Different Types of Aluminum Corrosion

Corrosion has always been a prevailing problem in using metal for structures, machinery, and products. Since it exposes gradual damage over materials it is a primary challenge for industries as they become inherently part of the daily struggles in maintenance and safety. As a common material that has been actively used in modern structures or components, aluminum is one of the metals that encounter the problem of corrosion in its external and internal composition. This article will delve into the classification and types of aluminum corrosion to indulge knowledge and information in interested individuals.

2 Classifications of Aluminum Corrosion

- General Corrosion – is also called uniform corrosion as this type of corrosion expands over the entire metal surface uniformly or sometimes over a large area. This corrosion is a result of electrochemical reactions caused by aqueous or atmospheric elements.

- Local Corrosion – is a type of corrosion that targets a specific area on metal surfaces. Local corrosion can be hard to spot at first as it can occur in non-visible locations which are often in small sizes.

Types of Aluminum Corrosion

Pitting

A form of local corrosion called pitting causes caves or pits in aluminum to expand and sometimes even result in perforations. Pitting can be characterized by the diameter of the pit opening, whether it is smaller than the depth or greater it is considered as corrosion in the form of pitting. The main reason for pitting can be due to the difference in substrates and impurities in aluminum elements.

Galvanic Corrosion

When a less reactive metal and more reactive metal come in contact with the same environment it accumulates enough form of galvanic couple to cause galvanic corrosion. Depending on the types of metal that come together, two unfavorable combinations can execute extreme reactions or more serious galvanic corrosion. Aluminum and aluminum alloys are often susceptible to this type of corrosion since it is always anodic.

Stress Corrosion Cracking

From the name itself, stress corrosion cracking appears as tiny cracks in the external surface of the metal. This corrosion is caused by the coexistence of certain conditions such as tensile strength and specific corrosive media. Other reasons for stress corrosion cracking include severe temperature changes and volume changes in internal structure.

Laminar Corrosion

This type of corrosion can be found in aluminum series of 2000, 5000, 6000, and 7000 aluminum alloys. Laminar corrosion is also known as layered corrosion as it occurs by peeling layer by layer.

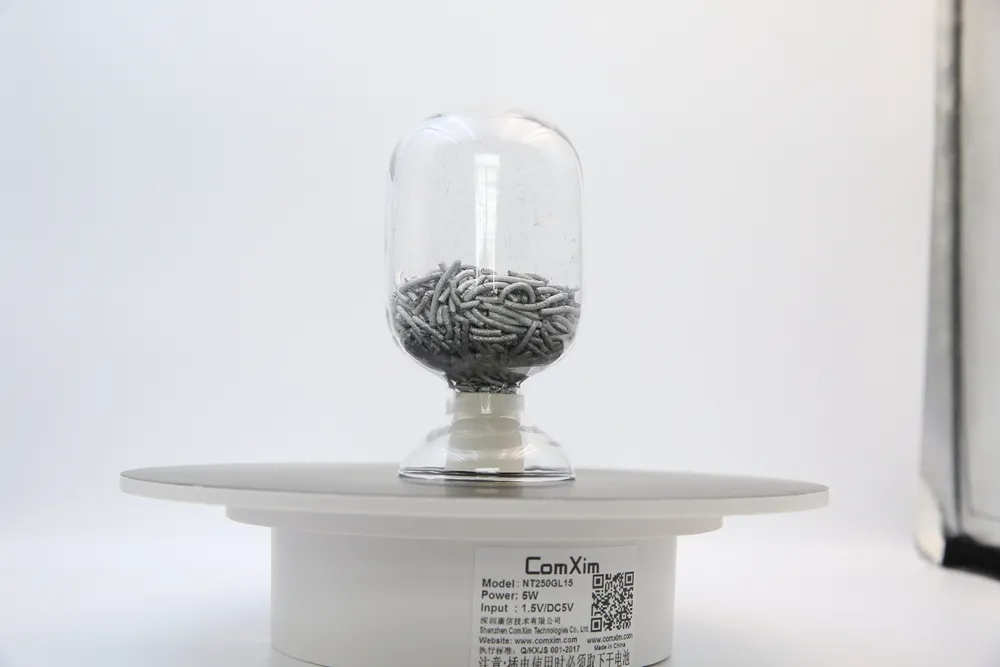

Filiform Corrosion

A kind of corrosion that is common in aluminum coatings used in structures of architecture and aerospace. Filiform corrosion also appears as a worm-like form that impacts the composition of the material, caused by several environmental factors such as temperature, humidity, and others.

Aluminum is a corrosion-resistant metal but in some instances and certain environmental factors and conditions, corrosion can be the result. The different types of corrosion can be present when using aluminum material on components, structures, and surfaces. However, with proper assessment of the challenges and conditions in its applications, aluminum can be further enhanced to eliminate the risk of corrosion and damage in its element. Some treatments and coatings can enable the protection of aluminum surfaces to reduce the formation of corrosion beyond its internal properties.

To have precise and accurate solutions in using aluminum components or materials, please have a professional help you with the specific needs of the project/s. You may also find reliable manufacturers and experts in aluminum use for higher success in its application and usage.

Aluminum Paste and Pigments Supplier and Manufacturer

Five Star Materials is one of the leading manufacturers and suppliers of aluminum paste for different industries and applications. Aluminum paste and pigments are popularly employed for enhancing surfaces and materials such as providing corrosion resistance, metallic shine, barrier protection, heat insulation, and others. It is also incorporated into substances allowing a sustainable solution that is non-toxic and suitable for a variety of purposes. When needing wholesale and bulk aluminum paste pigments for specific projects, you can contact us with the details of your inquiries. We offer competitive pricing and high-quality aluminum paste and we can ship anywhere in the world. Let us cater to the demands of your project or business needs today and deliver the utmost satisfaction with our products and services.