You can pick from many powder coating paints. There are thermoset and thermoplastic styles. These finishes work for lots of things. They are used for consumer goods and also for industrial jobs. For example:

- Consumer goods have 24.1% of the market. They are popular because they last long and look nice on appliances.

- Polyester resins make up 26.4% of the market. They are good for tricky shapes and hard places.

| ميزة | Thermoplastic Coatings | Thermosetting Coatings |

|---|---|---|

| Flexibility | عالية | Moderate |

| المتانة | Good | Superior |

| Repairability | Easy | Difficult |

Picking the right finish gives you better protection. It also makes your project look good and work well.

النقاط الرئيسية

- Powder coating gives a strong finish. It does not chip, scratch, or fade easily. This makes it good for outdoor furniture and appliances.

- You can pick thermoset or thermoplastic coatings. Thermoset works well with high heat. Thermoplastic is bendy and can be recycled.

- Pick the finish you want. You can choose gloss, matte, or textured. Each finish looks different and is easy to care for in its own way.

- Think about things like humidity and UV light before you use powder coating. This helps your finish last longer and look better.

- If you want your product to stand out, use Aluminium Paste in your powder coating. It gives a shiny, metallic look that makes your product more attractive.

What Is Powder Coating?

Process Overview

Powder coating is a modern way to protect and decorate metal and other surfaces. You use powder coating paints instead of liquid paint. The process starts with cleaning and degreasing the item. This step removes dirt and oil so the powder sticks well. Next, you roughen the surface with abrasion. This helps the powder grip the material. You may add a conversion coating to make the item resist rust and improve how the powder bonds.

After these steps, you rinse the item to wash away chemicals. Drying comes next. This stops water spots from forming. You choose the right pretreatment for the material. You check the pH and control the temperature, water conductivity, and spray nozzle pressure. These steps make sure the finish looks good and lasts long. The final step is curing. You heat the item so the powder melts and forms a smooth, hard layer.

Here is a simple list of the main steps:

- Cleaning and degreasing

- Abrasion

- Conversion coating

- Rinsing

- Drying

- Pretreatment selection

- pH measurement

- Control of temperature, water, and spray pressure

- Curing

Benefits of Powder Coating

Powder coating gives you many advantages over traditional paint. You get a finish that resists chipping, scratching, and fading. This makes it great for outdoor furniture, car parts, and appliances. Powder coatings emit almost no harmful fumes, so you help keep the air clean and meet safety rules.

You also save money. The process uses less energy and creates less waste. You do not need expensive pollution-control equipment. Powder coating paints last longer, so you spend less on repairs and replacements.

| Evidence Type | الوصف |

|---|---|

| Environmental Benefits | Powder coatings have low or zero VOC content, meeting EPA and EU standards. |

| مزايا الأداء | They resist corrosion, heat, and electricity, making them ideal for many uses. |

| Cost-Effectiveness | The process is solvent-free and lowers overall costs. |

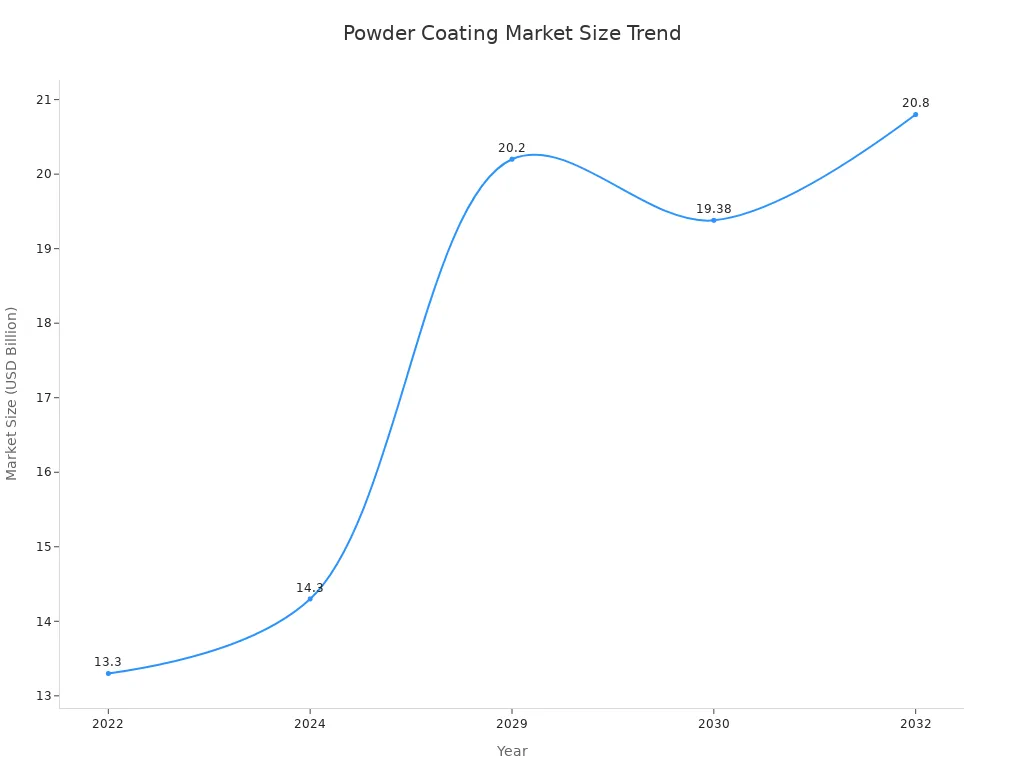

The global market for powder coating keeps growing. You can see the steady rise in market size in the chart below:

Tip: Powder coating is a smart choice if you want a strong, eco-friendly finish that saves money and lasts for years.

Types of Powder Coating Paints and Finishes

Thermoset vs. Thermoplastic Styles

You can pick thermoset or thermoplastic powder coating paints. Each one works in a different way. This changes how your finished item will act.

Thermoset powder coating paints make a strong bond when heated. You cannot change their shape after they cool down. These coatings are good for things that get hot or used a lot, like electronics and appliances. Thermoset coatings stop rust and come in many colors and finishes. People use them on machines and car parts.

Thermoplastic powder coating paints can be melted and shaped again with heat. This means you can recycle them, so they are better for the environment. They feel soft and are good at stopping electricity. Thermoplastic coatings do not break easily and protect against water. They are great for things that need to bend or stay dry.

هنا table to help you see the differences:

| الممتلكات | Thermoplastic Powder Coatings | Thermoset Powder Coatings |

|---|---|---|

| Heat Resistance | Not ideal for high heat exposure | Suitable for high heat applications |

| Flexibility | Reversible, can be reshaped and remolded | Irreversible, less flexible but offers high tensile strength |

| المتانة | Strong, durable, resistant to impact and wear | High tensile strength, suitable for heavy wear and tear |

| التأثير البيئي | More sustainable, can be recycled | Less sustainable, cannot be reshaped or recycled |

Tip: Use thermoset powder coating paints for outdoor furniture or machines. They protect well from heat and rust. Pick thermoplastic coatings if you need something flexible or easy to recycle.

Gloss, Matte, and Textured Finishes

Powder coating paints come in many looks. You can choose shiny, soft, or bumpy styles. Textured finishes hide marks and help you grip things.

- Gloss finishes are shiny and look nice. You can clean them easily, so people use them for appliances and medical tools. But, gloss finishes show marks and need a smooth surface.

- Matte finishes look soft and do not shine much. They are good for factories and outside things. Matte coatings do not reflect light, so they are not as bright as gloss.

- Textured finishes cover up scratches and dents. You can pick how rough you want it. Textured coatings may not be as shiny and can feel rough.

هنا table that shows the good and bad parts of each finish:

| Finish Type | المزايا | العيوب |

|---|---|---|

| لمعان | Easier to clean, less surface friction, visually appealing | Higher surface preparation costs, imperfections visible |

| شديد اللمعان | Very shiny, great for cleaning, ideal for industries like medical and food processing | Requires a very even surface, can highlight imperfections |

| Matte | Soft appearance, minimal glare, suitable for industrial and outdoor applications | Less reflective, may not be as easy to clean |

| Textured | Hides surface imperfections well, can be customized | May restrict available gloss levels, rough finish may not suit all applications |

Thicker powder coating paints protect better. If you use more paint, your item will last longer and not rust as fast. This is important for things that stay outside or touch chemicals. Always follow the rules for how thick to make the coating. If it is too thick, it can peel or not dry right.

Note: Thicker coatings last longer and protect better, but too much can cause issues. Thin coatings do not offer as much durability.

Specialty Effects (Metallic, Pearlescent, Candy)

You can make special looks with powder coating paints. These finishes make your things look cool and worth more.

- Metallic finishes use Aluminium Paste or flakes to sparkle. You see these on car wheels, electronics, and decorations. Five Star Aluminium Paste is a good brand for shiny metallic powder coating paints. It helps you get a bright, even look.

- Candy colors use a clear top layer over a metallic base. This makes a deep, rich color for bikes, cars, and custom furniture.

- Pearlescent finishes give a soft glow. You can mix pearlescent pigments with Aluminium Paste for a special shine.

- River and vein effects look like stone or metal. People use these for wall panels and building designs.

- Tinted coatings protect the main color and change how it looks. You can use these to match your brand or style.

Callout: If you want a special look, try metallic or pearlescent powder coating paints with Aluminium Paste. These finishes work well for automotive, electronics, and consumer goods.

Powder coating paints let you use thicker layers than liquid paint. This means your things will not rust as fast and will last longer. Thick coatings are important for things that face tough weather or hard work, like outdoor railings or big machines. Do not use too much paint, or it will not dry right.

You can use powder coating paints in many places:

- Automotive: Wheels, bumpers, and trim need to look good and not rust.

- Construction and Architecture: Metal frames and railings need to last a long time.

- Industrial Machinery: Epoxy coatings make machines tough and safe from chemicals.

- Consumer Goods: Appliances and furniture look smooth and last longer.

Common types of powder coating paints are:

- Epoxy: Used for cars, electrical parts, and big machines.

- Polyester: Good for things outside like window frames and fences.

- Epoxy-Polyester Hybrid: Great for indoor furniture and office stuff.

- Acrylic: Used for car clear coats and home items.

- Fluoropolymer: Picked for buildings that need strong protection.

Tip: When you pick powder coating paints, think about the finish, thickness, and special effects. Using Aluminium Paste can help you get the look and strength you want.

Powder Coating Paints: Colors and Customization

Standard and Custom Colors

Powder coating paints come in many colors. You can pick basic colors like white, black, blue, red, green, or yellow. These colors work for most things and help keep everything looking the same. If you want a special color, you can ask for it. Experts mix pigments to match what you need. Companies use systems like RAL to make sure colors always look the same.

Metallic finishes like gold, silver, bronze, or copper look fancy. Aluminium Paste helps make these metallic colors bright and smooth. You can also choose textured finishes. These make your product interesting and hide marks. Special effects like gloss, satin, or matte change how your product looks and feels.

Tip: If you need a certain color for your brand, ask about color matching. Experts use special tools to match colors and check quality. This way, your products always look the same.

When you pick a color, think about these things:

- Where you will use it (outside, inside, near chemicals)

- What you are coating (steel, aluminum, composites)

- The finish you want (matte, satin, high-gloss)

- How you will put on the coating (electrostatic spray, fluidized bed)

- The mood you want (bright, bold, subtle, or fancy)

Multi-Color and Pattern Effects

Powder coating paints let you make designs with more than one color. You can use patterns to show your style or brand. Some companies have glow-in-the-dark colors or special mixes for cool projects. You can layer colors or use masking to make stripes, fades, or logos.

Aluminium Paste is good for making custom metallic patterns. You can mix it with pearlescent pigments for extra shine. If you want texture, you can pick from smooth to rough. These choices help you match your product to your customers and where it will be used.

Note: Always talk to experts about your design ideas. They can help you choose the best colors, finishes, and ways to apply the coating for great results.

Choosing the Right Finish and Style

Material and Surface Preparation

You want your powder coating paints to last and look nice. You need to get the surface ready first. Here are the steps you should follow:

- Clean the surface so there is no dirt or dust.

- Take off any rust from the metal.

- Use a degreaser to remove oil.

- Etch the surface if you need to make it rough.

- Cover spots that should not get coated.

- Warm up the surface to help the paint stick.

- Check the surface to see if it is ready.

If you do not clean well, dirt, oil, or rust can make the coating weak and cause trouble later.

- Pick a cleaning method that matches the kind of dirt you have.

- Make sure your cleaning is not too expensive and works well.

Environmental and Application Factors

Think about where you will use your coated item. Things like humidity, heat, and sunlight can change how powder coating paints work. Look at الجدول أدناه to see what happens with each factor:

| Environmental Factor | Effect on Powder Coating Performance |

|---|---|

| UV Light | Makes the color fade and lose shine. |

| درجة الحرارة | High heat causes cracks and fading. Cold makes coatings break easier. |

| Humidity | Too much water in the air makes the coating not stick well and can cause mold. |

- High humidity can leave water on the surface and cause rust.

- If you see water drops, dry them before coating to stop peeling.

Keep powder-coated things between 68 and 80 degrees Fahrenheit. This helps the color stay bright. Sunlight can make colors fade, but powder coating paints keep their color better than liquid paint.

Appearance and Branding

Powder coating paints help your products look special. They do more than just protect. You can pick colors, textures, and effects to match your brand.

- Makers of appliances, bikes, and electronics use cool finishes to get people’s attention.

- Wrinkle and soft-touch textures make things feel different.

- Custom colors and effects help machines stand out and show your company’s style.

We do not just sell powder coating paints. We help you get better quality and save time, which helps your brand look good.

If you want a shiny look, try Aluminium Paste in your finish. It makes your products look bright and modern.

Pros and Cons of Powder Coating Finishes

Durability and Maintenance

Powder coating makes a tough finish that lasts a long time. Most powder-coated things stay nice for 15 to 20 years. If you care for them, some can last up to 25 years outside. Powder coatings stand up to sun, water, heat, and chemicals. This is why people use them for outdoor furniture, bikes, and machines.

You should clean powder-coated things often. Use gentle soap and water every few months. Do not use strong cleaners. Rinse well after washing. If you see stains like graffiti or bird droppings, use a soft brush and mild soap. For things outside, use covers and check for damage often. These steps help your finish stay bright and strong.

- Powder coating does not chip or scratch easily.

- You do not have to repaint often.

- Special finishes with Aluminium Paste look shiny and protect more.

Tip: Powder coating is easier to care for than liquid paint. You save time and money over the years.

Cost and Application Challenges

Powder coating costs more at first than liquid paint. You need special tools and ovens. But you save money later because it lasts longer and needs fewer fixes. The material cost for powder coating is less for each square foot than liquid paint. You also use less powder and make less waste.

| الفئة | Powder Coating Cost | Liquid Painting Cost | Savings per Square Foot |

|---|---|---|---|

| التكلفة المادية | $2.29 | $3.52 | $1.23 |

| Coverage Efficiency | 128.8 sq ft/lb | 365 sq ft/gallon | N/A |

| Maintenance Frequency | Less frequent | More frequent | N/A |

| التأثير البيئي | Lower (no VOCs) | Higher (contains VOCs) | N/A |

You may have problems when putting on powder coating. Sometimes, the powder does not cover the whole thing. You might see orange peel or pinholes if you do not clean well. Always follow the right steps for cleaning, pretreatment, and curing. Use the right thickness for each coat. If you use Aluminium Paste, mix it well for a smooth metallic look.

- You may not get full coverage if you do not use enough charge.

- Orange peel happens if the powder mix or curing is wrong.

- Pinholes show up if air or water gets trapped.

Note: Powder coating works best on metal and some plastics. You need special tools and ovens. It is harder to fix than liquid paint.

| Advantages of Powder Coating | Disadvantages of Powder Coating |

|---|---|

| Strong coating | Can get worse from UV light |

| Affordable | Big cost to start |

| Many colors and finishes | Hard to do thin coats |

| Needs little care | Slow color change compared to others |

| Fast to apply | Powders cannot be mixed for new colors |

| Goes on evenly | Needs special equipment |

| No toxic fumes | All coating must be baked |

| Good for the planet | Hard to fix small spots |

| Can be recycled | Does not work on all things |

| Wastes less powder | Less control over the process |

Powder Coating vs. Other Methods

Liquid Paint Comparison

You might wonder how powder coating and liquid paint are different. Powder coating lasts longer and is tougher. It gives a thicker layer, so your things do not chip or fade easily. Liquid paint can look shiny and smooth. But it can crack or peel, especially outside.

Powder coating is better for the planet. It does not let out bad fumes. Liquid paint can send VOCs into the air, which are not safe. You can recycle extra powder. Leftover liquid paint is hard to throw away and can hurt water.

With powder coating, you have lots of choices. You can pick glossy, matte, or textured finishes. You can add Aluminium Paste for a shiny, metallic look. Liquid paint gives a smooth finish, but not as many styles or as much strength.

إليك جدول لمساعدتك في المقارنة:

| الجانب | Powder Coating | Liquid Paint |

|---|---|---|

| المتانة | More resistant to chipping, scratching, fading, and wear; ideal for harsh environments. | Prone to cracking, peeling, and chipping over time, especially in extreme conditions. |

| التأثير البيئي | Minimal VOC emissions; can be recycled; energy-efficient curing process. | Releases VOCs during application; potential water contamination; disposal challenges. |

| Finish Quality | Offers a wide range of customizable finishes, including textures and gloss levels. | Provides smooth, high-gloss finishes but may lack long-term durability compared to powder coating. |

Tip: If you want a finish that lasts and helps the earth, powder coating is a smart pick.

Anodizing and Plating Comparison

You can also use anodizing or plating for your projects. Each way works differently and gives you different results.

- Powder coating puts a strong layer on your item. It stops rust and blocks UV rays. You can use Aluminium Paste for a shiny look.

- Anodizing uses electricity to make a hard layer on aluminum. It protects well and lets you add color. But it costs more because it uses a lot of energy.

- Electroplating adds a thin metal layer. How well it works depends on the metal you use. Plating can cost more and takes more steps.

Here is a quick look at the differences:

| Process | الوصف | Cost Comparison |

|---|---|---|

| Powder Coating | Applies a thick, durable layer; resists corrosion and UV; many finish options with Aluminium Paste. | Usually less expensive than anodizing and plating. |

| Anodizing | Makes a hard, colored oxide layer on aluminum; very weather-resistant. | More expensive due to energy use. |

| Electroplating | Adds a thin metal layer; performance depends on the metal used. | Can be costly because of materials and process. |

Pick the way that fits what you need. Powder coating works for most metals and gives you lots of colors and textures. Anodizing is best for aluminum if you want it extra hard. Plating is good for a metal look, but it may not last as long as powder coating.

Note: Powder coating with Aluminium Paste gives you both strength and style. That is why many people choose it for their projects.

You have many powder coating finishes and styles to choose from. Thermoset and thermoplastic coatings offer different strengths. Gloss, matte, and textured looks help you match your needs. Always check the material, the environment, and the look you want. For best results, follow these tips:

- Pick a provider with experience and certifications.

- Make sure they use proper surface preparation.

- Ask about turnaround time and insurance.

- Avoid mistakes like poor cleaning or wrong curing.

Powder coating gives you a strong, long-lasting finish. It needs less care, works well outdoors, and helps protect the planet. If you want a bright, metallic look, ask about Aluminium Paste in your finish.

الأسئلة الشائعة

What surfaces can you powder coat?

You can powder coat metals like steel and aluminum. Some plastics and composites work too. Aluminium Paste helps you get a shiny finish on metal surfaces. Always check if your material can handle the heat from curing.

How do you choose the right powder coating finish?

You look at where you use the item and what you want it to look like. Gloss, matte, and textured finishes work for different needs. If you want a metallic effect, ask for powder coating paints with Aluminium Paste.

Can you customize colors and effects with powder coating?

Yes, you can pick standard colors or ask for custom shades. You can add special effects like metallic, pearlescent, or candy finishes. Aluminium Paste helps you get bright, smooth metallic looks for your project.

How long does powder coating last?

Powder coating lasts 15 to 20 years. You get longer life if you clean and care for it. Outdoor items with Aluminium Paste finishes stay shiny and strong for many years.

Is powder coating safe for the environment?

Powder coating uses no harmful solvents. You get low or zero VOC emissions. You can recycle leftover powder. Aluminium Paste in powder coating paints does not add toxic fumes, so you help keep the air clean.