You can have many problems when making smooth powder finishes with pigment aluminium. Many makers see that flakes do not always line up right. This happens a lot in high-solids or waterborne coatings. You also have to think about rules for the environment. This makes it harder to get a perfect metallic look. Using the right pigment and getting your surface ready helps you stop these problems. If you focus on details and use trusted products like Five Star Aluminium Paste, your finish will look great.

النقاط الرئيسية

- Pick non-leafing pigment aluminium for a tough, shiny look. It spreads easily and sticks well. This helps the coating last longer.

- Clean and degrease your surface very well. Doing this can help powder stick better by 30%. It stops problems like peeling or bubbling.

- Mix pigment aluminium slowly so it does not clump. Add the right things to keep the metallic look smooth and even.

- Watch your curing heat and time closely. Set your oven to 160°C for 10 minutes. This gives you a strong, shiny finish that stays.

- Be gentle when you touch and store coated parts. Clean them often and keep them safe from bad weather. This keeps the finish looking new and stops damage.

Pigment aluminium selection

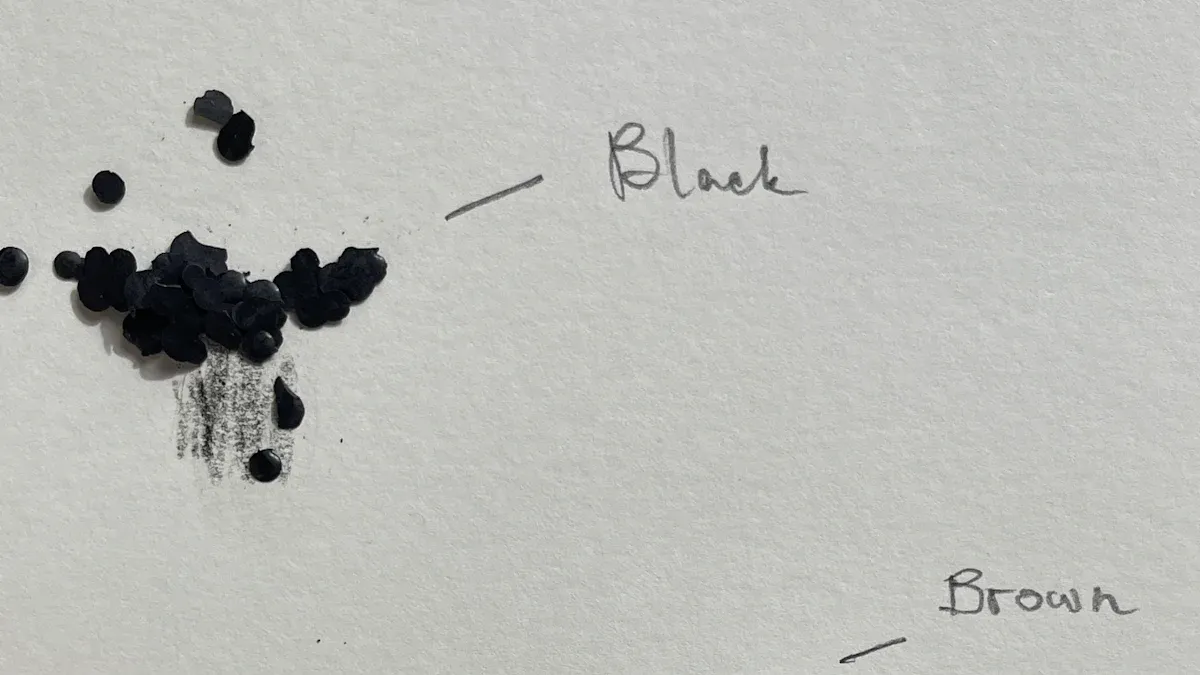

Non-leafing vs. pelletized pigments

When you pick pigment aluminium for powder coatings, you should know about non-leafing and pelletized pigments. Non-leafing pigments spread out well in the coating. They make the finish sparkle and stick better. This helps your finish stay nice and last longer. Leafing pigments make the surface shiny, but they do not stick as well. Flakes can fall off or lose shine after some time. Non-leafing pigments let you add more layers if you want a thicker finish.

Non-leafing pigment aluminium:

- Spreads out well

- Sparkles

- Sticks better

- Easy to add layers

Leafing pigment aluminium:

- Shiny look

- Does not stick well

- Flakes can fall off

If you want your powder coating to work well and look good, non-leafing pigment aluminium is the best choice for most jobs.

Choosing the right grade

Picking the right grade of pigment aluminium changes how your powder finish looks and lasts. Good grades give a strong metallic look. They also protect your surface from water and air, which stops rust. Many companies use metallic powder coatings with aluminium pigments because they look nice and last a long time. More people want these coatings every year.

Tip: Five Star Aluminium Paste helps you get the same results each time. It makes your finish bright and protects well, so it is great for both inside and outside projects.

| الفائدة | الوصف |

|---|---|

| Visual Appeal | Makes the finish shiny and pretty |

| مقاومة التآكل | Blocks water and air from hurting the surface |

| التأثير البيئي | Cuts down on VOCs and saves on repairs |

You help the planet when you choose stable pigment aluminium. These pigments lower VOCs and make your coating last longer, so you do not need to fix or change it often.

Surface preparation

Getting the surface ready is very important. It helps you get the best results with pigment aluminium in powder coatings. If you skip steps or hurry, the finish might peel or bubble. It could also flake off. You want your coating to last and look smooth. So, you must clean, degrease, and use primer the right way.

Cleaning and degreasing

Always start by cleaning the aluminum part. Dirt, grease, and old paint can stop powder from sticking. Removing these things gives your coating a strong base. Here are some key steps:

- Take off old dirt or paint before adding powder.

- Clean the surface with water, brushes, or special chemicals.

- Use degreasers and etching chemicals to remove oil and grease.

- Make sure there are no oxide layers or protective coatings left.

- Sandblasting or chemical treatments can make the surface rougher for better grip.

Cleaning and degreasing well can help powder stick almost 30% better. This means your finish will not peel or bubble as easily. You do not want flaking or the coating coming off, so do not skip this step. Five Star Aluminium Paste works best on a clean surface. It gives you a bright and even finish.

Sandblasting and primer use

Sandblasting is not always needed. But it can help your coating stick better and last longer. It makes the aluminum rough so powder can grip it. After cleaning, you might use a primer to stop rust, especially if your project will be outside.

| Evidence Description | النقاط الرئيسية |

|---|---|

| Sandblasting Effectiveness | Sandblasting helps powder stick and stops rust, even if not always needed. |

| RUSTOP® System Benefits | RUSTOP® gives strong grip and rust protection with easy prep. |

| Non-Zinc Primer الأداء | Non-zinc primers stop rust and stick better than zinc ones. |

You should choose a non-zinc primer for long-lasting protection. Non-zinc primers work well with pigment aluminium. They help your finish last, even in hard weather. This step keeps your project looking nice and safe from rust.

Mixing and dispersion

Incorporating pigment aluminium

You want your powder coating to look smooth and shiny. The way you mix pigment aluminium makes a big difference. If you use the right steps, you get even color and sparkle. If you rush or use the wrong method, you see dull spots or clumps.

You can use two main ways to add pigment aluminium to your powder coating:

- Dry-blend process: Mix the effect pigments and powder coating gently. This keeps the flakes whole and shiny.

- Bonding process: Heat the powder until it gets a little sticky. Then, bond the pigment aluminium to the powder particles. This method helps the pigment stick better and gives a more even finish.

You should always use gentle mixing. Too much force can break the flakes and ruin the metallic look. You can add a flow agent or dispersant additive. These help the pigment spread out and stop clumping. Five Star Aluminium Paste works well with both dry-blend and bonding methods. It gives you a bright, even finish every time.

Tip: Use gentle mixing and the right additives to keep your metallic effect strong and smooth.

Preventing agglomeration

Agglomeration means the pigment aluminium clumps together. This makes your finish rough and uneven. You want to stop this from happening. The way you mix and the type of particles you use matter a lot.

Mixing speed and time play a big role. If you stir at about 1,000 RPM for 10 minutes, you get a uniform mix. Finer particles mix faster and stay suspended longer. Coarser particles settle quickly, so you need to watch them closely.

Here are some things that can cause agglomeration:

- Incompatible solvent or resin systems can make the paste unstable.

- Wrong mixing methods, like not enough shear or too much force, can break flakes or leave them under-mixed.

- Additive or pH problems can make flakes swell and clump together.

You can prevent agglomeration by following these steps:

- Choose resin and solvent systems that work well with your pigment aluminium.

- Use the right mixing steps to protect the flakes.

- Store your mixture properly and check the formula to stop sedimentation.

The table below shows how mixing speed and time affect dispersion quality:

| Mixing Speed (RPM) | Mixing Time (min) | Dispersion Quality |

|---|---|---|

| 500 | 5 | Poor |

| 1,000 | 10 | Excellent |

| 1,500 | 15 | Good |

You get the best results when you use the right speed and time. The Taguchi method shows that mixing time and agitation speed are the most important factors for good dispersion. If you use the right surfactant and solvent, you can maximize the effect.

Note: Always test your mixture before full production. This helps you catch problems early and adjust your process for a smooth finish.

Five Star Aluminium Paste helps you avoid clumping and gives you a consistent metallic look. You get a professional result every time when you follow these steps.

Application techniques

Heating and bonding methods

It is important to watch how you heat and bond powder coatings with metallic pigments. The way you do this step changes how well the pigment sticks. It also changes how shiny the finish looks. If you heat the powder until it feels a little sticky, the metallic flakes can stick to the powder. This step helps make the surface smooth and even.

There are different ways to bond the pigment. Each way has good and bad points. The table below shows how each heating and bonding method changes how well the finish sticks and how it looks:

| الطريقة | المزايا | Drawbacks |

|---|---|---|

| Cold Bonding | Fully bonded product fixes non-bonding problems. | Metallic pigment can be uneven; extra powder cannot be reused. |

| Melt-Extrusion | Metallic flakes stick well and process is stable. | High heat can change pigment size and ruin the look; not used for every job. |

| Thermal Bonding | Makes the finish shiny and even; solves other problems. | Needs careful temperature control; can bond wrong or start curing too soon; process is hard. |

Thermal bonding is best if you want a shiny and even finish. You must watch the temperature closely. Too much heat can hurt the metallic flakes. Too little heat means the flakes may not stick well. Five Star Aluminium Paste works well with thermal bonding. You get a bright and even finish if you follow the right steps.

Tip: Always heat the powder until it feels a bit sticky before adding metallic pigments. This helps the flakes stick and gives you a smooth, professional finish.

Spray parameters and thickness

Spraying is another important step for a smooth powder finish. You need to set your spray settings right and check the coating thickness. If you spray too much or too little, you can lose the mirror look or get rough spots. The table below shows how different things change how smooth and shiny your finish is:

| العامل | Influence on Smoothness and Reflectivity |

|---|---|

| سُمك الطلاء | Keep the coating between 5–10 microns. Too thick or thin changes the mirror look. |

| ظروف التجفيف | Watch the temperature and humidity when drying. This stops problems like bumps or holes. |

| Spraying Technique | Use electrostatic spraying (ESTA) to spread aluminum paste evenly. This makes the film thicker. Change solvent systems to lower surface tension and help the powder spread. |

You should always check how thick your powder coating is. If you use too little, it will not protect against rust. If you use too much, the finish can peel or crack. Test often to keep the coating in the right range. Five Star Aluminium Paste gives a steady metallic look when you control the spray thickness.

Here are some best ways to check and control spray thickness:

- Hang your parts the right way to keep the coating even.

- Control how much powder comes out of the gun.

- Keep your spray pattern steady for even coverage.

- Measure the film thickness often to check quality.

- Use the same steps for every part of the process.

- Measure powder coating thickness to protect against damage.

- Test often to meet what the maker says.

- Change your process if you see too much or too little coating.

Note: You get the best results if you follow these steps and use good products like Five Star Aluminium Paste. Your finish will look smooth and last a long time.

Curing and care

Curing temperature and time

You need to cure your powder-coated aluminium at the right temperature and for the right amount of time. This step makes your finish strong and shiny. If you use Five Star Aluminium Paste, you want to get the best results. The best curing temperature is 160°C. The ideal curing time is 10 minutes. These settings help your coating last longer and look better.

- Set your oven to 160°C.

- Keep the parts inside for 10 minutes.

- Check the temperature with a thermometer.

If you do not cure the coating properly, you may see problems. The finish can fade or lose its shine. The powder may not stick well. You might notice chips or scratches more easily. The coating can also wear out faster in the sun or rain. Good curing helps the polymer chains link together. This makes your finish tough and weather-resistant.

Tip: Always follow the curing instructions for Five Star Aluminium Paste. You will get a smooth, bright finish that lasts.

Handling and storage

After curing, you must handle and store your powder-coated aluminium with care. This keeps the surface looking new and stops damage. You can follow these steps:

- Clean the coated parts often. Use warm water and mild detergent with a soft cloth. This removes dirt and keeps the shine.

- Avoid strong chemicals. Use neutral or pH-balanced cleaners. Harsh chemicals can harm the coating and dull the metallic effect.

- Inspect the surface for chips or scratches. Fix any damage quickly to prevent rust or corrosion.

- Protect your parts from bad weather. Use covers or wax to shield them from rain and sunlight.

| Care Step | لماذا هذا مهم |

|---|---|

| Gentle cleaning | Keeps finish bright and smooth |

| No harsh chemicals | Protects metallic shine |

| Regular inspection | Stops rust and keeps coating strong |

| Weather protection | Prevents fading and surface damage |

If you use Five Star Aluminium Paste, these steps help your finish stay beautiful and strong. You will see fewer problems and enjoy a longer-lasting metallic look.

Troubleshooting

Surface defects and fixes

Sometimes, you might see problems on the surface when using pigment aluminium powder coatings. These problems can make the finish look bumpy or not smooth. Most of these issues can be fixed if you know what causes them and how to solve them.

Here is a table that lists common problems, why they happen, and how to fix them:

| Surface Defect | Cause | Solution |

|---|---|---|

| Weld Splatter | Weld spatter from welding part | Strip coating, grind spatter with clean tool carriage |

| Outgassing | Air or gas trapped inside the casting | Out gas the part at a higher temperature than cure cycle |

| Laser Cutting | Laser scale during cutting process | Remove scale by grinding or sanding the surface |

| Dirt on Surface | Contaminated coating material or external sources | Screen powder and control airborne contamination |

| Particles | Burrs, chips, or residues from aluminum profiles | Use brushing and cleaning machines before pretreatment |

You can stop many problems by keeping your work area clean. Dust from clothes, shoes, or floors can land on your parts. Pollen and dirt from outside can come in through open doors. Machines can also make dust and dirt. You should screen used powder and use rotary sieves before spraying. Five Star Aluminium Paste works best when you keep things clean and get surfaces ready.

Tip: Always check your powder and tools before you start. Clean tools and filtered powder help you avoid problems on the surface.

Adjusting process variables

You can make your powder finish better by changing some settings. Temperature, humidity, and spray speed all change how your coating looks and lasts.

- If the temperature is too low, the paint gets thick and does not spread well. You might see big drops and rough spots.

- If it is too hot, the solvents dry too fast. This can make the finish look uneven and not shiny.

- Humidity is important too. High humidity makes drying slow and can make the coating sag. Low humidity can cause static and change how the spray works.

You should keep these settings in a small range. This helps you get a smooth, even finish and bright color. If you see problems like bad flow, holes, or poor sticking, you can use this troubleshooting table:

| Problem | Probable Cause | Solution |

|---|---|---|

| Poor flow | Film thickness too high/low | Adjust equipment and thickness |

| Poor adhesion | Pre-treatment or under cured | Clean parts and increase cure temperature |

| Cratering | Contamination | Clean gun, hopper, and spray booth |

| Dripping | Cure temperature too high | Reduce oven temperature and/or time |

| Lumps or packed powder | Improper storage | Screen and sieve powder before spraying |

You can trust Five Star Aluminium Paste to give you good results. If you follow these steps and change your process when needed, you will see fewer problems and get a smooth, professional finish every time.

Special considerations

Heat management benefits

Pigment aluminium does more than make things shiny. It also helps control heat. When you use powder coatings with pigment aluminium, you can keep things cooler. This is important for cars, electronics, and plastic parts.

Here is a table that shows how pigment aluminium helps in different ways:

| Application Area | Benefit Description |

|---|---|

| Plastic Materials | Helps stop heat from building up. This is important for electronic enclosures. |

| طلاءات السيارات | Bounces heat away, so cars do not get as hot. |

| Electronic Enclosures | Makes things last longer by keeping them cooler. |

Pigment aluminium reflects heat. This keeps surfaces cool and protects important parts. Five Star Aluminium Paste gives you these heat control benefits. Your finish will look nice and work well, even in tough places.

Tip: Pick pigment aluminium if you want a bright finish and better heat control.

Application differences for metallics

Using metallic pigment aluminium is not the same as using regular powder coatings. You need to follow special steps to get good results. Metallic coatings often need more than one layer. This helps make the finish smooth and even. Regular powder coatings usually need just one coat.

Here is a table that compares the two types:

| ميزة | Metallic Pigment Aluminum | Non-Metallic Powder Coatings |

|---|---|---|

| Application Technique | Needs more than one coat | Usually just one coat |

| التكلفة | Costs more because of extra layers | Cheaper and uses less material |

| التأثير البيئي | Has solvents, not as good for the planet | Better for the environment |

| Finish Quality | Only some finishes are possible | Many colors and textures |

| المتانة | Not as strong as regular powder coatings | Very tough and resists chemicals |

| Use in Harsh Environments | Does not work as well in hard places | Works great in tough spots |

| Popularity in Architecture | Used sometimes but not for all finishes | Getting more popular for buildings |

You should always clean and treat the surface before using metallic coatings. Clean, degrease, and get the surface ready so the powder sticks well. Aluminium can get an oxide layer, so you need special treatments. If you see problems like bubbles or poor sticking, change your cleaning or curing steps. Five Star Aluminium Paste works best when you follow these special steps.

Note: Good cleaning and the right steps help you get a smooth, long-lasting metallic finish.

You can get a smooth powder finish if you follow some easy steps. First, clean and get your surface ready. Pick the right pigment aluminium for your job. Mix everything gently so you do not break the flakes. Put the powder on in an even layer. Cure it at the right heat and for the right time. If you use Five Star Aluminium Paste, your finish will last a long time. It will not chip or get ruined by bad weather.

- Powder coatings make your surface thicker and stronger.

- Using electrostatic spray helps stop mistakes and keeps the finish nice.

- Fewer errors mean you do not have to fix things as much. Customers will be happier with your work.

Try these tips when you work on your next project. Tell us how it goes or ask questions below. Your ideas help everyone get better.

الأسئلة الشائعة

What makes Five Star Aluminium Paste different from other brands?

Five Star Aluminium Paste gives a shiny look every time. It protects surfaces from rust and damage. The paste spreads out smoothly on your project. Many people use it for inside and outside jobs.

How do you prevent clumping when mixing pigment aluminium?

Mix the pigment aluminium slowly and gently. Add a dispersant to help flakes spread out. Five Star Aluminium Paste works with dry-blend and bonding ways. Always test your mix before making a lot.

Can you use pigment aluminium powder coatings outdoors?

You can use pigment aluminium powder coatings outside. Five Star Aluminium Paste stands up to rain and sun. Clean and prime the surface first for a finish that lasts longer.

What is the best way to clean powder-coated aluminium surfaces?

Clean with warm water and a gentle soap. Use a soft cloth to wipe the surface. Do not use strong chemicals. Five Star Aluminium Paste helps your finish stay bright and smooth if you care for it this way.