Aluminum paste msds papers help people see dangers and use the right safety steps. Every product may have different risks, so reading the right paper stops accidents. Safety and following rules depend on knowing what is inside and how it acts.

Always read the right safety data sheet before using any aluminum paste.

النقاط الرئيسية

- Always read the aluminum paste MSDS before you use it. This helps you know about risks and safety steps. Different aluminum pastes have their own chemical makeups. These can change how safe or useful they are. Use the right personal protective equipment like masks and gloves. This keeps you safe from health problems. Store aluminum paste in a cool and dry place. Keep it away from sunlight and things that can catch fire. Look at the MSDS for what to do in emergencies. This helps if there are spills or accidents.

Aluminum Paste MSDS: What Is Different?

Chemical Composition Variations

Aluminum paste comes in many kinds. Each kind has its own mix of aluminum flakes, solvents, and sometimes additives. The aluminum paste msds from each company lists these things. Some pastes have tiny flakes. Others have bigger flakes. The solvent can be mineral oil, water, or another liquid. These things change how the aluminum paste works. For example, Five Star Aluminium Paste uses a special mix that makes it less dusty. This helps lower the chance of breathing in particles. Always look at the sds for the exact mix. Even small changes in the recipe can change safety and how well it works.

Hazard and Fire Risk Differences

Not all aluminum paste products are equally dangerous. The aluminum paste msds will show if a product can catch fire or explode more easily. Some pastes react with water or acids and make hydrogen gas. This gas can catch fire quickly. The sds from different companies may warn about different dangers. Five Star Aluminium Paste, for example, talks about its low-dust mix, which can lower fire risk. The table below shows common dangers found in aluminum paste msds:

| Risk Type | الوصف |

|---|---|

| Flammability | All aluminum paste can catch fire easily. |

| Dust Inhalation Risks | Some sds warn about breathing in dust. |

| Neurotoxicity | Others talk about neurotoxicity, which can hurt memory and focus. |

| Chemical Reactions | Some pastes can make hydrogen gas if they touch water or acids. |

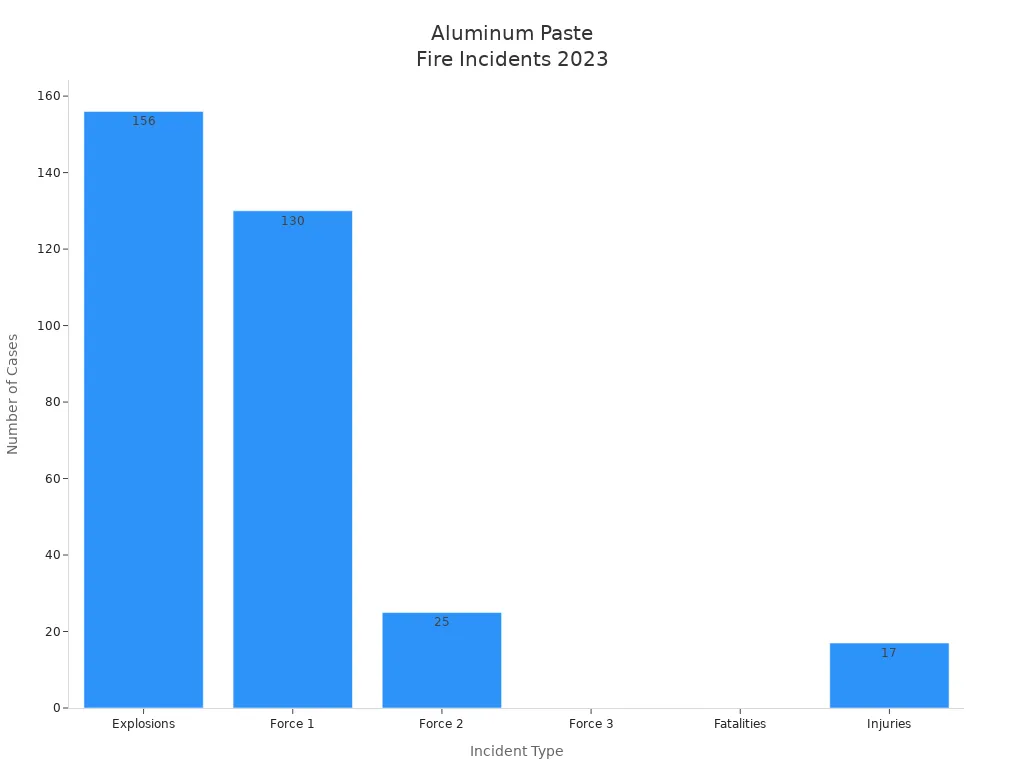

Fires and explosions happen every year. The chart below shows how many explosions and injuries happened in 2023 when people handled aluminum paste:

The sds for each aluminum paste will tell you the danger level. Some products need more care than others. Always read the aluminum paste msds before you use it.

Health Risks and PPE Protection

Aluminum paste can hurt your health if you do not use it right. The aluminum paste msds lists health risks and the personal protective equipment (PPE) you need. Some sds warn about breathing in aluminum flakes or solvent fumes. Others talk about skin or eye irritation. The table below compares safety needs for aluminum paste and other metal pastes:

| Safety Aspect | Aluminum Paste Specifics | Other Metal Pastes (e.g., Thermal Pastes) |

|---|---|---|

| Respiratory Protection | NIOSH-certified respirators (N95 or PAPR) are needed because of the risk of breathing in aluminum flakes and solvents. | Special respiratory protection is usually not needed. |

| Skin Contact | Protective clothes are needed to stop dry skin, irritation, and rare allergies. Wash right away if you touch it. | Skin irritation and protective clothes are less important. |

| Eye Protection | Safety glasses or goggles with indirect ventilation are needed to stop splashes and flying particles. | Eye protection is usually not listed. |

Some brands, like Five Star Aluminium Paste, may ask for extra PPE if their product has more solvent. Always follow the sds for the right PPE. Never guess what protection you need.

Handling, Storage, and SDS Instructions

Safe handling and storage keep aluminum paste from causing problems. The aluminum paste msds gives clear steps for this. Most sds say:

- Store aluminum paste in a cool, dry place.

- Keep it away from sunlight and things that can catch fire.

- Seal containers tight to keep out air and water.

Other tips from the sds include:

- Do not make dust clouds when pouring or mixing.

- Keep aluminum paste away from oxidizers and acids.

- Use only tools and equipment that do not make sparks.

Five Star Aluminium Paste sds says to reseal containers right after use. This keeps the product safe and fresh. Always check the aluminum paste msds for special steps. Each product can have its own storage or handling needs.

Note: Always check the sds for the exact aluminum paste you use. Never think all aluminum paste products have the same dangers or safety steps.

Safety Considerations When Using Aluminum Paste

Workplace Safety and Compliance

It is important to know what each aluminum paste MSDS says. Each MSDS lists dangers and safety steps. These details help workers stay safe. Rules about hazardous materials are strict in many places. The RoHS Directive limits dangerous substances in products. The PAHs Directive controls bad chemicals. EFSA rules make sure aluminum paste does not get into food. In China, GB 9685-2016 and GB 4806.10-2016 set rules for additives and harmful substances. Companies must follow these rules to keep workers safe. They also avoid fines by following the rules. Workers must check every MSDS to see if the aluminum paste is safe and follows all rules.

Fire and Explosion Prevention

Fire and explosion risks are very serious with aluminum paste. Some types can catch fire or explode if used wrong. The MSDS will show if the paste reacts with water or acids. Workers must store aluminum paste in cool, dry places. They must keep it away from sunlight and things that can spark. Good fire safety means using tools that do not make sparks. It also means sealing containers tight. Some aluminum paste does not have benzene or ketone. This lowers the risk of bad fumes. Low-odor and no solvent residue features help keep the workplace safe. Workers must always follow the MSDS for each product to stop accidents.

Health Protection and Exposure Controls

Health protection is very important when using aluminum paste. The MSDS tells workers what protective gear they need. Masks like N95 or powered respirators help stop breathing in flakes or fumes. Gloves and special clothes protect skin from irritation. Safety goggles keep eyes safe from splashes. Some aluminum paste can handle high heat. This means it will not release bad stuff when cooking. Workers must wash hands after using aluminum paste. They should never eat or drink near it. They must always use the right mask and follow all safety steps in the MSDS.

Evaluating SDS for Aluminum Paste

Key SDS Sections to Review

Safety data sheets help people learn about aluminum paste. Each sds has important parts to check. The hazard identification part lists dangers like fire or health risks. The composition section shows what chemicals are in the paste. Handling and storage instructions tell how to keep aluminum paste safe. The exposure controls and PPE section says what gear you need. The physical and chemical properties section tells how aluminum paste looks and acts. The fire-fighting measures section gives steps for emergencies. Reading these parts helps people know about different types of aluminum paste and their properties. Always look at the sds for storage and handling details.

Checklist for Reviewing SDS:

- Hazard identification

- Chemical composition and types

- Handling and storage instructions

- PPE and exposure controls

- Physical and chemical properties

- Emergency and fire-fighting steps

Questions for Suppliers

When picking aluminum paste, buyers should ask suppliers about the sds. Good questions to ask are:

- What are the main properties of aluminum paste in this product?

- Which types of aluminum paste do you have for different uses?

- How do you make sure each batch is the same?

- Can you explain the handling and storage rules for your aluminum paste?

- Do you give up-to-date safety data sheets and certificates?

- What are the main types of aluminum paste you sell?

Clear answers help buyers know about properties and storage needs. They also show if the supplier understands hazard identification and safe handling.

Red Flags and Best Practices

Some warning signs show a supplier may not follow safety or quality rules:

- Deliveries are late or missed a lot

- Pigment quality changes from batch to batch

- Slow answers or poor communication

- No current certificates or missing rule papers

- Prices go up for no reason or have hidden costs

- Not much technical help or no custom products

Tip: Always check the sds for missing or unclear information about properties, hazard identification, or handling and storage. If the sds does not list all types or uses of aluminum paste, ask the supplier for more details.

Best practices include keeping all safety data sheets updated and checking the properties of each batch. Store aluminum paste as the sds says. Follow all handling and storage steps to keep workers safe and protect the properties of the product.

Knowing the differences in aluminum paste MSDS helps workers stay safe. Each aluminum paste has its own risks and safety steps. The table below shows what to look for in every aluminum paste MSDS.

| ميزة | الوصف |

|---|---|

| Chemical Composition | Lists main ingredients, so users know what is inside. |

| توزيع حجم الجسيمات | Shows flake sizes, which change how you use it and how safe it is. |

| Hazard Identification | Tells about fire risks and health dangers, which is important for following rules. |

| Handling and Storage | Gives steps for safe storage and use, which helps keep workers safe. |

| Exposure Controls | Lists ways to control dust and fumes, which helps make work safer. |

| Emergency Procedures | Tells what to do for spills, fires, or chemical contact, which helps in emergencies. |

People sometimes make mistakes with aluminum paste. They may forget about chemical reactivity or not check hazards well. The table below shows some incidents that prove safety is important.

| Incident Description | Chemical Reactivity Concern | النتيجة |

|---|---|---|

| Explosion at Napp Technologies | Aluminum paste mixed with water | Fire and explosion |

| Abnormal blending conditions | Not knowing chemical dangers | Bad emergency response |

| Water-reactive substances present | Reactions kept going | Explosion because warnings were missed |

| Poor hazard analysis | Hot reactions at low temperatures | Not removing water caused accidents |

Always read the SDS for each aluminum paste before you use it. Ask suppliers for clear safety information. Use this checklist to stay safe:

- Check what is inside and the flake size

- Look at fire risks and emergency steps

- Follow storage, handling, and dust controls

Being careful keeps workers safe and helps follow the rules for aluminum paste.

الأسئلة الشائعة

What is the main difference between aluminum paste and other metal pastes?

Aluminum paste has aluminum flakes and special liquids. Other metal pastes use other metals. Aluminum paste can catch fire faster. The MSDS for aluminum paste lists special risks and safety steps.

Why does each aluminum paste MSDS look different?

Each company makes aluminum paste with its own recipe. The MSDS shows what is different. Some aluminum paste has more solvent or smaller flakes. Always check the MSDS for your aluminum paste.

What PPE should workers use with aluminum paste?

Workers need masks, gloves, and goggles for aluminum paste. The MSDS for aluminum paste tells what protection is needed. Some aluminum paste needs extra PPE if it has more solvent or dust.

How should aluminum paste be stored safely?

Store aluminum paste in a cool, dry spot. Keep it away from sunlight and things that can burn. The MSDS for aluminum paste gives storage rules. Seal containers tight to keep out air and water.

What should workers do if aluminum paste spills?

If aluminum paste spills, workers should follow MSDS steps. They should wear PPE, clean up the paste, and keep it away from water. Aluminum paste can react with water and make dangerous gas.