this process. Today, we delve into the fascinating world of aluminum paste used in offset printing, shedding light on its composition, features, application requirements, and its pivotal role in enhancing printing outcomes. For businesses and professionals seeking to elevate their printing standards, understanding the intricacies of aluminium paste in offset printing is not merely beneficial but essential. It can unlock new possibilities for creating stunning visual effects and meeting customers’ ever-growing demands in various sectors such as packaging, advertising, and industrial applications. So, join us as we embark on this informative journey to uncover the secrets behind aluminium paste in offset printing and how it can revolutionize your printing endeavours.

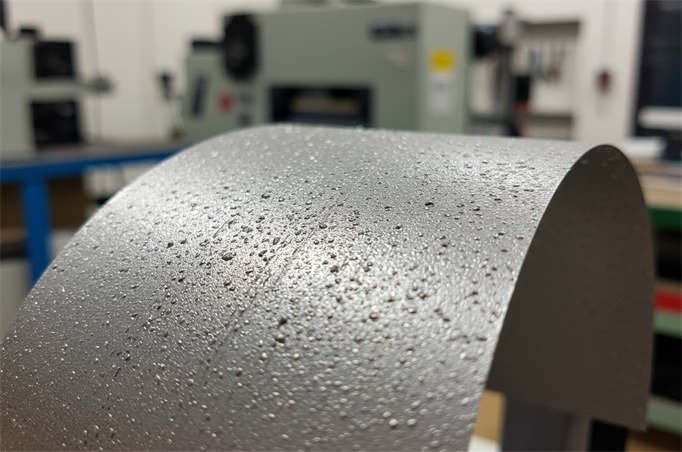

Offset Printing Aluminium Paste

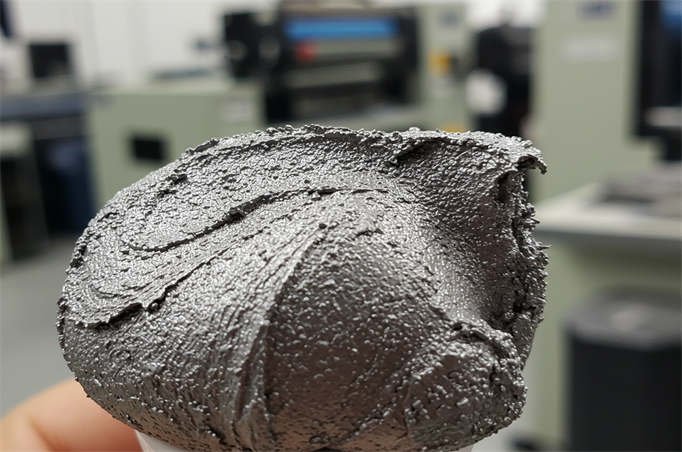

Our analysis indicates that offset printing ink aluminium paste primarily comprises aluminium powder, solvent oil, silicone oil, and additives.

Key Features We Observe:

- Strong Covering Power: This paste effectively covers the underlying layer, making printed materials’ metallic colours stand out more prominently and enhancing visual impact.

- Good Transferability: During the printing process, the aluminium paste transfers better from the carrier surface to the printing substrate, ensuring the clarity and integrity of the printed materials.

- Fast Drying Speed: It aligns with the fast printing characteristics of offset printing, enabling rapid drying and setting, which improves efficiency and does not affect subsequent printing processes.

- Good Ink Compatibility: The paste disperses easily in the ink and dissolves well with other components, forming a uniform and stable matching system that ensures stable printing performance.

- Good Water Resistance: After printing and drying, it exhibits good moisture resistance, preventing colour fading or falling off in humid environments or when exposed to water, thereby extending the service life of the print.

Process Standards We Understand:

- Particle Size Control: Aluminium paste used for offset printing typically has a particle size between 2-10μm. The narrower the particle size distribution, the better the ink’s spreadability and the greater the clarity and uniformity of the printed materials.

- Moisture Content Control: The lower the moisture content of the aluminium paste, the better. It should not exceed 0.2%. Otherwise, it can easily cause ink swelling and compromise printing quality.

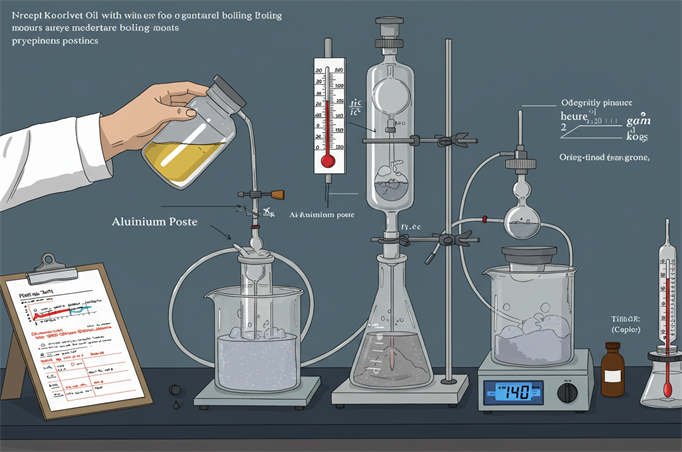

- Solvent Oil Selection: Generally, solvent oils with a moderate boiling point are chosen for cutting to avoid affecting ink performance and printing effects due to excessively high or low boiling points.

Application Areas We Recognize:

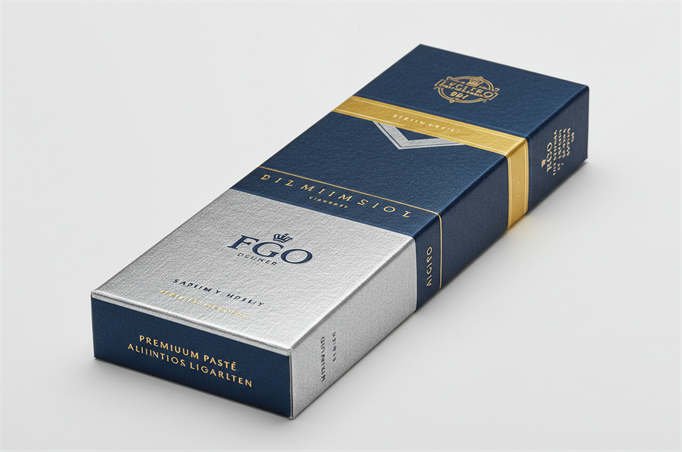

- High-End Packaging: Widely used in high-end packaging such as cigarette packs, wine labels, food packaging, and daily chemical product labels, it adds an elegant metallic lustre and enhances product grade and added value.

- Advertising Posters: It makes printed materials more exquisite and eye-catching, attracting consumer attention and helping to improve brand image and advertising effectiveness.

- Industrial Packaging: It provides packaging products with a sturdy and durable metallic texture while meeting environmental protection and sustainable development requirements.

Development Trends We Note:

With increasing environmental protection requirements, higher demands arise for the ecological performance of offset printing aluminium paste. Manufacturers must adopt environmentally friendly processes and raw materials to ensure the aluminium paste meets the required environmental standards, satisfying the market’s need for green printing.

Important Considerations for Aluminium Paste in Offset Printing:

During the offset printing process, the following aspects deserve careful attention when using aluminium paste:

Environmental Control:

- Temperature and Humidity: Aluminium paste is particularly sensitive to the temperature and humidity of the printing environment. Generally, a suitable printing operation temperature is 20℃-25℃ (68°F-77°F), and the air humidity is 40%-60%. If the temperature is too high, the aluminium paste will dry quickly, leading to plate clogging and poor transfer during printing. If the humidity is too high, the aluminium paste easily absorbs moisture, affecting the metallic lustre and printing effect.

- Cleanliness: Maintain a clean printing workshop to prevent dust and impurities from entering the aluminium paste, which can compromise printing quality and cause spots or defects on the printed surface.

Ink Preparation:

- Thorough Stirring: Stir the aluminium paste thoroughly before use to ensure a uniform and consistent state. The aluminium powder and other components in the aluminium paste may settle, and uneven stirring can lead to inconsistent colours in the printed materials, affecting their appearance.

- Effective Proportioning: According to the printing requirements and ink characteristics, reasonably allocate the mixing ratio of aluminium paste and ink. Generally, the amount of aluminium paste ranges from 5% to 30%, and the specific ratio must be determined through testing. Too little paste produces a poor metallic effect; conversely, too much can cause excessive ink viscosity and poor transfer.

- Operating Viscosity: Use a viscometer to measure the ink viscosity and adjust it appropriately based on printing speed, printing press performance, and other factors. Generally, the suitable viscosity for offset printing ink is 15- -25 (Ford Cup #4). If the viscosity is too high, add an appropriate amount of thinner to adjust it; if the viscosity is too low, appropriately increase the amount of aluminium paste and add a binder.

Printing Operation:

- Printing Speed: Strictly control the printing speed to match the drying speed of the aluminium paste. If the printing speed is too fast, the aluminium paste cannot achieve sufficient transfer and drying, leading to issues such as sticking and uneven colour on the printed surface. Too slow a printing speed may cause the aluminium paste to dry too quickly, affecting printing quality.

- Printing Pressure: Adjust the appropriate pressure to ensure the aluminium paste transfers evenly to the printing surface. Too little pressure will result in incomplete transfer and lighter printing colours; too much pressure may cause excessive squeezing of the aluminium paste, leading to uneven metallic texture and dot gain.

- Printing Maintenance: During the printing process, pay attention to maintaining the printing plate’s cleanliness and good ink receptivity. Handle ink deposits and impurities on the printing plate to avoid clogging or damage. Regularly check the wear of the printing plate and replace it when necessary to ensure printing quality.

Colour Control:

- Special Colour Management: The colour and gloss of aluminium paste may vary due to factors such as batch number and manufacturer. Select the appropriate aluminium paste according to the design requirements and implement special colour management during printing. If colour mixing printing is required, conduct a colour standard evaluation and printing accuracy adjustment in advance to ensure accurate and consistent colours.

- Density Detection: Densitometers and other testing tools are used to detect and control the colour density of the aluminium paste in the printed materials. According to the printing requirements and standard density values, adjust the ink dosage and printing parameters promptly to ensure that the colour density of the printed materials meets the specifications.

Production Process Monitoring:

- Equipment Inspection: Before printing, conduct a comprehensive inspection of the printing equipment to ensure its normal operation. Focus on checking the ink supply system, printing units, drying devices, and other parts to avoid compromising printing quality and production progress due to equipment failure.

- Quality Inspection: During printing, assign dedicated personnel to conduct quality inspections and promptly obtain printing samples for testing. The basic inspection includes quality standards such as metallic texture, color uniformity, dot reproduction, and solid ink density. Correct printing parameters or take corresponding solutions promptly.

- Consumables Management: Pay attention to using consumables such as ink, blankets, and plates during printing. Regularly check these consumables to avoid affecting the printing effect due to quality issues.

Post-Printing Processing and Storage:

- Drying and Solidification: Ensure that the printed materials are sufficiently dried and solidified. Select appropriate drying conditions and time according to the aluminium paste drying method (natural, hot air, UV, etc.). Improperly dried printed materials are prone to rubbing off and fading, affecting final product quality.

- Careful Handling: Be cautious when storing and transporting printed materials. Avoid external forces such as squeezing, impact, and friction to prevent damage to the printed materials. Prevent the printed materials from contact with water, oil, acid, alkali, and other substances to protect the aluminum paste coating on the printed surface.

- Storage Environment: Store unused aluminum paste properly in its original packaging and seal it tightly. The storage environment should be cool, dry, and ventilated, avoiding direct sunlight and high temperatures to prevent mould and agglomeration of the aluminium paste. Generally, the storage temperature of aluminum paste should be controlled between 5℃-30℃ (41°F-86°F), and the storage period should not be too long, preferably within 6 months to 1 year.

Safety and Environmental Protection:

- Operational Safety: Aluminium paste is flammable, so pay attention to operational safety during use. Prevent contact between the aluminium paste and fire, high-temperature heat sources, and ensure good ventilation in the printing workshop to prevent the accumulation of volatile organic compound (VOC) gases emitted by the aluminium paste, which can lead to fire or explosion accidents. Operators should wear protective equipment, such as masks, gloves, and goggles, when using aluminium paste to avoid contact with skin and eyes and to prevent human bodily harm.

- Environmental Treatment: Waste ink, waste solvents, wash water, and other wastes generated during printing should be classified and disposed of in accordance with environmental regulations and must not be discharged without authorization. Choose professional environmental treatment departments for recycling to avoid air pollution. At the same time, minimize the consumption of organic solvents during the printing process, fully promote environmentally friendly inks and cleaning fluids, reduce VOC emissions, and comply with environmental protection regulations.

The Impact of Aluminium Paste Particle Size on Offset Printing Effects:

The particle size of offset printing aluminium paste significantly affects the printing results, mainly in the following aspects:

Impact on Metallic Texture:

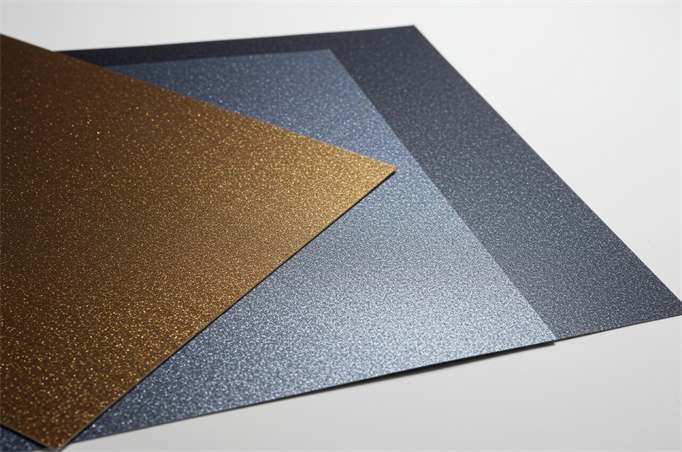

- Small Particles: Aluminium paste with small particles can arrange more closely on the printed surface after printing, reflecting light more uniformly. This makes the metallic texture finer and softer, appearing closer to the texture of real metal. It is suitable for high-end and exquisite metallic effects, such as the packaging printing of high-end cigarette cases and wine labels, which can enhance the product’s grade.

- Large Particles: Larger particles of aluminum paste arrange less densely, and the reflected light will have more scattering and diffuse reflection, resulting in a rougher and less smooth metallic texture, giving a visually prominent uneven effect. However, this effect can also serve as a unique design element in some prints that pursue a retro or industrial style, such as creative posters or industrial product packaging, creating a bold and raw atmosphere.

Impact on Printing Clarity:

- Small Particles: Small particles can better adapt to high-performance printing requirements, making printed pattern lines sharper and clearer. This effectively shows details such as small text and patterns, reducing jagged edges or blurring. It is suitable for printing fine and complex designs, such as circuit board patterns and intricate designs.

- Large Particles: During the printing process, large particles may accumulate in small gaps on the printing plate or along text edges, causing the edges of the printed lines to be less neat, and small patterns or text are prone to missing or deformation, reducing clarity. Printing content with high detail requirements, such as high-resolution images and fine text, will affect the final printing performance and readability.

Impact on Ink Rheology:

- Small Particles: Due to their small particle size and large specific surface area, small particles disperse more evenly in the ink and bond more closely with the ink, resulting in relatively better ink rheology. This means the ink flows, spreads, and transfers more easily during the printing process, better adapting to the high-speed operation of the printing press. It reduces printing problems caused by poor ink rheology, such as ink piling and stringing, and improves printing efficiency and stability.

- Large Particles: When particles are large and unevenly distributed, they can impair the rheological balance of the ink and reduce its fluidity. During printing, problems such as uneven ink transfer, partial accumulation, or ink starvation are likely to occur, affecting the continuity and consistency of the printing. This may lead to inaccurate registration and colour deviation, especially in colour mixing printing techniques.

Impact on Drying Performance:

- Small Particles: After printing with small particle aluminium paste, its larger specific surface area expands the contact area with the solvent in the ink, and the solvent evaporation rate is relatively faster. This promotes rapid drying and setting of the ink, reducing the risk of sticking and colour transfer to printed materials during drying. It improves work efficiency and integrates with the efficient production requirements of automated printing lines, which benefits some printing orders requiring quick delivery.

- Large Particles: Ink with large particle aluminium paste has a relatively slower drying speed because the solvent within the particles has a longer path to evaporate and is not easily released quickly. If post-processing or stacking is carried out urgently after printing, problems such as incomplete ink drying, sticking, and scratching may occur, compromising the quality of the printed materials. It is necessary to reasonably arrange the drying time in production or use auxiliary drying equipment.

Impact on Abrasion Resistance and Adhesion:

- Small Particles: The printing coating with small particle aluminium paste is denser and more uniform, with a larger contact area and stronger adhesion. This allows it to resist external friction and mechanical forces better, giving the print better abrasion resistance and durability. In daily use and transportation, it can maintain good metallic texture and pattern integrity, extending the service life of the print.

- Large Particles: The coating with large particles is relatively loose and easily falls off under friction or external force. The adhesion is relatively weak, and the abrasion resistance is reduced. For some printed materials that must be frequently touched or rubbed, such as packaging bags and labels, this may cause the metallic texture to disappear gradually and the patterns to become blurred, affecting the aesthetics and function of the printed materials.

As we conclude our exploration of aluminium paste in offset printing, Five Star New Materials reaffirms its commitment to providing top-notch materials and knowledge to the printing community. Proper use and understanding of aluminium paste can significantly elevate printed products’ quality and aesthetic appeal, opening doors to new market opportunities and customer satisfaction. In the competitive landscape of Offset Printing, attention to detail and the right choice of materials make all the difference. We encourage you to implement the insights this blog shares into your printing processes and continue pushing the boundaries of what’s achievable in the industry. Five Star New Materials stands ready to support your journey with our expertise and high-quality products. Let’s create a future where printed materials meet and exceed expectations, setting new benchmarks for excellence in Offset Printing and beyond.

We at Five New Materials trust that this detailed explanation sheds light on the significant role of aluminium paste in achieving exceptional results in Offset Printing. While our focus remains on providing superior aluminium paste for AAC block production, understanding this versatile material’s diverse applications and critical parameters across industries allows us to serve our customers better and appreciate its broader impact. For any inquiries regarding aluminium paste for AAC blocks, please do not hesitate to contact us!