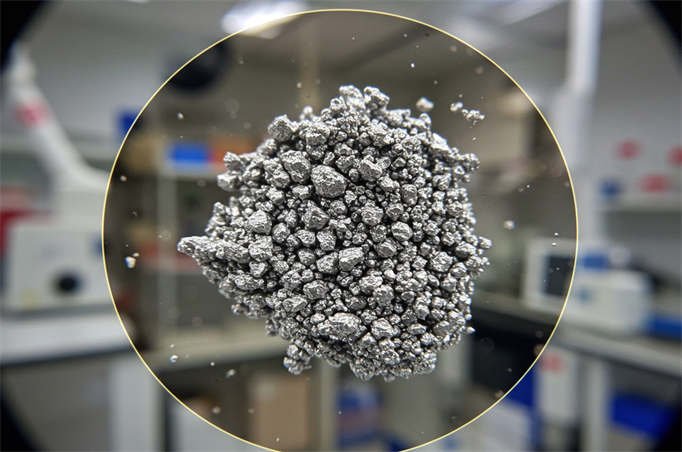

You use the aluminum paste leafing process to make a special metallic paste. This process gives a shiny and reflective finish. Tiny aluminum flakes float to the top when mixed into paint or coating. If you want products to look bright and like a mirror, aluminum paste leafing does that. You can see this special look in many decorative and protective finishes.

النقاط الرئيسية

- معجون الألومنيوم الورقي makes paint look shiny and like a mirror because it floats on top.

- The paste helps stop rust and keeps things safe from weather, so people use it outside.

- Wet ball milling and stearic acid coating are important steps to make the paste work well.

- Picking the right flake size changes how shiny and covered the finish will be.

- Leafing aluminum paste is put in cars, buildings, and packages because it looks bright.

What Is Leafing Aluminum Paste?

Definition and Key Features

Leafing aluminum paste is a special metallic pigment. When you add it to paint, the flakes float to the top. This happens because the flakes are coated with stearic acid. The coating helps them rise up in the paint. The top layer looks bright and shiny like a mirror. It reflects light and stands out.

Some important things about leafing pigments are:

- The flakes lay flat on the surface. This makes the coating look very shiny.

- You do not need much pigment to get a strong metallic look.

- The paste helps protect against water and weather.

- The finish is glossy and silver, so surfaces look clean and new.

نصيحة: If you want a coating that really shines, use leafing pigments.

Leafing vs. Non-Leafing Paste

You may wonder how leafing aluminum paste is different from others. The main difference is how the flakes act in the coating. Leafing pigments float to the top. Non-leafing pigments stay mixed in the whole layer.

Here is a simple table to show the differences:

| Type | التركيب | Performance Characteristics | التطبيقات |

|---|---|---|---|

| Leafing Aluminum | Coated with fatty acid, flakes float | Shiny, reflective, mirror-like finish | Automotive coatings, decorative finishes |

| Non-Leafing Aluminum | Treated to prevent floating, even dispersion | Good adhesion, better conductivity, less shine | Conductive coatings, adhesives, electronics |

You use leafing pigments for a bright, shiny look. Non-leafing types are better for strong sticking or electrical uses. Leafing aluminum paste gives a metallic effect that pops in coatings. You see these pigments in car paints, metallic inks, and anti-corrosion paints.

Aluminum Paste Leafing Process Steps

اختيار المواد الخام

You begin by picking pure atomized aluminum powder. The best powder is about 99.7% pure. Pure powder means fewer problems like cracks or spots. Companies use strict rules to choose the powder. This helps the aluminum paste work well in paints. Good raw materials make pigments that shine and last longer.

Wet Ball Milling

The next step is wet ball milling. This step turns powder into thin flakes. You put powder, steel balls, and solvent in a ball mill. The solvent keeps things cool and stops oxidation. Wet ball milling is safer than dry milling. You get a paste that is easy to move and use. Milling can take 2 to 15 hours. You control the speed to get the right flake size.

Wet ball milling makes the process safer. It also helps you make fine, flat flakes with a special shine.

Solvent Oil and Stearic Acid Addition

During milling, you add solvent oil and stearic acid. These help make the leafing effect. Stearic acid coats the aluminum flakes. This coating changes how flakes act in paint. Surface tension and leftover stearic acid help flakes float to the top. This creates a bright, mirror-like finish. Solvent oil stops flakes from sticking together. This makes the paste easy to mix and use.

Flake Formation and Coating

As milling goes on, flakes form and get coated with fatty acids. This coating makes leafing aluminum paste different. Flakes become thin and flat. The fatty acid layer helps flakes line up on the surface. When the coating dries, flakes stay on top. They make a shiny, metallic shield. This step is key for making pigments that reflect light and protect surfaces.

- Flakes line up to make a shiny layer.

- You get strong brightness and a smooth look.

- The coating helps protect against rust and weather.

Sieve Screening and Classification

After milling, you separate flakes by size. You use sieving and air classification. Sieving means passing paste through screens. Air classification uses air to sort flakes by size and weight.

| Method | الوصف |

|---|---|

| Sieving | Passes aluminum paste through sieves to ensure uniform particle size. |

| Air Classification | Uses air to separate flakes by size; smaller flakes travel farther. |

Uniform size is important for metallic pigments. Fine particles give a smooth finish. Bigger flakes make things brighter. If you do not sort flakes well, you may see spots or streaks.

Filter Pressing and Mixing

Now, you use a filter press to separate flakes from liquid. This step helps make good aluminum paste. After pressing, you mix the paste again. You use high-shear mixers. You control mixing time, speed, and temperature. This keeps every batch the same. You add stabilizers and other additives now. Companies follow strict mixing rules for quality.

Quality Control

Before shipping, you run many tests. You check raw materials for purity and size. You watch the process in real time. You check temperature, humidity, and mixing time. When finished, you test flow, gas release, and strength. You want a narrow size range, high shine, and good solvent mixing. Pure flakes and even spread help make the best pigments.

Safety tip: Always follow safety rules when making metallic pigments. Wear protective gear and handle solvents carefully.

By following these steps, you make sure your pigments shine, protect, and work well in paints, inks, and coatings.

Leafing Properties Factors

Particle Size and Shape

You can change how leafing pigments look by picking different flake sizes and shapes. Small flakes make the finish smooth and shiny like a mirror. Big flakes make the surface sparkle and cover more area. The table below shows how flake size changes how shiny and covering the pigment is:

| Particle Size Range | الانعكاسية | التغطية |

|---|---|---|

| 4–10 µm | High metallic luster, mirror effect | Good for spray coating, high floatation rate |

| 10–16 µm | Silvery-white sparkle, strong cover | Good for brush coating, moderate floatation rate |

| 7–13 µm | Eco-friendly, good for rough areas | Works for many uses, needs careful solvent control |

Pick the flake size that fits your project best. Use small flakes for a bright, shiny look. Medium flakes are good for rough surfaces. Flake shape is important too. Flat flakes bounce back more light and make things look brighter.

معالجة السطح

How you treat the surface of flakes changes how they act. When you coat flakes with fatty acids, it lowers surface tension. This helps flakes float to the top of the paint. You get a strong, shiny metallic look, almost like chrome. These pigments reflect light, UV rays, and heat. This keeps the surface under the paint safe from weather.

- You get a shiny layer that protects.

- The paint bounces sunlight and keeps things cooler.

- Sometimes, flakes can come off the paint. This makes it harder to repaint and can shorten how long the finish lasts.

Tip: Always check the surface treatment if you want your aluminum paste to last longer and shine brighter.

Making leafing pigments focuses on these things to give you the best results for decoration and protection.

Uses and Benefits of Leafing Aluminum Paste

Common Applications

Aluminum paste is used in many things. If you want a shiny look, you use leafing pigments. These pigments make surfaces bright and mirror-like. You find them in paints, inks, and coatings. They are used for cars, buildings, and packaging. The table below shows where metallic effect pigments are used:

| Application Type | الوصف |

|---|---|

| Automotive paints | Great for shiny, reflective finishes. |

| الأحبار | Makes packaging and labels look bright. |

| Anti-corrosion coatings | Protects steel from rust and damage. |

| Decorative finishes | Adds metallic effects to products and buildings. |

| أحبار الطباعة | Used for high-quality printing jobs. |

| مواد البناء | Makes things look good and protects them. |

| Specialty printing processes | Used for strong and shiny coatings. |

Aluminum paste leafing is used most in cars and buildings. These industries want surfaces that last and look nice. More people want coatings that are strong and shiny. This makes the market grow every year.

Why the Process Matters

Making aluminum paste does more than make things pretty. Leafing pigments create a metallic layer that blocks water and air. This layer keeps steel and other materials from rusting. Surfaces stay glossy and fade less, even after years. Metallic effect pigments reflect sunlight. This keeps things cooler in hot places. Buildings and machines last longer because of this.

Water-based aluminum paste helps the environment. New ways to make metallic effect pigments lower pollution and save energy. Companies now make pastes that follow strict rules and cost less. Using these products helps recycling and eco-friendly packaging.

Tip: Choose aluminum paste with strong leafing if you want coatings that shine, protect, and last.

You have learned how each part of the aluminum paste leafing process changes the final product. Each step, like picking pure aluminum, milling, and coating, helps make pigments that shine brightly. These pigments keep surfaces safe and make things look nicer.

- Leafing aluminum paste makes things look like a mirror.

- It stops rust and works well in tough weather.

- Water-based types are better for the environment.

- You should always use safety rules with these materials.

Knowing this process helps you choose well at work and at home.

الأسئلة الشائعة

What makes leafing aluminum paste different from non-leafing paste?

You see leafing aluminum paste float to the top of paint. This creates a shiny, mirror-like finish. Non-leafing paste stays mixed in the paint. It gives less shine and more even coverage.

Can you use leafing aluminum paste outdoors?

Yes, you can use it outside. The shiny layer reflects sunlight and helps protect surfaces from weather. You often see it on cars, buildings, and outdoor signs.

Is the production process safe?

You must follow safety rules during the production process. Wear gloves and masks. Handle solvents with care. Companies use special equipment to keep workers safe.

How do you store aluminum paste?

Store aluminum paste in a cool, dry place. Keep the container tightly closed. Avoid heat and open flames. This keeps the paste fresh and safe to use.

Why do you need to classify aluminum flakes by size?

Classifying flakes by size helps you get a smooth and even finish. Small flakes give a mirror effect. Large flakes make surfaces sparkle. Sorting ensures the best look for your project.