You can see big changes in how solar cells are made today. Aluminum paste is very important for high-efficiency technologies like PERC. The world market for aluminum paste is growing fast. New technology helps solar cells work better and makes solar energy cheaper. Better formulas and nano-aluminum particles help solar cells work by making them conduct electricity and trap light better. Top manufacturers have high quality rules. This pushes research and development to meet the need for better solar power systems.

النقاط الرئيسية

- Aluminum paste is very important for solar cells. It helps the cells work better by making a strong back surface field. This lets the cells collect more electricity from sunlight.

- New types of aluminum paste use tiny particles. These new pastes work better and cost less. This makes solar energy cheaper for people.

- Making aluminum paste in a green way is important. Companies use better methods and materials to help the environment.

- Picking good aluminum paste from trusted companies is smart. It helps solar panels last longer and work better. Good brands spend money on research to improve their products.

- The solar energy market is growing fast. New ideas in aluminum paste help meet the need for better and cheaper solar power.

Aluminum Paste in PV Manufacturing

ما هو معجون الألومنيوم؟

Solar cells need special materials to work well. عجينة الألومنيوم is very important for this. It helps make a strong back surface field, called BSF, on the solar cell. This layer lets the cell collect more electricity from sunlight. The paste also sticks well to the silicon wafer. If you use good عجينة الألومنيوم, your solar panels work better and make more energy. Many companies, like Five Star Aluminium Paste, make sure their products are reliable for these jobs.

نصيحة: A strong back surface field helps your solar cell turn more sunlight into energy you can use.

Manufacturing Process Overview

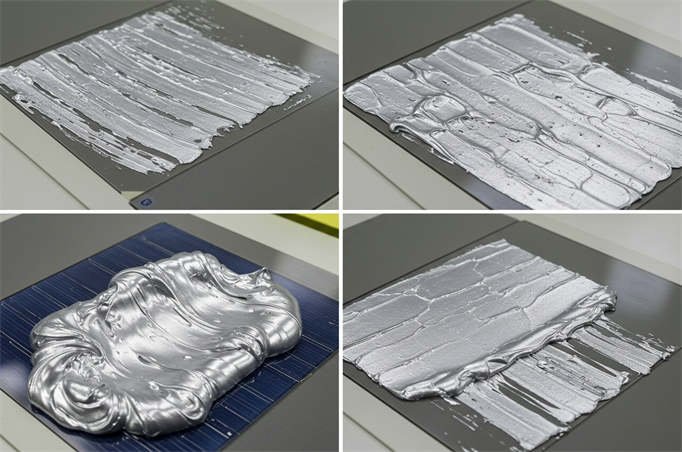

عجينة الألومنيوم is used in two main steps when making solar cells. These steps are screen printing and annealing. Here is what happens:

- You put عجينة الألومنيوم on the back of the solar cell with screen printing. This makes the rear electrode.

- The paste forms a thick layer, about 30 micrometers. This layer helps make the aluminum back surface field.

- In the firing step, the cell gets very hot, over 570 degrees Celsius. The aluminum and silicon mix together and make a special area that collects electric charges.

- When the cell cools down, the silicon turns into crystals again. How much aluminum is in the paste and how hot the cell gets changes how the crystals grow.

This process helps solar cells work better and last longer. That is why companies care about the quality of عجينة الألومنيوم. If you pick a trusted brand, your solar panels will work well for a long time.

Aluminum Paste Trends

High-Efficiency Cell Applications

Solar cell technology is changing fast. Companies use new cell types like PERC, TOPCon, and HJT. These cells work better and make more energy. معجون الألومنيوم is very important for these cells. New paste formulas help these cells work well and cost less. Ultra-fine-line screen printing uses less silver but keeps good conductivity. Lead-free glass frits in the paste help meet rules and bond better with silicon. If you use N-type HJT cells, low-temperature curing pastes protect thin layers and keep the cells working well.

| Trend Description | Implication for Solar Cell Technologies |

|---|---|

| Innovations in paste formulations | Enhances efficiency and reduces costs in PERC, TOPCon, HJT |

| Ultra-fine-line screen printing | Minimizes silver use, maintains conductivity |

| Lead-free glass frits | Meets regulations, improves silicon-contact formation |

| Low-temperature curing for HJT | Protects amorphous silicon layers |

| High-conductivity aluminum pastes | Improves back surface field (BSF) formation |

| Copper-based paste exploration | Offers cost-effective alternatives to silver |

ملاحظة: Five Star Aluminium Paste gives you reliable results for high-efficiency solar cells.

Advances in Paste Formulation

معجون الألومنيوم keeps getting better. New formulas help solar cells collect more electricity and last longer. The paste makes a stronger back surface field (BSF) in P-type silicon cells. This means solar cells lose less energy and work better. More companies use mono-crystalline silicon cells. These cells need special metallization pastes. These pastes make strong, conductive links on advanced wafer structures. You get higher efficiency with these new formulas.

- Pastes are made for mono-crystalline silicon cells.

- These pastes create strong, conductive links for better performance.

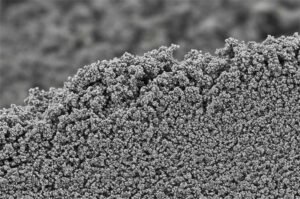

- Nano-sized aluminum particles in the paste help boost efficiency and lower costs.

Sustainability Initiatives

More companies care about the environment now. معجون الألومنيوم production follows stricter rules. Manufacturers make greener paste formulas to protect nature. They try to lower harm during production. Advanced technology like AI helps make paste with less waste. Companies also use materials from sustainable sources. This supports global carbon reduction goals.

| Initiative Type | الوصف |

|---|---|

| Regulatory Shifts | Clean energy adoption and stricter environmental standards |

| Greener Paste Formulations | More environmentally friendly formulas |

| Reduction of Environmental Impact | Efforts to minimize ecological footprint |

| Advanced Technologies | AI-driven monitoring and predictive analytics for efficiency |

| Material Sourcing | Sustainable sourcing to support carbon reduction |

Environmental rules make you use pastes without harmful chemicals. Government policies help you use safer practices. The industry moves toward products that avoid dangerous substances.

Cost Reduction Approaches

Solar energy needs to be affordable. Companies use معجون الألومنيوم instead of expensive silver paste. This saves money. UV pulse lasers remove layers in TOPCon cells and make the process cheaper. معجون الألومنيوم with different silicon content also lowers costs. New formulas and nano-sized particles help increase efficiency and cut expenses. Eco-friendly materials and better methods give higher yields and lower costs.

- You replace costly silver paste with screen-printed aluminum paste.

- You use UV pulse lasers for cheaper processing.

- You apply aluminum paste with varying silicon content to cut costs.

- You choose innovative formulas and nano-sized particles for better results.

- You pick green materials to meet demand for eco-friendly products.

- You benefit from advanced manufacturing for higher yields and lower costs.

| Evidence Type | الوصف |

|---|---|

| Market Growth | The global PV metallization aluminum paste market grows from $2.1B (2023) to $3.5B (2032). |

| Demand for Renewable | Solar power adoption and better PV cell efficiency drive demand for superior pastes. |

| Technological Advancements | Bifacial cells and PERC technology need specialized pastes for efficiency and cost savings. |

نصيحة: Five Star Aluminium Paste helps you get high-performance, cost-effective, and sustainable solutions for solar projects.

Top Manufacturers

Leading Global Producers

Many companies make Aluminum Paste for solar cells. These companies give you good and strong materials for your PV projects. Here are some of the top companies in the world:

- DuPont

- Heraeus

- تويو ألومنيوم

- معجون الألومنيوم فايف ستار

- Rutech

- Giga Solar

- Monocrystal

- Hoyi Tech

- Tehsun

- Kaiyuan Minsheng

- Leed

- ThinTech Materials

Five Star Aluminium Paste is known for its quality and new ideas. You can count on its products for advanced solar cells. Most of these companies make paste for high-efficiency cells. They also spend money on research to make their products better.

Innovation and Market Position

Top companies try to be the best by making new technology and following strict rules. Their new ideas help solar cells work better and last longer. The table below shows some new things they have done:

| Manufacturer | Innovation Description |

|---|---|

| تويو ألومنيوم | Changes particle size, surface, and uses new ways to mix. Also tries to use less energy. |

| Altana AG | Makes binders work better and helps pastes last in bad weather and with chemicals. |

| أساهي كاسي | Makes new materials for better color, safety, and stability. |

| Silberline | Makes aluminum paste with special surfaces for better use outside. |

Companies like Five Star Aluminium Paste and DuPont make water-based products to help the environment. You see new ways to treat surfaces and make pastes last longer, so solar cells work well even in hard places. Companies use AI and machine learning to watch how they make paste and improve their recipes. This gives you good quality and lower prices.

These companies follow world safety rules like REACH and use green methods. They make pastes for special cell types like PERC and heterojunction. They also try to use less material. You get pastes that stop thin wafers from bending, keep blisters away, and work with silver-aluminum systems. All these things help you build better solar panels and support clean energy.

Challenges and Opportunities

Supply Chain and Quality Control

Working with aluminum paste in solar cell manufacturing is not easy. The supply chain can change fast. Aluminum prices go up and down a lot. This happens because of global demand, energy costs, and problems in shipping. Sometimes, prices rise by 30%. High-purity aluminum is needed for solar cells to work well. It can be almost half of your production costs. If supply chains from places like China or Russia slow down, you pay more and wait longer for materials.

You also need to think about the carbon footprint. Making aluminum uses lots of energy. Many companies want to lower emissions and use greener ways. New rules and carbon pricing make costs go up. You must find more suppliers to avoid shortages.

نصيحة: Picking a trusted brand like Five Star Aluminium Paste helps you avoid risks and get good products.

Quality control is very important for strong solar cells. You want to find defects early. Advanced testing and in-house checks help you spot problems before customers get the panels. Some companies, like JA Solar, test every cell with special tools. They use electroluminescence tests to find hidden issues. These steps help your solar panels last longer and work better.

- Aluminum market changes quickly

- High carbon footprint from making aluminum

- Need to lower carbon in the supply chain

- Find more suppliers for safety

- Costs go up because of carbon pricing

- Catch defects early with quality control

- Use advanced testing for reliable products

| Evidence Type | الوصف |

|---|---|

| Trade Tariffs | Tariffs on imports can make things cost more and change how companies compete. |

| Import Regulations | Rules can limit supply and change how the market works. |

| Competitive Landscape Impact | Trade policies affect both producers and buyers in the market. |

Future R&D Directions

There are many new chances in research and development for aluminum paste. Companies now work on eco-friendly formulas and high-purity pastes. Brands like Hefei Sunrise and Toyo Aluminium K.K. lead with big manufacturing. There is more demand for sustainable coatings and high-performance pigments. These help solar cells work better and last longer.

You also see new ways to make aluminum paste fit special cell designs, like bifacial and PERC cells. Advanced coating methods help solar panels perform better. Artificial intelligence helps make better paste formulas and improve manufacturing. You can make pastes with lower emissions to meet green goals.

| Opportunity Type | الوصف |

|---|---|

| Environmentally Friendly Pastes | Making low-emission aluminum pastes to meet green goals. |

| Customization for Cell Architectures | More need for pastes made for special technologies like bifacial and PERC. |

| Advanced Coating Techniques | Using new coating methods to make PV modules work better. |

| AI in Formulation Optimization | Using artificial intelligence to make better paste and improve how it is made. |

🌱 You help the planet by picking aluminum paste with eco-friendly formulas. Five Star Aluminium Paste supports your clean energy and high performance goals.

Solar cell manufacturing is changing a lot. New Aluminum Paste helps solar cells work better and cost less.

- New formulas use tiny nano-aluminum particles and less metal. This saves money and makes cells more efficient.

- Special pastes fit different cell types. They help cells turn more sunlight into energy.

| Why Quality Matters | الوصف |

|---|---|

| Energy Conversion | Aluminum paste helps solar cells make power from sunlight. |

| Industry Demand | More solar panels means more paste is needed. |

| Usage | Many countries use a lot of paste for solar cells. |

| Quality | High-purity paste makes cells strong and smooth. |

There are problems like changing prices, new technology, and rules. Top brands like Five Star Aluminium Paste spend money on research and green solutions. You will see more new ideas and growth soon.

الأسئلة الشائعة

What does aluminum paste do in solar cells?

Aluminum paste makes the back contact on solar cells. It helps collect electricity from sunlight. This makes the cell work better.

Can you use aluminum paste for all solar cell types?

You can use aluminum paste for most silicon-based cells. It works for PERC, TOPCon, and HJT cells. Each type might need a special formula.

How does aluminum paste help lower costs?

Aluminum paste is cheaper than silver paste. You save money by using it for the back contact. This helps make solar panels less expensive.

هل معجون الألومنيوم آمن للبيئة؟

Manufacturers now use fewer harmful chemicals in aluminum paste. You can pick eco-friendly options that meet safety rules.

How do you check the quality of aluminum paste?

You test aluminum paste for purity and how well it conducts electricity. Trusted brands check their products and give certifications. This helps you get good results.