Aluminium Paste & Powder (APP) is a key aerating agent for producing lightweight aerated concrete. It reacts with alkaline substances to release hydrogen, creating a porous structure that enhances thermal insulation, soundproofing, and construction flexibility. Ideal for reducing building weight and improving earthquake resistance.

Aluminium Paste & Powder (APP) is a crucial aerating agent in producing AAC blocks. It reacts with alkaline substances to release hydrogen gas, forming a lightweight, porous structure. Below are the key aspects:

In an alkaline environment (e.g., Ca(OH)₂), Aluminium Paste & Powder reacts with water to produce hydrogen gas:

2آل+3Ca(OH)2+6H2O→3ثاني أكسيد الكالسيوم⋅آل2O3⋅6H2O+3H2↑

This reaction creates uniformly distributed pores within the slurry, reducing the final product density to 500-700 kg/m³—only one-fifth of conventional concrete.

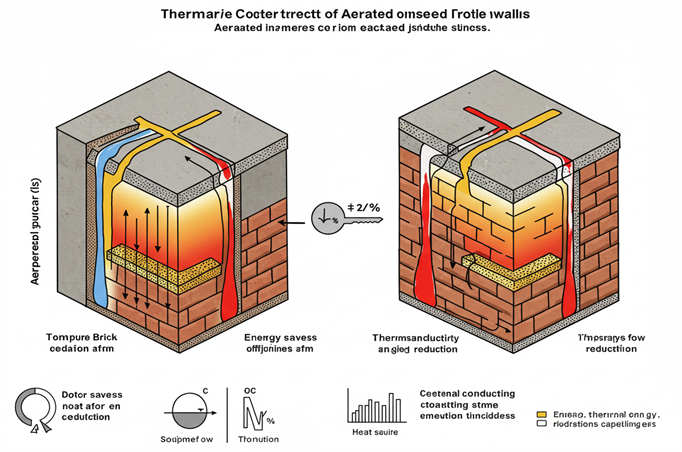

The size and distribution of pores directly determine AAC’s insulation and soundproofing properties. To achieve an ideal pore structure, the aluminum particles must have a suitable fineness (≤3% residue on a 0.075mm sieve) and a high active aluminum content (≥85%).

تُعد عملية إنتاج عجينة الألومنيوم الهوائية (الطين)/المسحوق الهوائي أمرًا بالغ الأهمية في تحديد جودة المنتج النهائي وأدائه. سيتناول هذا الفصل بالتفصيل تدفق الإنتاج والتقنيات الرئيسية ونقاط التحكم في كل مرحلة من مراحل عملية تصنيع عجينة الألومنيوم الهوائية (الطين)/المسحوق لمساعدة القراء على فهم أفضل لتصنيع هذه المادة الهامة.

يتضمن تدفق إنتاج عجينة الألومنيوم الهوائية (الطين)/المسحوق الهوائي عادةً الخطوات الرئيسية التالية:

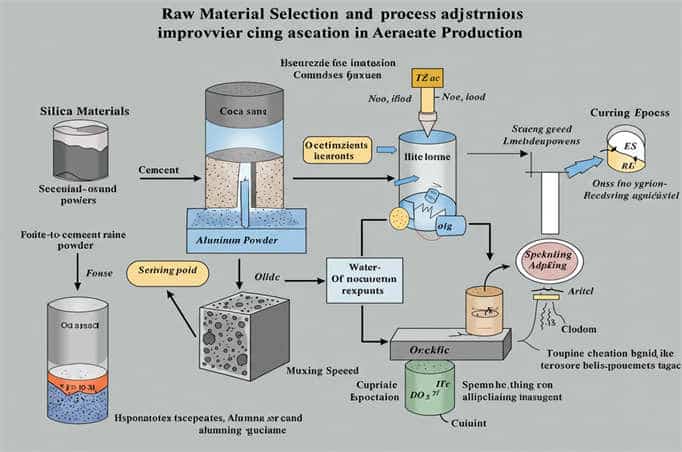

قبل بدء الإنتاج، يعد اختيار المواد الخام وإعدادها أمرًا بالغ الأهمية. إن الرئيسية تشمل المواد الخام مسحوق الألومنيوم والمواد المضافة (مثل ثنائي الفينيل متعدد الكلور ومشتتات الهواء، إلخ)، ومكونات أخرى. يعتمد اختيار مسحوق الألومنيوم عادةً على حجم جسيماته ونشاطه ونقاوته. يمكن لمسحوق الألومنيوم عالي النشاط أن يولد المزيد من غاز الهيدروجين عند التفاعل مع الماء، وبالتالي تحقيق تأثيرات أفضل لتوليد الغاز. يحتاج اختيار المواد المضافة إلى النظر في دورها في عجينة الألومنيوم الهوائية، مثل تحسين السيولة وتعزيز التفاعل.

يتم خلط مسحوق الألومنيوم المحضر والمواد المضافة في بعض التناسب. عادةً ما تستخدم هذه الخطوة معدات خلط عالية الكفاءة لضمان توزيع المكونات بشكل موحد وتجنب التكتل. يجب التحكم بصرامة في وقت الخلط وسرعته أثناء عملية الخلط لضمان مزيج كافٍ من مسحوق الألومنيوم والمواد المضافة، مما يضع أساسًا جيدًا للتفاعلات اللاحقة.

يجب طحن المواد المخلوطة للوصول إلى حجم الجسيمات المحدد. هذه الخطوة ضرورية لتحسين نشاط مسحوق الألومنيوم. يمكن أن يؤدي استخدام المطاحن الكروية أو أنواع أخرى من معدات الطحن إلى تقليل حجم الجسيمات بشكل فعال وزيادة مساحة سطح مسحوق الألومنيوم، وبالتالي تعزيز تفاعله مع الماء. بعد الطحن، يجب أيضًا تصنيف المواد لضمان اتساق حجم الجسيمات وتوزيع المنتج.

في هذه الخطوة، يتم خلط مسحوق الألومنيوم المطحون بالماء والإضافات الضرورية الأخرى لتشكيل عجينة الألومنيوم. يجب التحكم في ظروف التفاعل في هذا الوقت (مثل درجة الحرارة وسرعة التحريك) لضمان أن يكون التفاعل بين مسحوق الألومنيوم والماء كافٍ لتوليد بنية فقاعية مستقرة. يمكن الحصول على تأثير أفضل لتوليد الغاز والسيولة من خلال التناسب والتقليب المعقول.

يجب الانتباه إلى الظروف البيئية أثناء التخزين والنقل، وتجنب درجات الحرارة والرطوبة العالية والرطوبة العالية لمنع التفاعل المبكر والفشل. يجب فحص خصائصه الفيزيائية والكيميائية بانتظام أثناء التخزين لضمان استقرار جودة المنتج. وأخيرًا، يجب تعبئة عجينة الألومنيوم وفقًا للمعايير لضمان عدم حدوث أي تسرب أو تلف أثناء النقل.

في عملية إنتاج عجينة الألومنيوم الهوائية (الطين)/المسحوق الهوائي (الطين)/المسحوق الهوائي، هناك العديد من التقنيات الرئيسية التي لها تأثير عميق على أداء وجودة المنتج النهائي:

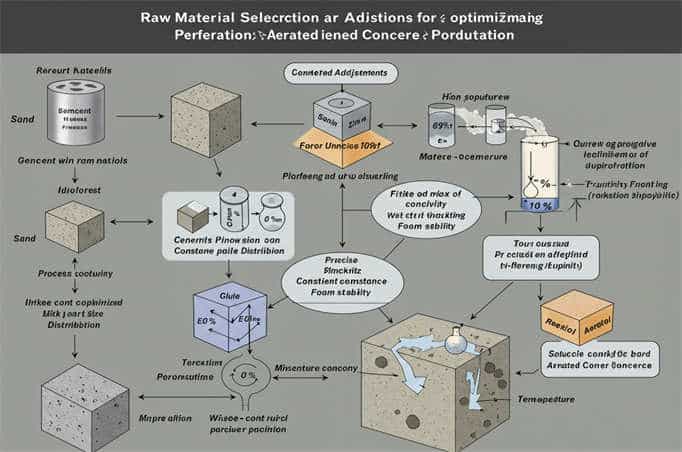

الطحن بالكرات هو مهم تكنولوجيا طحن مسحوق الألومنيوم. يمكن لعملية الطحن الفيزيائي أن تقلل بشكل فعال من حجم جسيمات مسحوق الألومنيوم وتزيد من مساحة سطحه المحددة. تساعد أحجام الجسيمات الأصغر على تعزيز تفاعلية مسحوق الألومنيوم، مما يسمح له بتوليد غاز الهيدروجين بسرعة أكبر عند التفاعل مع الماء، وبالتالي تشكيل بنية فقاعية موحدة ومستقرة.

تقنيات التصنيف تلعب دور مهمة دور في ضمان اتساق توزيع حجم الجسيمات لمسحوق الألومنيوم. من خلال التصنيف، يمكن فصل مساحيق الألومنيوم ذات أحجام الجسيمات المختلفة، مما يحسن من نشاط المادة وقدرتها على التكيف. يمكن أن يؤدي التوزيع المناسب لحجم الجسيمات إلى تحسين تكوين الفقاعات وتعزيز قوة الخرسانة الخلوية وأداء العزل الحراري.

في عملية تحضير عجينة الألومنيوم، يعد التحكم في ظروف التفاعل (مثل درجة الحرارة والوقت) أمرًا بالغ الأهمية. يمكن أن تضمن ظروف التفاعل المعقولة أن يكون التفاعل بين مسحوق الألومنيوم والماء كافٍ لتوليد عدد كافٍ من الفقاعات الموزعة بالتساوي. يساعد تطبيق تقنية التحكم في التفاعل على تحسين ثبات المنتج واتساقه.

يمكن تحسين أداء المنتج من خلال التحسين المستمر لصيغة عجينة الألومنيوم (الطين). على سبيل المثال، يمكن أن تؤدي إضافة كميات مناسبة من بعض المواد المضافة إلى زيادة معدل تفاعل مسحوق الألومنيوم وتحسين سيولة عجينة الألومنيوم وثباتها. بالإضافة إلى ذلك، بالنسبة لاحتياجات التطبيقات المختلفة، يمكن للشركات تطوير أنواع مختلفة من عجينة الألومنيوم لتلبية احتياجات السوق المتنوعة.

في الإنتاج، يعد التحكم في الظروف البيئية (مثل درجة الحرارة والرطوبة) أمرًا بالغ الأهمية أيضًا لضمان جودة المنتج. ومن الضروري توفير ظروف بيئية مناسبة خاصةً في مرحلتي التخزين والنقل، وذلك لمنع تعطل عجينة الألومنيوم أو تلفها بسبب التغيرات البيئية.

مراقبة الجودة هي مهم الارتباط طوال عملية الإنتاج لضمان الأداء المستقر لعجينة الألومنيوم الهوائية (الطين)/المسحوق. عادة ما تنشئ الشركات نظامًا كاملاً لإدارة الجودة، بما في ذلك:

قبل البدء في الإنتاج، يجب أن تخضع جميع المواد الخام لفحص صارم للجودة للتأكد من أنها تفي بمعايير الإنتاج. يجب اختبار نشاط مسحوق الألومنيوم ونقاوته وتوزيع حجم الجسيمات لتحديد ما إذا كان يفي بمتطلبات الإنتاج أم لا.

أثناء عملية الإنتاج، تتم مراقبة معلمات كل مرحلة (مثل درجة الحرارة والرطوبة ووقت الخلط وما إلى ذلك) في الوقت الفعلي لضمان أن تكون عملية الإنتاج في أفضل حالة دائمًا. وبالإضافة إلى ذلك، يمكن لمعدات الاختبار عبر الإنترنت اكتشاف المشاكل وتعديلها في الوقت المناسب لمنع توليد منتجات غير مؤهلة.

بعد إنتاج المنتج، يلزم إجراء اختبار أداء شامل للمنتج النهائي، بما في ذلك مؤشرات مثل السيولة وتوليد الغازات وقوة الضغط، لضمان استيفائه للمعايير ذات الصلة واحتياجات العملاء. يمكن فقط طرح المنتجات التي اجتازت الاختبارات الصارمة في السوق للبيع.

| Characteristic | Aluminum Paste (Water-based) | Dry Aluminum Powder |

|---|---|---|

| عملية الإنتاج | Wet grinding, no need for degreasing | Dry grinding, requires degreasing |

| السلامة | No dust explosion risk | Flammable and explosive, requires nitrogen protection |

| سهولة الاستخدام | Directly added to slurry, good dispersion | Requires pre-degreasing treatment |

| التأثير البيئي | Low pollution, easy wastewater treatment | High energy consumption, more pollution |

Below are key testing methods and technical requirements based on industry standards and practical applications:

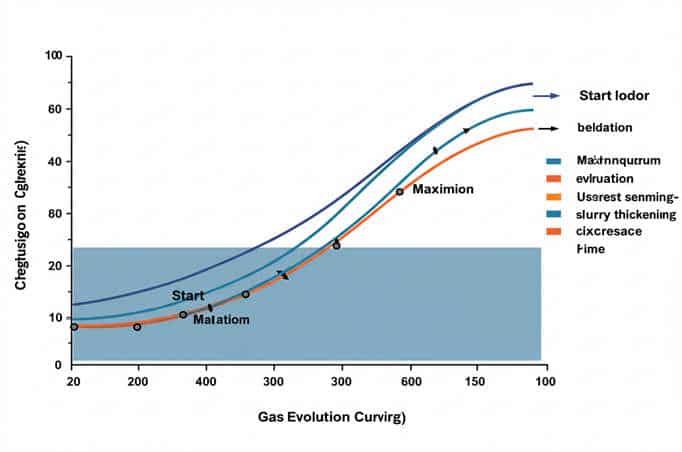

Aluminium Paste & Powder must aerate at a rate that aligns with slurry thickening:

Maintain slurry temperature at 40-60°C. Excessive heat accelerates aeration, risking uncontrolled expansion, while low temperatures slow aeration, leading to uneven pore distribution.

Fiver Star New Materials ensures optimal concrete quality, enhancing thermal efficiency, mechanical strength, and construction adaptability by fine-tuning aeration parameters.

| اسم المنتج | المحتوى الصلب (%) | الألومينا النشطة (%) | الكثافة السائبة | متوسط حجم الجسيمات (D₅₀) | مناسب لـ AAC |

|---|---|---|---|---|---|

| DEG-60 | 70% | ≥96 | 0.15 | 58-62 | <600 |

| DEG-40 | 70% | ≥94 | 0.15 | 36-42 | <500 |

| DEG-35 | 70% | ≥94 | 0.15 | 33-35 | <400 |

| DEG-25 | 70% | ≥94 | 0.15 | 25-27 | <400 |

| DEG-18 | 70% | ≥92 | 0.11 | 17-19 | <350 |

نقترح عليك أن تتواصل معنا بشكل كامل قبل الشراء، وسننظر بالتأكيد في جميع الجوانب ونقدم لك خطة أسعار عادلة ومعقولة. باختيارك لنا، ستحصل على أفضل منتج وأفضل قيمة مقابل نقودك.

يمنحك اختيار الحجم المناسب للمنتج أفضل قيمة مقابل المال. يتوفر معجون الألومنيوم الفضي المعدني فلاش الفضي لدينا في مجموعة كبيرة من أحجام الجسيمات ودرجة النقاء، وتختلف الأسعار حسب المواصفات. من خلال التواصل مع احتياجاتك بالتفصيل واختيار الحجم المناسب، يمكنك الحصول على أفضل قيمة مقابل نقودك.

كلما زادت الكمية المشتراة، انخفض سعر الوحدة. تسمح لنا الطلبيات بالجملة بتقاسم تكاليف الإنتاج والتشغيل بشكل أفضل، لذلك يسعدنا تقديم أسعار مخفضة للمشتريات بالجملة.

سيؤثر توقيت وطريقة الدفع التي تختارها أيضاً على السعر. على سبيل المثال، يمكن أن يؤدي الدفع مقدماً بالكامل إلى الحصول على سعر أفضل، لأنه يقلل من تكلفة رأس المال. يُرجى مناقشة خيار الدفع الأنسب مع فريق المبيعات لدينا.

كما أن النقل والخدمات اللوجستية من العوامل التي تؤثر على التكلفة الإجمالية للملكية. فوسائط النقل والوجهات المختلفة تترتب عليها تكاليف شحن مختلفة. يجب أيضًا أخذ الرسوم والتأمين والتكاليف الأخرى في الاعتبار. من خلال حساب هذه العوامل قبل الشراء، يمكنك تقدير التكلفة الإجمالية بدقة أكبر.

At Five Star Materials, our Aluminium Paste & Powder for AAC produced in a delicate and rigorous process. Below is our basic production process:

نشتري المواد الخام عالية النقاء من موردين موثوق بهم لضمان جودة منتجاتنا من المصدر.

يتم سحق المادة الخام لتحويل كتل الألومنيوم إلى جزيئات صغيرة للمعالجة اللاحقة.

يتم خلط مسحوق الألومنيوم المسحوق مع مذيباتنا وموادنا المضافة المصممة خصيصًا ثم يتم مزجها من خلال عملية خلط عالية السرعة. هذه الخطوة مهمة للغاية لأنها تحدد ثبات عجينة الألومنيوم وشكل الجسيمات.

بعد الطحن، يتم تمرير عجينة الألومنيوم من خلال نظام ترشيح لإزالة الشوائب المحتملة. يقوم فريق مراقبة الجودة لدينا بعد ذلك بإجراء سلسلة من الاختبارات على المنتج، مثل حجم الجسيمات واللمعان والملمس المعدني وما إلى ذلك، للتأكد من أن المنتج يفي بمعايير الجودة العالية لدينا.

المنتجات التي اجتازت الاختبارات الصارمة يتم تغليفها بعناية ثم تخزينها في مستودعاتنا لتكون جاهزة للشحن إلى عملائنا.

يُرجى ملاحظة أن هذه عملية إنتاج أساسية وقد تختلف العملية الدقيقة حسب المتطلبات المحددة للمنتج. نحن في فايف ستار ماتيريالز نأخذ مراقبة الجودة على محمل الجد ونضمن أن منتجاتنا تلبي معايير الجودة الصارمة الخاصة بنا في كل خطوة من خطوات عملية الإنتاج.

ندرك في شركة فايف ستار ماتيريال أن كل مشروع فريد من نوعه، وهدفنا هو تقديم أفضل الحلول المخصصة لكل عميل.

سنتصل بك خلال 24 ساعة.

لاستفساراتك العاجلة، يرجى الاتصال بنا عبر رقم الواتساب: +86-18001668319