Manufacturers usually pick non-leafing aluminum paste for Anticorrosive Coating. It makes a thick shield that helps protect for a long time. How the particles line up and spread out is very important. This affects how well the coating stops corrosion. People need to check how strong it is, how it looks, and what weather it will face before choosing the best aluminum paste.

Principales conclusiones

- Pasta de aluminio foliada makes a bright, shiny look. The flakes float to the top. It works best for one-layer coatings. It does not last long in bad weather.

- Non-leafing aluminum paste spreads flakes all through the coating. It gives stronger protection and sticks better. It lasts longer, even in tough places.

- Use leafing paste if you want shine and only need one coat. Use non-leafing paste for strong, long-lasting protection and more layers.

- You must prepare the surface the right way. Pick the right paste for the place and job. This helps stop coating problems and keeps things safe for a long time.

- Water-based non-leafing pastes are safer for people and nature. Solvent-based leafing pastes need careful use because they give off more VOCs.

Quick Comparison

Diferencias clave

| Factor | Pasta de aluminio en hojas | Pasta de aluminio sin láminas |

|---|---|---|

| Comportamiento de los copos | Flakes rise to the top and make a shiny finish | Flakes spread out in the paint and give a soft metallic look |

| Apariencia | Very shiny, bright, and looks like a mirror | Looks softer with a satin metallic shine |

| Surface Protection | Great at blocking water and UV rays | Good at stopping corrosion |

| Resistencia mecánica | Makes a weak layer that does not stick well to others | Sticks well and works for many layers |

| Recoating | Hard to add more coats, best for one layer | Good for adding more layers and recoating |

| Aplicaciones típicas | Used for looks, like car tops, shiny trims, roofs, inks, and electronics | Used for strong coatings like car paint, building walls, roofs, planes, boats, factories, and repairs |

| Environmental Factors | Can be hurt by wetness, heat, or getting old | Stays strong in tough weather and changing conditions |

Leafing aluminum paste makes things look very shiny. The flakes float to the top of the coating. This is good when you want something to look bright and pretty. It keeps out water and sunlight well. But it does not stick to other layers. If you try to paint over it, it may not work well. Non-leafing aluminum paste spreads flakes all through the paint. This gives a softer shine. It helps layers stick together. You can use it for many coats. It also works well in rough weather.

Application Suitability

Consejo: Pick leafing aluminum paste if you want a bright, shiny look and only need one coat. Use non-leafing aluminum paste if you need strong protection, many layers, or if the surface faces bad weather.

Leafing aluminum paste is best for things that need to look nice, like car tops, shiny trims, roofs, and electronics. These things look better with a shiny surface. But it is not good if you need to paint over it or if it will get worn out. Non-leafing aluminum paste is better for cars, buildings, boats, and factories. It protects against rust and lasts a long time. It is good for places with lots of rain, heat, or things that might scratch it. If you care more about strength and protection than looks, non-leafing aluminum paste is the best choice.

Aluminum Paste for Anticorrosive Coating

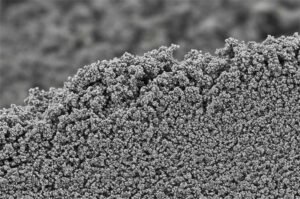

Particle Orientation

How the particles line up is very important. Pasta de aluminio foliada makes flakes lay flat on the surface. This gives a shiny, mirror-like look. The flakes pile up and reflect light. They help block water and sunlight. But, flakes can fall off as time passes. This makes the coating less strong.

Non-leafing aluminum paste acts in another way. The flakes spread out and point in many directions. This makes the coating look softer and less shiny. It helps the coating stick better to the surface. It also helps layers hold together. The mixed flakes form a thick shield. This slows down water, air, and chemicals. The coating lasts longer, even in hard weather.

Nota: Studies show that 2D nanosheets block rust better when they lay flat. If flakes stand up or point away, the shield gets weaker. Coatings with flat flakes make water and chemicals travel farther. This keeps metal safe underneath.

| Característica | Pasta de aluminio en hojas | Pasta de aluminio sin láminas |

|---|---|---|

| Particle Orientation | Flakes lie flat, parallel to surface | Flakes dispersed, random orientation |

| Surface Reflectivity | High, mirror-like | Lower, satin or matte |

| Durabilidad | Less durable, flakes may detach | Más duradero, resistente a la abrasión. |

| Barrier Effect | Strong initial barrier, weakens over time | Consistent, long-lasting barrier |

Corrosion Protection

Aluminum paste for Anticorrosive Coating keeps metal safe. It forms a shield that blocks water, air, and chemicals. Both leafing and non-leafing types stop rust. They work in different ways. Leafing aluminum paste reflects sunlight and keeps out water. It looks shiny and works well at first. But the layer can wear away if scratched or hit by bad weather.

Non-leafing aluminum paste gives stronger protection. The flakes inside make a thick, tough shield. This shield stands up to rain, scratches, and heat. The coating sticks well to metal. It does not peel or crack easily. Good sticking keeps the shield in place, even if the surface bends.

- Pasta de aluminio helps the coating bond to metal. This stops flakes and peeling.

- The thick layer blocks acids, salts, and other things that cause rust.

- Good sticking and bending help the coating resist cracks from heat or movement.

- The paste also helps stop scratches and damage.

- Por reflecting UV and infrared light, the coating ages slower and stays strong.

New aluminum pastes use tiny particles called nanomaterials. These help block UV rays and make the coating last longer. Some new pastes use water-based formulas to lower pollution. Others add special stuff to help the surface clean itself or resist dirt.

Consejo: Pick a paste that fits the weather and the surface. Non-leafing aluminum paste works best for places with lots of rain, salt, or heavy use. Leafing aluminum paste is good where looks matter most and wear is not a big problem.

Pasta de aluminio en hojas

Properties

Pasta de aluminio foliada is special because of its flake shape. The flakes line up flat on the coating. This makes a thick, shiny shield. The way the flakes sit comes from surface tension and leftover stearic acid. The smooth surface lets rain wash away dirt. This helps the coating last longer. Aluminum in this paste does not react with other things. It is safe and does not harm people. It likes oxygen and forms a thin layer on top. This layer keeps the pigment safe and stops electricity from passing through. The paste blocks light, so the primer under it does not crack. All these things make leafing aluminum paste a good pick for Anticorrosive Coating.

- Flat flakes make a strong, close barrier.

- Surface tension and stearic acid help the flakes float.

- Smooth surface lets rain clean off dirt.

- Aluminum is safe and forms a shield with oxygen.

- It blocks light and keeps primer safe.

Uses

Many businesses use leafing aluminum paste for its shiny look and protection. Car makers use it for bright roofs and trims. Builders use it for shiny walls outside buildings. Roofs and oil tanks use it because it keeps out water and looks nice. Makers also use it for building parts that need to look glossy. The paste is safe for the environment. It works well for jobs that need good looks and strong rules.

- Car paint

- Building paint

- Roof paint

- Oil tank and container coatings

- Shiny building parts

Tip: Leafing aluminum paste is best for one-layer coatings when you want a shiny look.

Ventajas e inconvenientes

| Característica | Ventajas | Desventajas |

|---|---|---|

| Apariencia | Very shiny, mirror-like finish | Shine goes away if scratched |

| Brillo | Super glossy and bright | Gloss fades with lots of use |

| Resistencia a la intemperie | Blocks UV rays, slows sun damage | Not strong in tough weather |

| Solicitud | Easy for one coat | Hard to add more coats |

| Costo | Cheap for shiny jobs | Needs extra care to last |

| Resistencia a la corrosión | Some weather protection | Water and air can get through |

| Adhesión | Sticks well for first coat | Does not stick well between layers |

| Resistencia a la abrasión | Good for light use | Flakes rub off with cleaning |

| Medio ambiente/Seguridad | Easy to recycle, lasts long | Dust can be dangerous, needs careful use |

Leafing aluminum paste gives a shiny finish and blocks some weather for one-layer jobs. But it does not stick well or last long in rough places. You must be careful when storing and using it.

Pasta de aluminio sin láminas

Properties

Non-leafing aluminum paste has aluminum flakes with oleic acid. The flakes are between 10 and 50 micrometers wide. This size helps them spread out in the coating. The paste makes a smooth metallic look that is not too bright. The flakes do not rise to the top. They stay mixed in the whole layer. This helps the coating stick well and last a long time. Non-leafing aluminum paste does not scratch or wear out easily. It can handle bad weather and strong chemicals. It works with topcoats and other layers. The paste helps the coating hold tight to metal. This gives better protection from rust. Many makers use aluminum paste for Anticorrosive Coating. It makes a strong shield that lasts in hard places.

Non-leafing aluminum paste spreads out well. This makes coatings steady and strong for a long time.

Key features of non-leafing aluminum pigments:

- Aluminum flakes with oleic acid

- Flakes are 10-50 µm wide for even spread

- Flakes mix well in the coating

- Soft, even metallic look

- Lasts long and works with topcoats

Uses

Non-leafing aluminum paste is used in many fields. It keeps surfaces safe and gives a metallic shine. Water-based non-leafing aluminum paste is used for cars, planes, buildings, and factories. It keeps its shine, sticks well, and lasts a long time. The paste also blocks UV rays and stops aging. Many companies use it for fancy coatings. It keeps things looking new and clean. Non-leafing aluminum paste is good for the earth and saves money. It still protects well from rust.

| Coating Types | Performance Benefits |

|---|---|

| Marine coatings | Stops rust, blocks UV, stands up to heat |

| Container and can coatings | Strong metallic look, keeps out rust |

| Powder coatings (hammer powder) | Hides well, sticks strong, blocks water and sun |

| Industrial coatings | Handles tough weather, lasts longer |

| Automotive refinish coatings | Lasts long, blocks UV, keeps metallic shine |

| High-end decorative coatings | Metallic shine, smooth finish, slows aging and damage |

Ventajas e inconvenientes

| Característica | Ventajas | Desventajas |

|---|---|---|

| Durabilidad | Does not scratch or wear out easily | Can cost more than leafing paste |

| Adhesión | Sticks well to metal and other layers | Not as shiny as leafing paste |

| Corrosion Protection | Makes a thick, strong shield | Shine is soft, not like a mirror |

| Resistencia a la intemperie | Handles rain, heat, and sun | Needs careful mixing to work best |

| Solicitud | Good for many layers | Water-based types may need special tools |

| Medio ambiente/Seguridad | Water-based types are safe for nature | Some types need extra safety steps |

Non-leafing aluminum paste gives strong safety and a steady look. It is good for surfaces that must last and look nice in hard places.

Performance Comparison

Resistencia a la corrosión

Manufacturers check aluminum paste for Anticorrosive Coating in many ways. They use tests for heat, cold, and salt spray. The salt spray test puts metal in salty water to see if the coating protects it. Electrochemical tests look at how well the coating stops rust by checking for holes and how much it can hold a charge.

| Testing Method | Descripción | Standard/Criteria |

|---|---|---|

| Resistencia a la temperatura | Coatings are heated to 400°C for 8 hours, then cooled. | Checks if the coating stops rust after heat, like near the sea. |

| Cold-Exposure Test | Heated to 400°C for 24 hours, then put in 23°C water for 10 minutes. | No bubbles, wrinkles, peeling, or cracks should appear. |

| Heat and Cold Cycle Test | Heats and cools the coating quickly to find problems. | Uses ASTM D2485 standard. |

| Prueba del spray de sal | Sprays salty water at 35°C to test for rust. | Uses PN-EN ISO 9227:2007. |

| Electrochemical Tests | Checks for holes, how well it blocks rust, and how much charge it holds. | Gives numbers to show how well the coating protects. |

Non-leafing aluminum paste spreads flakes all through the paint. This makes a thick shield that keeps out water, air, and chemicals. It helps stop rust from forming. Leafing aluminum paste makes a strong shield at first. But over time, the flakes can fall off. When this happens, the coating gets weaker and does not stop rust as well.

Tip: Non-leafing aluminum paste is best for places that need strong, long-lasting protection from rust and bad weather.

Durabilidad

Durability means how well the coating sticks and how it handles damage. Non-leafing aluminum paste sticks better because the flakes mix evenly. This makes it easy to add more layers and helps stop scratches. It is easier to take care of and lasts longer, even with many coats.

Leafing aluminum paste floats to the top and makes a shiny layer. This layer looks nice but does not stick well to other coats. The flakes can rub off or fall off, so it is harder to fix. It is hard to add more paint, and the shine can go away if scratched.

| Propiedad | Pasta de aluminio en hojas | Pasta de aluminio sin láminas |

|---|---|---|

| Resistencia a la corrosión | Good at first, gets weaker | Strong, lasts a long time |

| Resistencia a la abrasión | Flakes rub off easily | Stands up to scratches and wear |

| Apariencia | Very shiny, like a mirror | Soft, even metallic look |

| Durabilidad | Not very strong, hard to fix | Strong, easy to keep up |

Weather and other things can change how long the coating lasts. Leafing aluminum paste usually uses solvents, which can let out more VOCs. Non-leafing aluminum paste is often water-based, so it has fewer VOCs and is safer.

Apariencia

How the coating looks depends on the type of aluminum paste. Leafing aluminum paste floats to the top and lays flat. This makes a bright, shiny, mirror-like look. Many companies use it when they want things to look like chrome. Some types use silicon resin to help the shine last longer, even in heat.

Non-leafing aluminum paste stays mixed in the paint. This gives a smooth, even metallic look that is not as shiny. Car, boat, and factory paints use non-leafing paste for a steady look.

- Leafing aluminum paste:

- Flakes float up to the top.

- Makes a bright, mirror-like shine.

- Used for things that need to look fancy or stand out.

- Non-leafing aluminum paste:

- Flakes stay mixed in the paint.

- Makes a soft, even metallic look.

- Good for coatings that need to look the same everywhere.

Rules help make sure aluminum paste is good quality. These rules check flake size, shine, and how well it holds up. Tests like color checks and screen tests show how the coating looks in different lights and from different angles.

Note: Picking leafing or non-leafing aluminum paste changes how well it works and how it affects the earth. Making and throwing away the paste can put aluminum in the ground and water. Flakes in the air can hurt workers, so they need safety gear. Recycling and safe disposal help keep nature safe.

Laws in Europe and North America try to lower VOCs and keep workers safe. Water-based aluminum pastes follow these rules better than solvent ones. Companies must think about how well the coating works and how it affects the environment and laws.

Choosing the Right Paste

Factors to Consider

Picking the right aluminum paste for Anticorrosive Coating is important. Every project is different and needs special care. People should think about these things before they choose:

- Medio ambiente: Some coatings must handle rain, salt, or strong chemicals. Non-leafing aluminum paste works better in rough weather or factories.

- Apariencia: Leafing aluminum paste makes things look bright and shiny like a mirror. Non-leafing types give a softer, less shiny metallic look.

- Necesidades de estratificación: If you need to add more coats or fix spots, non-leafing aluminum paste is better. It lets you paint over it and sticks well.

- Durabilidad: Non-leafing aluminum paste is tougher. It does not scratch easily and lasts longer.

- Método de aplicación: Some pastes work best with a spray. Others are good for brushes or rollers.

- Regulatory Requirements: Water-based pastes follow strict rules. They let out fewer VOCs and help keep workers safe.

Tip: Always pick the paste that fits the job. Think about how it looks and how much protection you need.

Errores comunes

People sometimes make mistakes when picking or using aluminum paste for Anticorrosive Coating. These mistakes can make the coating weak and not last long.

- Ignoring Surface Preparation: Not cleaning or priming first makes the coating peel off or fail early.

- Choosing by Appearance Only: Some people pick leafing paste just for its shine, but it may not last in hard places.

- Overlooking Recoating Needs: Leafing aluminum paste is not good for many coats. This can make the coating peel or have weak spots.

- Not Checking Compatibility: Some pastes do not work well with certain primers or topcoats.

- Neglecting Environmental Rules: Using solvent-based pastes where VOC rules are strict can cause problems with the law.

Note: Plan ahead and learn what each paste does best. This helps you avoid mistakes that cost money.

| Característica | Pasta de aluminio en hojas | Pasta de aluminio sin láminas |

|---|---|---|

| Apariencia | Looks very shiny, like a mirror. | Has a soft, even metallic look. |

| Durabilidad | Keeps out water pretty well. | Sticks strong and lasts longer. |

| Impacto medioambiental | Lets out more VOCs. | Uses water, so it is safer. |

| Solicitud | Used for making things look nice. | Used for strong, protective jobs. |

Experts say you should pick aluminum paste by thinking about where and how you will use it. They can help you choose the right product, make changes if needed, and tell you how to use it safely. It is smart for makers to talk to their suppliers. This makes sure the coating works well and is safe to use.

Preguntas más frecuentes

What is the main difference between leafing and non-leafing aluminum paste?

Leafing aluminum paste makes a shiny top layer. The flakes float up and reflect light. Non-leafing aluminum paste mixes flakes all through the coating. This gives stronger protection and helps layers stick together.

Can you recoat surfaces with leafing aluminum paste?

It is hard to paint over leafing aluminum paste. The shiny layer stops new paint from sticking well. Non-leafing aluminum paste lets you add more coats and fix spots easily.

Which aluminum paste works best in harsh weather?

Non-leafing aluminum paste is better for tough weather. It makes a strong shield against rain, salt, and chemicals. This is why it is good for outside and factory use.

Is aluminum paste safe for the environment?

Water-based non-leafing aluminum pastes are safer for nature. They let out fewer VOCs and follow safety rules. Leafing pastes with solvents need more care when used or thrown away.

Does aluminum paste affect the final look of the coating?

Yes, it changes how the coating looks. Leafing aluminum paste gives a bright, mirror-like shine. Non-leafing aluminum paste makes a softer, even metallic look. Pick the one that fits how you want it to look and work.