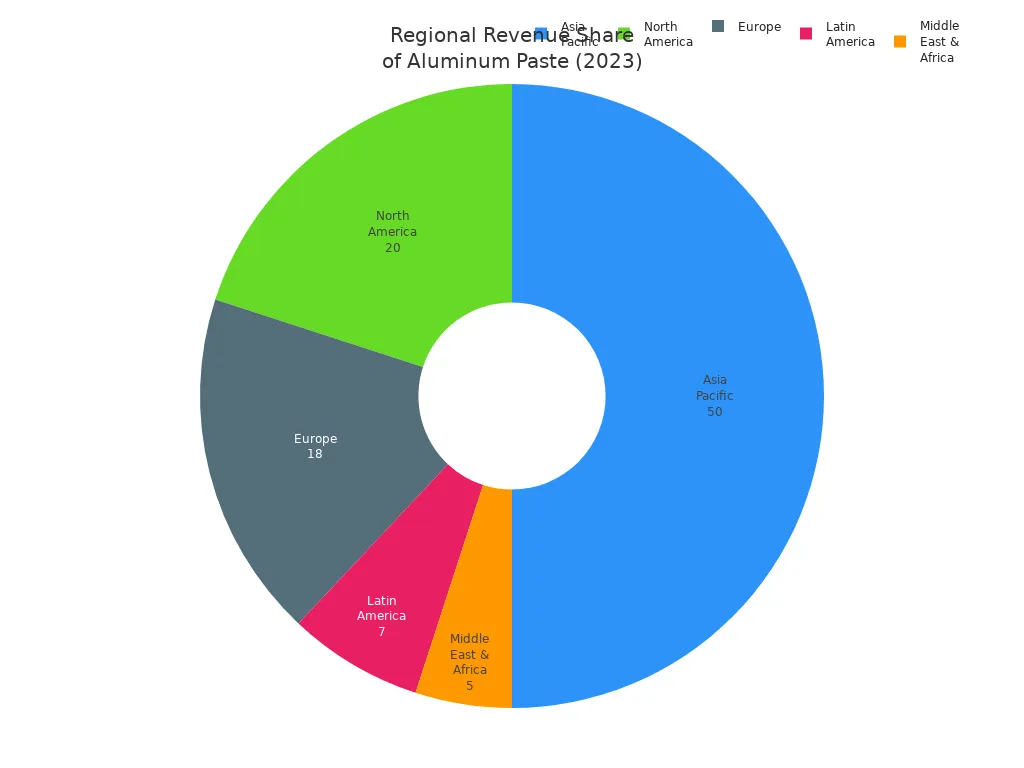

Choosing ALUALUMINUM PASTE FOR SOLAR CELLS can help your solar cells work better and lower costs. You should look at purity, particle size, viscosity, and if the paste fits your cell type. These things affect how well the electricity flows and if the materials work together. The world market for aluminum paste in solar cell making was 2.5 مليار دولار أمريكي في عام 2023، وحققت منطقة آسيا والمحيط الهادئ أكبر أرباح.

| الإحصاءات / القطاع | البيانات / القيمة |

|---|---|

| حجم السوق العالمية (2023) | 2.5 مليار دولار أمريكي |

| حصة الإيرادات في منطقة آسيا والمحيط الهادئ (2023) | ~50% |

| حصة السوق من التطبيقات | خلايا أحادية البلورة: 60% |

نصيحة: استخدم هذه الحقائق لتجنب الأخطاء الشائعة ومساعدة خلاياك الشمسية على العمل بأفضل أداء.

النقاط الرئيسية

- اختر معجون الألومنيوم الذي يناسب نوع الخلايا الشمسية الخاصة بك. تأكد من أنه يتوافق مع عملية الإنتاج الخاصة بك. فهذا يساعد الخلايا على العمل بشكل أفضل ويوفر المال.

- انظر إلى الخصائص المهمة للمادة اللاصقة مثل النقاء وحجم الجسيمات. تحقق أيضًا من اللزوجة ودرجة حرارة الحرق. هذه العوامل تساعد على تكوين اتصال كهربائي جيد. كما أنها تساعد على إطالة عمر الخلايا.

- جرب العجينة الجديدة في المختبر أولاً. اختبرها على خطوط إنتاج صغيرة قبل استخدامها في كل مكان. هذا يساعدك على اكتشاف المشاكل مبكراً. كما يساعدك على الحصول على نتائج أفضل.

- اعمل مع الموردين الذين تثق بهم. يجب أن يزودوك بلصق متماثل دائمًا. يجب أن يساعدوك في حل المشكلات الفنية. هذا يضمن سهولة واستقرار الإنتاج.

- لا ترتكب الأخطاء الشائعة. لا تنس التحقق من أن المعجون يتناسب مع خلاياك. لا تفكر في السعر فقط. لا تتجاهل مدى موثوقية المعجون. فهذا يحافظ على عمل خلاياك الشمسية بشكل جيد ويساعدك على كسب المزيد من المال.

المتطلبات

نوع الخلية

يجب أن تتوافق معجون الألومنيوم مع تقنية الخلايا الشمسية الخاصة بك. لكل نوع من الخلايا احتياجاته الخاصة:

- تستخدم الخلايا التقليدية، و PERC أحادية الوجه، و PERC ثنائية الوجه، و TOPCon، و HJT (الوصلات غير المتجانسة) معجون الألومنيوم، ولكن كل منها تحتاج إلى صيغة مختلفة.

- يجب أن يكون المعجون اللزوجة المناسبة، والالتصاق، والترطيب، والتشتت. تساعدك هذه الخصائص على طباعة المعجون بسلاسة وتجنب مشاكل مثل الانسداد أو الالتصاق.

- بالنسبة للخلايا PERC ثنائية الوجه، يتم وضع معجون الألومنيوم على الجانب الخلفي. يجب أن يعمل بشكل جيد مع معجون الفضة الموجود على الجانب الأمامي.

- تغير المواد الرابطة والمواد المضافة العضوية الموجودة في المعجون جودة الطباعة وكفاءة الخلية.

- يجب أن تختار معجونًا يتوافق مع فيلم التخميل الخلفي وعملية الحرق المشترك. وهذا يساعدك على الحصول على كفاءة أفضل وتكاليف أقل.

- يمكن لبعض المعاجين أن تحفر طبقة التخميل الخلفية وتكوّن نقاط تلامس محلية بين الألومنيوم والسيليكون. وهذا يعني أنك لا تحتاج إلى خطوة LCO منفصلة.

- يساعدك التحكم الجيد في المعجون على تجنب العيوب والحصول على أفضل عامل تعبئة وتخميل، خاصة عند الحواف.

نصيحة: تحقق دائمًا من أن المعجون مناسب لنوع الخلية والعملية. هذه الخطوة يمكن أن توفر لك الوقت والمال.

أهداف الكفاءة

تحدد أهداف الكفاءة الخاصة بك التفاصيل الفنية التي تحتاجها في معجون الألومنيوم. إذا كنت تريد كفاءة عالية، فيجب عليك التحكم في كثافة سطح المعجون ودرجة حرارة الحرق. على سبيل المثال، كثافة سطحية حوالي 3.52 ودرجة حرارة حرق قريبة من 840 درجة مئوية تحقيق أفضل النتائج. تساعدك هذه الإعدادات في الحصول على عامل تعبئة أعلى وعمر أطول للناقل. إذا استخدمت كمية كبيرة من المعجون، سينخفض عامل التعبئة. إذا استخدمت كمية قليلة جدًا، فقد لا تحصل على تلامس كافٍ. احرص دائمًا على تحقيق التوازن الصحيح للوصول إلى أهداف الكفاءة التي تريدها.

حجم الإنتاج

فكر في الكمية التي تخطط لإنتاجها. إذا كنت تدير مصنعًا كبيرًا، فأنت بحاجة إلى معجون يعمل جيدًا في الطباعة عالية السرعة ويقدم نفس النتائج في كل مرة. يتيح لك الإنتاج على نطاق صغير اختبار صيغ جديدة أو صنع خلايا مخصصة، ولكنك لا تزال بحاجة إلى معجون سهل الاستخدام ويقدم نتائج مستقرة. اختر معجون يتناسب مع احتياجات الإنتاج الخاصة بك حتى تتمكن من تجنب الهدر والحفاظ على سلاسة العملية.

معجون الألومنيوم للخلايا الشمسية: العوامل الرئيسية

النقاء

يجب عليك التحقق من درجة نقاء معجون الألومنيوم الخاص بك. النقاء العالي يعني وجود عناصر ضارة أقل بداخله. هذه العناصر الضارة يمكن أن تضر بكفاءة عمل الخلايا الشمسية. الشوائب يمكن أن تسبب مشاكل في طبقة التلامس الخلفية. وهذا يقلل من كمية الطاقة التي تنتجها الخلايا الشمسية. استخدام معجون الألومنيوم عالي النقاء للخلايا الشمسية يساعد على إطالة عمر الخلايا. كما يساعدها على العمل بشكل أفضل. تطبق الشركات الكبرى قواعد صارمة للحفاظ على مستويات الشوائب منخفضة. وهذا يتوافق مع أفضل الممارسات في صناعة الطاقة الشمسية.

حجم الجسيمات

حجم جزيئات الألومنيوم في المعجون مهم. تحتوي معظم أنواع المعجون على جزيئات يتراوح حجمها بين 1 و 80 ميكرومتر. يبلغ حجم الجزيئات الرئيسية في طبقة التلامس الخلفية حوالي 3-5 ميكرومتر. يساعد هذا الحجم على تحقيق التوازن بين القوة والتدفق الكهربائي. إذا كانت الجسيمات كبيرة جدًا، فقد تتشقق الخلايا أو تنحني عند تشغيلها. إذا كانت صغيرة جدًا، فقد لا تحصل على مجال خلفي جيد. وهذا قد يقلل من طاقة الخلية. اختر معجونًا بحجم جسيمات مناسب لتجنب هذه المشاكل. هذا يحافظ على قوة وكفاءة الخلايا الشمسية.

اللزوجة

تُظهر اللزوجة مدى سماكة أو رقة المعجون. فأنت تريد معجونًا ليس سائلًا جدًا ولا سميكًا جدًا. تتيح لك اللزوجة المناسبة طباعة خطوط ناعمة. كما تمنع الشاشة من الانسداد أو الفوضى. تساعد اللزوجة الجيدة على التصاق المعجون بالخلية. كما أنها تشكل طبقات متساوية. وهذا يجعل خلاياك الشمسية تبدو أفضل وتعمل بشكل أفضل. إذا كانت اللزوجة غير مناسبة، فقد تهدر المواد. كما قد تحصل على تلامس كهربائي ضعيف.

كثافة السطح

الكثافة السطحية تعني كمية الألومنيوم الموجودة على سطح الخلية. وهذا يؤثر على مدى جودة اتصال المعدن بالخلية. كما يؤثر على كمية الطاقة التي تحصل عليها. يمكن أن تؤدي زيادة كمية الألومنيوم إلى خفض مقاومة التلامس. وهذا يساعد على تحسين تدفق الكهرباء. ولكن زيادة كمية الألومنيوم بشكل مفرط يمكن أن تؤدي إلى حدوث ارتفاعات كبيرة. ويمكن أن تؤدي هذه الارتفاعات إلى إتلاف الخلية وخفض جهدها الكهربي. أما قلة كمية الألومنيوم فتعني أن التلامس قد لا يكون قوياً بما يكفي. لذا، عليك إيجاد التوازن المناسب.

| عامل كثافة السطح | التأثير على الخلايا الشمسية |

|---|---|

| محتوى أعلى من الألومنيوم | مقاومة تلامس أقل، تلامس أومي أفضل |

| الكثير من الألومنيوم | ارتفاعات كبيرة، مزيد من إعادة التركيب، جهد كهربائي أقل |

| زجاج جيد وقابلية للبلل | اتصال أفضل، كفاءة أعلى |

نصيحة: قم دائمًا بقياس كثافة السطح والتحكم فيها. فهذا يساعدك في الحصول على أفضل النتائج من معجون الألومنيوم للخلايا الشمسية.

درجة حرارة الحرق

يجب عليك تسخين العجينة على درجة الحرارة المناسبة. هذا يساعدك على الحصول على أفضل أداء. يقول معظم الخبراء حوالي 750 درجة مئوية هو الأفضل. إذا قمت بالتسخين عند درجة حرارة منخفضة، فإن مقاومة التلامس تظل عالية. ولا يتشكل المعدن بشكل جيد. إذا قمت بالتسخين عند درجة حرارة عالية جدًا، فقد تتلف الخلية. وهذا يزيد من إعادة الترابط ويقلل من الكفاءة. توفر درجة حرارة التسخين المناسبة تلامسًا قويًا. كما أنها تساعد على إطالة عمر الخلايا الشمسية.

| درجة حرارة الحرق (درجة مئوية) | النتيجة |

|---|---|

| أقل من 750 | مقاومة تلامس عالية، تلامس معدني ضعيف |

| حوالي 750 | أفضل توازن، اتصال قوي، كفاءة جيدة |

| أكثر من 750 | المزيد من الضرر، إعادة تركيب أعلى، كفاءة أقل |

الريولوجيا

الريولوجيا هي كيفية تدفق العجينة وانتشارها. تساعدك الريولوجيا الجيدة على طباعة خطوط دقيقة وطبقات متساوية. تريد أن تنتشر العجينة بما يكفي لملء الشاشة. لا ينبغي أن تنتشر في كل مكان. التصاق جيد، ترطيب، وتشتت كلها جزء من علم الريولوجيا. تساعدك هذه العوامل على استخدام كميات أقل من المواد وإنتاج خطوط أفضل. كما تحصل على كفاءة أعلى. إذا لم تبلل العجينة الشاشة أو الخلية جيدًا، فقد تظهر فجوات أو نقاط ضعف. إذا لم تنتشر الجزيئات بالتساوي، فقد لا تعمل الخلية بشكل جيد.

- الالتصاق الجيد يحافظ على بقاء المعجون على الخلية أثناء الطباعة والتحميص.

- يساعد الترطيب على تغطية المعجون لسطح الخلية دون ترك فجوات.

- يضمن التشتت انتشار الجزيئات بشكل متساوٍ. وهذا يساعد كل جزء من الخلية على العمل بنفس الطريقة.

جديد معجون الألومنيوم للخلايا الشمسية الاستخدامات جزيئات بحجم النانو ومواد مضافة جديدة. هذه المواد تحسن الخصائص الريولوجية. فهي تساعد على الحصول على موصلية أفضل وألواح شمسية تدوم لفترة أطول. تستخدم العديد من الشركات الآن تركيبات صديقة للبيئة. وهذا يجعل العملية أكثر أمانًا للعمال والبيئة.

ملاحظة: اتبع دائمًا قواعد السلامة عند استخدام معجون الألومنيوم. ارتدِ قفازات واعمل في مكان به هواء نقي. قم بتخزين المواد الكيميائية بأمان. تستخدم العديد من المصانع مذيبات وأساليب إعادة تدوير أكثر صداقة للبيئة. وهذا يساعد في حماية البيئة.

التوافق

توافق الركيزة

عليك أن تختار معجون الألومنيوم للخلايا الشمسية التي تناسب الركيزة الخاصة بك. كل ركيزة خلية شمسية، مثل السيليكون من النوع p أو النوع n، تحتاج إلى شيء خاص. إذا استخدمت معجونًا خاطئًا، فقد تفقد خليتك المزيد من الطاقة. وهذا يعني أن خليتك الشمسية لن تعمل بشكل جيد. بالنسبة للخلايا من النوع n، تحتاج إلى معجون لا يضر بطبقة التخميل. حجم فتحة التلامس المحلية (LCO) مهم أيضًا. التوافق الجيد يمنحك تلامسًا أوميًا قويًا ويحافظ على عمل خليتك بشكل جيد.

نصيحة: اقرأ دائمًا ملصق المعجون للتأكد من أنه يتوافق مع الركيزة قبل البدء في صنع الخلايا.

عملية التمعدن

الخاص بك عملية التمعدن يخبرك بكيفية وضع المعجون وإجراء الاتصالات. تحتاج إلى إجراء اتصال أومي جيد والحفاظ على انخفاض فقدان الطاقة. يمكن أن تتلف بعض أنواع المعجون طبقات التخميل، مثل AlOx أو SiNx، إذا لم تتحكم في العملية. بالنسبة لخلايا n-TOPCon، يمكن أن تتسبب معاجين الفضة والألومنيوم العادية في حدوث ارتفاعات تضر بطبقة التخميل. وهذا يؤدي إلى مزيد من فقدان الطاقة وانخفاض الكفاءة. تستخدم الطرق الأحدث، مثل LECO، معاجين خاصة خالية من الألومنيوم. لا تحفر هذه المعاجين إلا في الأماكن اللازمة، لذا تحصل على مقاومة تلامس أفضل وجهد دائرة مفتوحة أعلى. تحتاج خلايا التقاطع غير المتجانس (HJT) إلى معاجين تتصلب في درجات حرارة منخفضة. هذا يحافظ على سلامة الطبقات الرقيقة ومقاومة التلامس منخفضة. يحتاج كل نوع من الخلايا وعملية معينة إلى تركيبة معجون خاصة بها.

- اختر معجونًا يناسب تصميم خليتك.

- راقب درجة حرارة الحرق للحفاظ على سلامة طبقات التخميل.

- استخدم معاجين خاصة للخلايا المتطورة مثل HJT أو IBC.

ملاءمة إطلاق النار

يجب عليك التحقق مما إذا كانت المعجون الخاص بك يمكنه تحمل عملية الحرق. بعض أنواع المعجون تحتاج إلى حرارة عالية، بينما تعمل أنواع أخرى عند درجة حرارة أقل. إذا قمت بالحرق عند درجة حرارة غير مناسبة، فقد تتلف الخلية أو تصبح نقاط التلامس ضعيفة. بالنسبة للحرق الشامل، يجب أن يخترق المعجون طبقة التخميل بما يكفي لإجراء تلامس جيد، ولكن ليس بشكل مفرط بحيث يتسبب في تلف. قم دائمًا باختبار المعجون الخاص بك مع إعدادات الحرق حتى لا تحصل على نتائج سيئة.

| نوع الخلية | احتياجات الإطلاق | ميزة اللصق مطلوبة |

|---|---|---|

| PERC | إطلاق قياسي | التصاق جيد، تدفق مناسب |

| n-TOPCon | نافذة إطلاق دقيقة | ضرر منخفض، اتصال قوي |

| HJT | معالجة درجات الحرارة المنخفضة | رابطة قوية، مقاومة منخفضة |

ملاحظة: مطابقة المعجون مع عملية الحرق يساعد الخلايا الشمسية على العمل بشكل أفضل ويطيل من عمرها.

المورد والجودة

السمعة

من المهم اختيار مورد ذو سمعة طيبة. أنت تريد شركة تعمل في مجال الطاقة الشمسية منذ سنوات عديدة. تقدم شركة Five Star Materials معجون الألومنيوم للمصانع منذ أكثر من 15 عامًا. يثق الكثير من الناس في منتجاتها لأنها تعمل دائمًا بشكل جيد. على سبيل المثال، شركة كبيرة شركة الألواح الشمسية في كاليفورنيا جعلت خلاياها 2% أفضل بعد استخدام معجون Five Star Materials. يمكنك الاطلاع على التقييمات والجوائز والشهادات لمعرفة أفضل الموردين. غالبًا ما يعمل الموردون الجيدون مع أفضل المختبرات ويتبعون قواعد صارمة من مجموعات مثل اللجنة الكهروتقنية الدولية (IEC).

نصيحة: اختر موردًا له تاريخ قوي. فهذا يساعدك على تجنب المشاكل والحصول على نتائج أفضل.

الدعم الفني

تحتاج إلى أن يقدم لك المورد دعماً تقنياً جيداً. يساعدك الدعم الجيد على حل المشكلات بسرعة والحفاظ على استمرار عمل مصنعك. لدى Five Star Materials فرق في جميع أنحاء العالم لمساعدتك في الإعداد وحل المشكلات. يقوم خبراؤها بتعليم عمالك مهارات جديدة من خلال برامج مثل ISRA VISION Academy. يمكنك استخدام برامج خاصة مثل Connected Photovoltaics 4.0 للتحكم في الجودة على جميع خطوط الإنتاج. تتيح لك أداة الوصفات المركزية تغيير الإعدادات بسرعة. يعرض لك برنامج EPROMI live البيانات ولوحات المعلومات في الوقت الفعلي. وهذا يساعدك على اكتشاف المشكلات وحلها على الفور. هذه الأدوات تجعل عملك أسهل وتمنع التأخير. يمكنك تعديل عمليتك والحصول على أفضل النتائج من معجون الألومنيوم.

- تساعد فرق من جميع أنحاء العالم في الإعداد وحل المشكلات.

- التدريب يجعل موظفيك يتعلمون أشياء جديدة.

- يمنحك البرنامج التحكم ويساعدك على رؤية ما يحدث.

اتساق الدُفعات

اتساق الدفعة يعني أن كل شحنة من عجينة الألومنيوم يعمل بنفس الطريقة. تريد أن تكون كل دفعة بنفس درجة النقاء وحجم الجسيمات والسماكة. تقوم Five Star Materials بفحص كل دفعة باختبارات صارمة. تقوم مختبراتهم باختبار العينات قبل إرسالها للتأكد من أن العجينة مناسبة. لم يتوقف مصنع الخلايا الشمسية في تكساس عن العمل بعد التحول إلى Five Star Materials لأن دفعاته كانت دائمًا متماثلة. عندما تكون الدفعات متسقة، تتجنب الأخطاء وتعمل خلاياك الشمسية بشكل أفضل. يجب أن تطلب من موردك نتائج الاختبارات والشهادات. هذا يساعدك على معرفة أن معجونك سيعمل جيدًا في كل مرة.

| عامل الجودة | لماذا هذا مهم |

|---|---|

| النقاء | يضمن عمل الخلايا بشكل جيد |

| حجم الجسيمات | يوقف التشققات والمشاكل |

| اللزوجة | يساعدك على الطباعة بسلاسة |

| اتساق الدُفعات | يقلل من النفايات ويوقفها |

ملاحظة: اطلب دائمًا نتائج الاختبارات الدفعية من المورد. فهذا يحافظ على سلامة مصنعك ويساعدك على تحقيق أهدافك.

الاختبار

فحوصات المختبر

يجب أن تبدأ دائمًا باختبار الجديد عجينة الألومنيوم في المختبر. تساعدك الفحوصات المختبرية على معرفة ما إذا كان المعجون يلبي احتياجاتك الأساسية قبل استخدامه في مصنعك. يمكنك قياس اللزوجة وحجم الجسيمات والنقاء باستخدام أدوات بسيطة. يجب عليك أيضًا التحقق من كيفية طباعة المعجون على رقائق الاختبار. ابحث عن خطوط ناعمة وتغطية متساوية. استخدم مجهرًا لاكتشاف أي شقوق أو فجوات. يمكنك اختبار الالتصاق باستخدام اختبار الشريط اللاصق. اسحب الشريط اللاصق وانظر ما إذا كان المعجون لا يزال على الرقاقة. إذا لاحظت أي مشاكل، يمكنك إصلاحها قبل الانتقال إلى اختبارات أكبر.

نصيحة: توفر لك الفحوصات المخبرية الوقت والمال من خلال اكتشاف المشاكل في مرحلة مبكرة.

تجارب تجريبية

بعد إجراء الفحوصات المختبرية، يجب إجراء اختبارات تجريبية. تستخدم الاختبارات التجريبية أدوات إنتاج حقيقية ولكن على نطاق أصغر. تساعدك هذه الخطوة في اكتشاف المشكلات التي لا تظهر في المختبر. يمكنك استخدام خطوط تجريبية تعالج ما يصل إلى 100 رقاقة في الساعة. يمكن لبعض الخطوط معالجة ما يصل إلى 1400 رقاقة في الساعة. يمكنك تحسين كل أداة وخطوة عملية في ظل ظروف حقيقية. يجب أن تبحث عن مشاكل في الطباعة أو الحرق أو انتشار اللصق. يمكنك أيضًا إجراء تحليل الكسب والخسارة لمعرفة أين تفقد الطاقة أو الكفاءة. إذا وجدت مشكلة، يمكنك تغيير العملية والاختبار مرة أخرى. يساعدك هذا في الحصول على نتائج أفضل قبل البدء في الإنتاج بكميات كبيرة.

| الجانب | الوصف |

|---|---|

| دور الخطوط التجريبية | سد الفجوة بين المختبر والإنتاج الضخم |

| المعدات والقدرات | أدوات معالجة ما يصل إلى 100-1400 رقاقة/ساعة |

| تحسين العمليات | صقل كل خطوة في ظل ظروف حقيقية |

| تحليل الخسائر | ابحث عن المكان الذي تفقد فيه الطاقة أو الكفاءة |

| المسائل المادية | اكتشاف مشاكل في المعجون أثناء توسيع النطاق |

| التصنيع التكراري | اصنع عدة دفعات لتحسين النتائج |

| النتيجة | حل المشكلات وتعزيز الكفاءة (على سبيل المثال، ما يصل إلى 19.211 تيرابايت 3 تيرابايت في الجولة الثانية) |

مقاييس الأداء

تحتاج إلى قياس مدى جودة عمل العجينة. استخدم مقاييس واضحة للحكم على الأداء. تُظهر الكفاءة الكهربائية مقدار الطاقة التي تنتجها خليتك. يمكن أن يمنحك مجال السطح الخلفي القوي ما يصل إلى 0.11 تيرابايت 3 تيرابايت أكثر كفاءة. يخبرك انحناء الرقاقة ما إذا كان المعجون يحافظ على الرقائق الرقيقة من التشقق. يعمل المعجون الجيد حتى مع الرقائق الرقيقة التي يصل سمكها إلى 150 ميكرومتر. قوة الالتصاق هي المفتاح أيضًا. تريد أن يبقى المعجون على الرقاقة، حتى في الحرارة والرطوبة. يمكنك استخدام اختبار الشريط أو قياس قوة التقشير. ابحث عن قوة التصاق أعلى من 3 نيوتن/سم.

| مقياس الأداء | الوصف | الطريقة/القيمة |

|---|---|---|

| الكفاءة الكهربائية | اكتساب الطاقة من مجال السطح الخلفي القوي | ما يصل إلى 0.11 تيرابايت 3 تيرابايت تقريبًا |

| انحناء الرقاقة | يمنع التشققات في الرقائق الرقيقة | يعمل حتى سمك 150 ميكرومتر |

| قوة الالتصاق | يبقى اللصق على اللصق تحت الضغط | >أكثر من 3 نيوتن/سم؛ اختبار الشريط/ القشر |

ملاحظة: تتبع دائمًا هذه المقاييس للتأكد من أن عمليتك تمنحك أفضل النتائج.

الأخطاء التي يجب تجنبها

تجاهل التوافق

يجب أن تتحقق دائمًا مما إذا كان معجون الألومنيوم يناسب نوع خليتك الشمسية ومعالجتها. إذا تخطيت هذه الخطوة، فقد لا يلتصق المعجون جيدًا. كما يمكن أن يجعل الاتصال الكهربائي ضعيفًا. قد تفقد الخلايا الشمسية الخاصة بك الطاقة أو حتى تنكسر أثناء الإنتاج. على سبيل المثال، يعد استخدام معجون للخلايا من النوع p على الخلايا من النوع n مشكلة. يمكن أن يتسبب هذا الخطأ في المزيد من خسائر إعادة التركيب. ستحصل على طاقة أقل ومواد مهدرة. اقرأ دائمًا ملصق المنتج والأوراق الفنية قبل البدء. إذا لم تكن متأكدًا, اسأل المورد الخاص بك للمساعدة. التأكد من تطابق العجينة يساعدك على تجنب الأخطاء ويحافظ على تشغيل المصنع بشكل جيد.

نصيحة: جرّب دفعة صغيرة أولاً لمعرفة ما إذا كان المعجون يعمل مع تصميم خليتك.

إغفال التكلفة مقابل الأداء

عليك التفكير في كل من التكلفة والأداء عند اختيار معجون الألومنيوم. إذا اخترت أرخص معجون فقط، فقد تدفع المزيد من المال لاحقاً. يساعد معجون الألمنيوم الجيد خلاياك على العمل بشكل أفضل من خلال جعلها تعكس المزيد من الضوء وتوصيل الكهرباء بشكل جيد. كما أنه يساعد على إيقاف التآكل. تشير التقارير إلى أن عدم الموازنة بين التكلفة والجودة يمكن أن تجعل تكاليفك ترتفع ومنتجاتك أسوأ. خيارات اللصق السيئة تقلل من الكفاءة وتجعلك تنفق المزيد من المال. وهذا يضر بأرباحك بمرور الوقت. يجب عليك التحقق من الموردين ومقارنة المعاجين من حيث التكلفة والجودة ومدى كفاءتها. القيام بذلك يساعد عملك في مجال الخلايا الشمسية على البقاء قويًا لفترة طويلة.

| العامل | التأثير على الربحية |

|---|---|

| منخفضة التكلفة ومنخفضة الجودة | ارتفاع التكاليف وانخفاض الكفاءة |

| الاختيار المتوازن | أداء أفضل، ربح أكبر |

إهمال الموثوقية

الموثوقية مهمة في كل جزء من عملية تصنيع الخلايا الشمسية. إذا نسيت الموثوقية، فقد تحصل على المزيد من الأخطاء وعدد أقل من الخلايا الجيدة. يمكن أن يؤدي استخدام معجون سيئ إلى اختلاف كل دفعة، وبالتالي لن تعمل جميع الخلايا بنفس الطريقة. يجب أن تطلب من المورد نتائج الاختبارات والشهادات لكل دفعة. يمنحك المعجون الموثوق نتائج ثابتة وتوقفات أقل في الإنتاج. وهذا يساعدك على تحقيق أهدافك وتقديم منتجات جيدة لعملائك.

ملاحظة: استخدام معجون موثوق يساعدك على النجاح لفترة طويلة ويحافظ على سمعتك الطيبة.

يمكنك تحسين أداء الخلايا الشمسية عن طريق اختيار معجون الألومنيوم المناسب للخلايا الشمسية. انتبه دائمًا إلى درجة النقاء وحجم الجسيمات واللزوجة. تأكد من أن المعجون يتناسب مع نوع الخلية. اختبر المعجون في المختبر أولاً. جربه على خطوط الإنتاج التجريبية قبل البدء في الإنتاج على نطاق واسع. اعمل مع الموردين الذين تثق بهم. الموردون الجيدون يقدمون مساعدة فنية قوية ويرسلون شحنات متماثلة دائمًا. تحقق من عمليتك عن طريق:

- استخدام المذيبات للحصول على السماكة المناسبة والخطوط الناعمة

- ضبط مسافة الانفصال بشكل صحيح عند الطباعة على الشاشة

- تعديل محتوى المعدن للحصول على تلامس جيد

خذ الوقت الكافي لتفكر في الطريقة التي تختار بها المعجون الآن. حتى التغييرات الصغيرة يمكن أن تساعد الخلايا الشمسية على العمل بشكل أفضل وتدوم لفترة أطول.

الأسئلة الشائعة

ما هو معجون الألومنيوم للخلايا الشمسية؟

معجون الألومنيوم للخلايا الشمسية هو مادة خاصة. يستخدمه الناس لتوصيل الأسلاك الكهربائية بالخلايا الشمسية. يساعد هذا المعجون الخلايا الشمسية على العمل بشكل أفضل ولفترة أطول. يمكنك معرفة المزيد على موقع وزارة الطاقة الأمريكية.

هل يمكن استخدام معجون الألومنيوم في الخلايا الشمسية البيروفسكايتية؟

يمكنك استخدام معجون الألومنيوم للخلايا الشمسية البيروفسكايتية. يجب أن يتوافق المعجون مع الركيزة وعملية الحرق. استشر موردك دائمًا واقرأ الأوراق الفنية للتأكد من ملاءمته.

كيف تختبر معجون الألومنيوم للخلايا الشمسية المنزلية؟

تختبر معجون الألومنيوم للخلايا الشمسية المنزلية عن طريق طباعته على رقاقة عينة. اشعله عند درجة الحرارة المناسبة. قم بقياس كمية الكهرباء التي ينتجها. استخدم اختبار الشريط اللاصق لترى ما إذا كان المعجون يلتصق جيدًا.

لماذا يعتبر حجم الجسيمات مهمًا في معجون الألومنيوم المستخدم في الخلايا الشمسية والخلايا الكهروضوئية؟

يؤثر حجم الجسيمات على طريقة طباعة المعجون وقوة التلامس. تساعد الجسيمات الأصغر حجماً على تحسين تدفق الكهرباء. قد تتسبب الجسيمات الصغيرة جداً في حدوث تشققات. اختر الحجم المناسب لنوع الخلية الشمسية لديك.

أين يمكنك العثور على موردين موثوقين لمعجون الألومنيوم للخلايا الشمسية؟

يمكنك العثور على موردين جيدين من خلال الاطلاع على التقييمات والشهادات. تحقق من مجموعات مثل SEIA (رابطة صناعات الطاقة الشمسية). يوفر لك الموردون الموثوقون دفعات متماثلة دائمًا ويساعدونك في الدعم الفني.