Your Best DEG Aluminum Paste Manufacturer and Supplier in China

- 20 Years of Industrial Experiences

- Provide OEM and ODM Services

- Achieved PAHs and RoHS Certificates

- 3,000 Tons of Aluminum Paste Annually

- 30 Technical R&D Engineers Providing Technical Support

DEG aluminum paste for AAC

AAC Aluminum Paste Supplier

Alu Paste for ALC Blocks Expert

Aluminum Paste for AAC Blocks

Custom Aluminium Paste Solutions

DEG Aluminum Paste

Aluminum Paste for Lightweight Concrete Brick

Specification of Aluminium Paste & Powder for AAC

| Product Name | Solid Content (%) | Active Alumina (%) | Bulk Density | Median Particle Size (D₅₀) | Suitable for AAC |

|---|---|---|---|---|---|

| DEG-60 | 70% | ≥96 | 0.15 | 58–62 | <600 |

| DEG-40 | 70% | ≥94 | 0.15 | 36–42 | <500 |

| DEG-35 | 70% | ≥94 | 0.15 | 33–35 | <400 |

| DEG-25 | 70% | ≥94 | 0.15 | 25–27 | <400 |

| DEG-18 | 70% | ≥92 | 0.11 | 17–19 | <350 |

Aluminium Paste & Powder for AAC

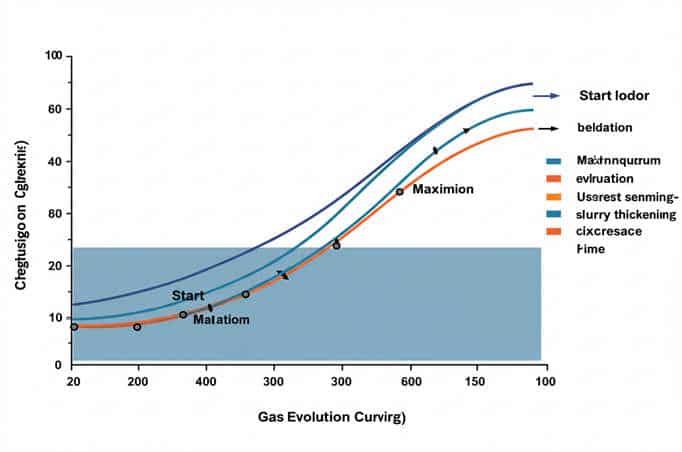

Aluminium Paste & Powder (APP) is a crucial aerating agent in producing AAC blocks. It reacts with alkaline substances to release hydrogen gas, forming a lightweight, porous structure. Below are the key aspects:

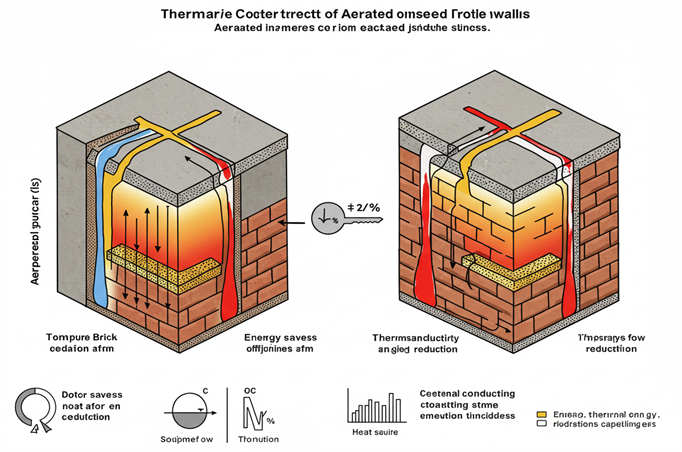

1. Function & Reaction Mechanism

1.1 Aeration Principle

In an alkaline environment (e.g., Ca(OH)₂), Aluminium Paste & Powder reacts with water to produce hydrogen gas:

2Al+3Ca(OH)2+6H2O→3CaO⋅Al2O3⋅6H2O+3H2↑

This reaction creates uniformly distributed pores within the slurry, reducing the final product density to 500-700 kg/m³—only one-fifth of conventional concrete.

1.2 Pore Structure Impact

The size and distribution of pores directly determine AAC’s insulation and soundproofing properties. To achieve an ideal pore structure, the aluminum particles must have a suitable fineness (≤3% residue on a 0.075mm sieve) and a high active aluminum content (≥85%).

2. Production Process & Technical Requirements

The production process of aerated aluminum paste (slurry)/powder is crucial in determining the final product’s quality and performance. This chapter will detail the production flow, key technologies, and control points of each stage in the manufacturing process of aerated aluminum paste (slurry)/powder to help readers better understand the manufacturing of this critical material.

2.1 Production Flow

The production flow of aerated aluminum paste (slurry)/powder typically includes the following main steps:

2.1.1 Raw Material Preparation

Before production begins, the selection and Preparation of raw materials are crucial. The main raw materials include aluminum powder, additives (such as DEG, dispersants, etc.), and other ingredients. The selection of aluminum powder is usually based on its particle size, activity, and purity. Highly active aluminum powder can generate more hydrogen gas when reacting with water, thus achieving better gas generation effects. The selection of additives needs to consider their role in the aerated aluminum paste, such as improving fluidity and enhancing reactivity.

3. Application Advantages & Market Trends

3.1 Comparison Between Aluminum Paste and Traditional Dry Aluminum Powder

| Characteristic | Aluminum Paste (Water-based) | Dry Aluminum Powder |

|---|---|---|

| Production Process | Wet grinding, no need for degreasing | Dry grinding, requires degreasing |

| Safety | No dust explosion risk | Flammable and explosive, requires nitrogen protection |

| Ease of Use | Directly added to slurry, good dispersion | Requires pre-degreasing treatment |

| Environmental Impact | Low pollution, easy wastewater treatment | High energy consumption, more pollution |

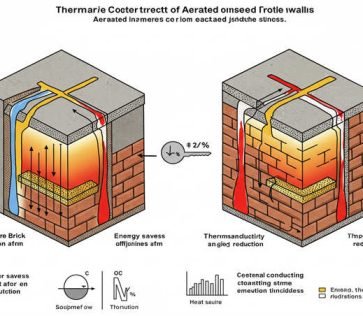

3.2 Performance Advantages

- Lightweight & High Strength: Reduces building weight by over 40%, enhancing earthquake resistance.

- Thermal Insulation: Thermal conductivity ranges from 0.11 to 0.16 W/m·K, outperforming traditional brick walls.

- Ease of Construction: The material can be cut and drilled, allowing for flexible applications in complex structures.

3.3 Market Trends

- Price Fluctuations: Aluminium prices and energy costs influence market pricing, which will average around ¥10,000 per ton in 2024.

- Regional Supply & Demand: Major production areas include Anhui, Shandong, and Jiangsu, while demand in the southwest region is growing significantly.

Main Products-Five Star Materials

Get what you need even the customized Aluminum Pigment Paste

Sophisticated Silk sparkle Paste

Silver-white Paste

Silver Round Series Strong Flashingaluminum Silver Paste

Advanced Aluminum Paste

Vacuum Metallized Pigments

Silver Dollar SeriesExtra Fine White Bright Aluminum Silver Paste

Water borne Aluminium Paste

Resin Coated Slurry Aluminum Pigment

Water borne Floating Aluminium Paste

Why Choose Five Star Materials

5 Star Materials Wish to Be Your Trust-able Aluminum Pigment Paste Manufacturer

Advanced Production Technology and Equipment

Equipped With a First-Class Domestic Product Testing Center and Advanced Production Technology and Facilities to Ensure Product Quality Meets International Standards.

High Quality Products

The Aluminum Pigment Paste with Fine and Concentrated Particle Size Distribution With Strong Hiding Power and Anti-tarnishing Performance, as Well as Superb Acid/Alkali Corrosion Resistance, Excellent Weather Resistance and Insulation.

Stable Development

Maintained comprehensive, stable and sustainable development in recent years, with good economic benefits and strong market competitiveness.

Patented Technologies

Obtained National Utility Model Patents That Filled Domestic Gaps and Reached Domestic Advanced Level.

High-Tech Enterprise

Recognized as a high-tech enterprise through the transformation and implementation of new products and technologies.

Excellent Business Management

Implement Advanced Management Models Like Tqm and 6s, Organize Production and Operation According to ISO9002 Quality System.

who we are

Five Star Materials

Five Star Materials as a leading Aluminum pigment paste manufacturer and supplier in China,we Builds a Factory With High Standard, and Configured With Domestic First-Class Product Testing Center, Adopts Modern, Efficient and Scientific Management to Strengthen On-Site Management, and Organizes Production, Operation and Sales in Accordance With the Requirements of ISO9002 Quality System Certification, Centering on Tqm, 6s

Five Star Materials’ mission has been to develop and produce the highest quality metallic pigments, aluminum foils and aluminum profiles. With an annual production capacity of 2,000 tons of metallic pigments, 2,000 tons of aluminum foils and 2,500 tons of aluminum profiles, this amazing capacity is an important pillar of our leading position in aluminum pastes in China.

Certificates

Five Star Materials’ products are PAHs and RoHS certified and are widely used in automotive coatings, consumer electronics, plastics, glass decoration, sunshade coating, ships and petrochemical pipeline anti-corrosion.

Five Star Materials builds a high standard factory, equipped with domestic first-class product testing center, adopts modern, efficient and scientific management to strengthen on-site management, and organizes production, operation and sales in accordance with the requirements of ISO9002 quality system certification, centering on TQM, 6S and so on.

Customers reviews

What People Say

You Are Looking For More Than Just a Simple Aluminum Paste, You Need an Experienced Aluminum Pigment Paste Manufacturer Partner With Nearly 20 Years of Experience in the Aluminum Paste Industry Just, Ready to Provide Solutions for Your Needs, Let Five Star Materials Be Your Trusted Aluminum Paste Supplier!

Questions Customers Often Ask When Looking for DAluminum Paste for AAC BlockFactory

Yes, we are a professional manufacturer of DEG Aluminium Paste with many years of production experience and advanced production technology.

The quality indexes of Aluminum Paste for AAC Block in our factory are as follows:

Solid containing: 70±1

Delayed aerating time: 1-3 minutes

Activated aluminium: ≥92

Particle size uniformity: high

The price of Aluminum Paste for AAC Block in our factory depends on the specific model and quantity, please contact us for detailed quotation.

The minimum order quantity of DEG aluminium slurry from our factory is 1 ton,it is depends.

Our factory provides the following after-sales service:

Product quality guarantee

Technical guidance

After-sales service tracking

Yes, we can customize the production of DEG Aluminium Paste according to customers’ requirements.