CONECTAR

Nos pondremos en contacto con usted dentro de las 24 horas.

Para sus consultas urgentes, póngase en contacto con nosotros a través de whatsapp No: +86-18001668319

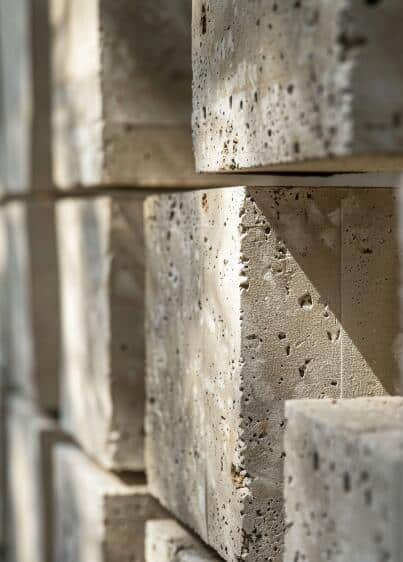

El papel de la pasta de aluminio en el hormigón ligero es principalmente como agente espumante y su rendimiento afecta directamente a la calidad y las propiedades del hormigón.

El papel de la pasta de aluminio en el hormigón ligero es principalmente como agente espumante y su rendimiento afecta directamente a la calidad y las propiedades del hormigón. A continuación se indican algunos parámetros clave que afectan al rendimiento de la pasta de aluminio:

1. Pureza: La pureza de una pasta de aluminio suele expresarse en porcentaje. Una mayor pureza suele significar que hay más ingredientes activos en la pasta y que el efecto espumante puede ser mejor. Por ejemplo, la pureza 65% de la pasta de aluminio significa que puede contener otros ingredientes además de aluminio.

2, Contenido de aluminio activo: el contenido de aluminio activo se refiere al porcentaje de aluminio en la pasta que puede participar en la reacción química y producir gas. Un mayor contenido de aluminio reactivo suele significar que se puede producir más gas durante el proceso de reacción, con lo que se forma más espuma.

3, Tamaño de las partículas: el tamaño de las partículas (D50) significa que, en determinadas condiciones, 50% de las partículas tienen un diámetro inferior a este tamaño. La pasta de aluminio con un tamaño de partícula más pequeño puede liberar gas de forma más rápida y uniforme al reaccionar con el agua, lo que ayuda a formar una estructura de espuma uniforme.

4, Contenido no volátil: el contenido no volátil se refiere a la proporción de componentes no volátiles en la pasta de aluminio después del calentamiento en condiciones específicas. Este parámetro refleja la estabilidad de la pasta de aluminio en el proceso de calentamiento, cuanto mayor sea el contenido no volátil, indica que la pasta de aluminio en el proceso de calentamiento, menor será la pérdida de componentes.

Estos parámetros determinan el rendimiento de la pasta de aluminio en el hormigón ligero, incluida su capacidad espumante, su estabilidad y las propiedades físicas del hormigón final.

1. Método de análisis químico: Separar el elemento de aluminio de la muestra disolviendo la muestra de hormigón y, a continuación, utilizar reactivos químicos para la determinación cuantitativa. Este método tiene una gran precisión, pero requiere condiciones de laboratorio profesionales y habilidades operativas.

2、Métodos de análisis espectral: incluida la espectrometría de absorción atómica (AAS), la espectrometría de emisión de plasma de acoplamiento inductivo (ICP-OES) y la espectrometría de fluorescencia de rayos X (XRF). Estos métodos pueden medir directamente el contenido de elemento de aluminio en la muestra, con características rápidas y precisas, pero necesitan instrumentación costosa y técnicos profesionales para su funcionamiento.

*Espectrometría de absorción atómica (AAS): análisis cuantitativo que utiliza la absorción de átomos de aluminio en longitudes de onda de luz específicas.

*Espectrometría de emisión de plasma de acoplamiento inductivo (ICPES): análisis cuantitativo mediante la excitación de átomos de aluminio en la muestra y la medición de los espectros característicos emitidos por ellos.

* Espectrometría de fluorescencia de rayos X: mediante irradiación de rayos X de la muestra, midiendo la intensidad de fluorescencia emitida por los átomos de aluminio tras ser excitados para determinar el contenido de aluminio.

3. Método de tamizado: En el caso del hormigón ligero que contiene una gran cantidad de polvo de aluminio, las partículas de polvo de aluminio pueden separarse del hormigón mediante tamizado y pesarse para calcular el contenido de polvo de aluminio. Este método es sencillo y rápido, pero la precisión es relativamente baja, sólo para casos específicos.

4, Método de observación microscópica: el uso de la observación microscópica de muestras de hormigón en forma de partículas de polvo de aluminio y su distribución, combinado con la tecnología de procesamiento de imágenes para el análisis cuantitativo. Este método es aplicable a la necesidad de comprender la distribución de polvo de aluminio en el hormigón.

5、Organizaciones de pruebas profesionales: Si no dispone de las condiciones necesarias para realizar las mediciones usted mismo, puede enviar las muestras a organizaciones de pruebas profesionales para que las analicen. Estas instituciones suelen contar con equipos avanzados y técnicos profesionales, y pueden proporcionar resultados precisos y fiables.

1.Densidad y peso: al aumentar el contenido de polvo de aluminio, aumenta la cantidad de hidrógeno producido por la pasta de aluminio en el hormigón, lo que provoca un aumento del número de burbujas en el interior del hormigón, reduciendo así la densidad y el peso del hormigón.

2.Resistencia: la cantidad adecuada de polvo de aluminio puede mejorar la resistencia a la compresión del hormigón, ya que las partículas de polvo de aluminio pueden rellenar los pequeños poros del hormigón, reducir la porosidad y mejorar la compacidad. Sin embargo, cuando el contenido de polvo de aluminio es demasiado alto, el exceso de burbujas puede hacer que la estructura interna del hormigón se afloje, pero reduce la resistencia.

3, durabilidad: el polvo de aluminio y otros componentes en la reacción del hormigón, pueden formar nuevos materiales cementosos, ayudan a mejorar la durabilidad del hormigón. Sin embargo, demasiado polvo de aluminio puede producir reacciones químicas desfavorables, afectando a la durabilidad.

4, Aislamiento térmico: el aumento de la estructura de burbujas mejora el aislamiento térmico del hormigón, cuanto mayor sea el contenido de polvo de aluminio, mejor será el efecto de aislamiento térmico.

5.Constructibilidad: la cantidad adecuada de polvo de aluminio puede mejorar la fluidez y trabajabilidad del hormigón, y mejorar la eficiencia de la construcción. Sin embargo, un exceso de polvo de aluminio puede hacer que el hormigón quede demasiado suelto, lo que no favorece la construcción.

La cantidad de pasta de aluminio utilizada depende de la densidad volumétrica del CAA. Si se utiliza pasta de aluminio de la misma calidad, cuanto mayor sea la densidad volumétrica del producto, menor será la cantidad de pasta de aluminio utilizada.

De hecho, podemos calcular con precisión la cantidad de pasta de aluminio utilizada basándonos en la densidad volumétrica del producto:

Basado en la fórmula de reacción de la pasta de aluminio que sustituye al hidrógeno en el agua en un entorno alcalino:

2AL 3Ca(OH)2 6H2O-3Ca.AI2O3.6H2O 3H2↑

Según las estadísticas, 2 gramos de aluminio puro metálico pueden producir 3 gramos de H2, pero en condiciones estándar, el volumen de 1 gramo de gas es de 22,41, y el peso atómico del aluminio es de 27. Por lo tanto, la producción de gas de la pasta de aluminio es:

Vo=22.4X1.241/[3/2X27]g

De acuerdo con la fórmula anterior, la producción de gas de la pasta de aluminio en diversas condiciones puede calcularse utilizando la ecuación del estado de vapor (V1/T1)=(V2/T2):

El volumen de AAC puede simplificarse en dos partes: una es el volumen aprobado del material base, y la otra es el volumen de poros formado tras la gasificación de la Pasta de Aluminio. Según el volumen de poros, se puede calcular la cantidad de pasta de aluminio:

M aluminio=V poro/(V2K)

En el tipo M aluminio-la cantidad de Pasta de Aluminio utilizada en los productos de la empresa (g/cúbico);

K--contenido de aluminio activo

El volumen de poros es igual al volumen de producto, combinado con la cantidad de materiales y sus respectivas proporciones para reducir el volumen de materias primas y agua). Sin embargo, durante el proceso de producción, la producción de gas se ve afectada por muchos factores, como los cambios de temperatura y la consistencia de la pasta. Según los cálculos teóricos, la cantidad de pasta de aluminio es imposible e innecesaria. La fábrica selecciona en base a la experiencia social y ajusta en cualquier momento. En términos generales, cuando se utiliza pasta de aluminio, la pasta de aluminio se añade en una proporción de 8/10.000 materiales secos para producir 600kg/hormigón celular cúbico.

| Nombre del producto | Contenido sólido (%) | Alúmina activa (%) | Densidad aparente | Tamaño medio de las partículas (D₅₀) | Adecuado para CAA |

|---|---|---|---|---|---|

| DEG-60 | 70% | ≥96 | 0.15 | 58-62 | <600 |

| DEG-40 | 70% | ≥94 | 0.15 | 36-42 | <500 |

| DEG-35 | 70% | ≥94 | 0.15 | 33-35 | <400 |

| DEG-25 | 70% | ≥94 | 0.15 | 25-27 | <400 |

| DEG-18 | 70% | ≥92 | 0.11 | 17-19 | <350 |

Le sugerimos que se comunique con nosotros plenamente antes de comprar, sin duda consideraremos todos los aspectos y le ofreceremos un plan de precios justo y razonable. Al elegirnos, obtendrá el mejor producto y la mejor relación calidad-precio.

Elegir el tamaño adecuado del producto le ofrece la mejor relación calidad-precio. Nuestra pasta de aluminio para ladrillo de hormigón ligero está disponible en una amplia gama de tamaños de partícula y purezas, con precios que varían según la especificación. Comunicando detalladamente sus necesidades y eligiendo el tamaño adecuado, puede obtener la mejor relación calidad-precio.

Cuanto mayor sea la cantidad comprada, menor será el precio unitario. Los pedidos al por mayor nos permiten compartir mejor nuestros costes de producción y funcionamiento, por lo que nos complace ofrecer precios con descuento por compras al por mayor.

El momento y la forma de pago que elija también afectarán al precio. Por ejemplo, pagar todo por adelantado puede resultar en un precio más favorable, ya que reduce nuestro coste de capital. Consulte con nuestro equipo de ventas la opción de pago que más le convenga.

El transporte y la logística también son factores que afectan al coste total de propiedad. Los costes de envío varían según el modo de transporte y el destino. También hay que tener en cuenta los aranceles, los seguros y otros gastos. Si calcula estos factores antes de la compra, podrá estimar con más precisión el coste total.

El proceso de producción de la pasta de aluminio aireada es crucial para determinar la calidad y el rendimiento del producto final. Este capítulo detalla el flujo de producción, las tecnologías clave y los puntos de control de cada etapa del proceso de fabricación de la pasta de aluminio aireada para ayudar a los lectores a comprender mejor la fabricación de este material crítico.

El flujo de producción de pasta de aluminio aireada (lodo)/polvo suele incluir los siguientes pasos principales:

Antes de iniciar la producción, la selección y preparación de las materias primas son cruciales. En principal Las materias primas incluyen polvo de aluminio, aditivos (como DEG, dispersantes, etc.) y otros ingredientes. La selección del polvo de aluminio suele basarse en el tamaño de sus partículas, su actividad y su pureza. El polvo de aluminio altamente activo puede generar más gas hidrógeno al reaccionar con el agua, logrando así mejores efectos de generación de gas. La selección de aditivos debe tener en cuenta su papel en la pasta de aluminio aireada, como la mejora de la fluidez y la mejora de la reactividad.

El polvo de aluminio preparado y los aditivos se mezclan en un cierta proporción. En este paso se suelen utilizar equipos de mezclado de alta eficacia para garantizar una distribución uniforme de los componentes y evitar la aglomeración. El tiempo y la velocidad de mezclado deben controlarse estrictamente durante el proceso de mezclado para garantizar una combinación suficiente de polvo de aluminio y aditivos, sentando una buena base para las reacciones posteriores.

Los materiales mezclados deben triturarse hasta alcanzar el tamaño de partícula especificado. Este paso es crucial para mejorar la actividad del polvo de aluminio. El uso de molinos de bolas u otros tipos de equipos de molienda puede reducir eficazmente el tamaño de las partículas y aumentar la superficie del polvo de aluminio, mejorando así su reactividad con el agua. Tras la molienda, los materiales también deben clasificarse para garantizar la consistencia del tamaño de las partículas y la distribución del producto.

En este paso, el polvo de aluminio molido se mezcla con agua y otros aditivos necesarios para formar la pasta de aluminio. Las condiciones de reacción en este momento (como la temperatura y la velocidad de agitación) deben controlarse para garantizar que la reacción entre el polvo de aluminio y el agua sea suficiente para generar una estructura de burbujas estable. Se puede obtener un mejor efecto de generación de gas y fluidez mediante una proporción y agitación razonables.

La pasta de aluminio aireada preparada (lodo) debe prestar atención a las condiciones ambientales durante el almacenamiento y el transporte, evitando las altas temperaturas y la humedad para prevenir la reacción prematura y el fracaso. Sus propiedades físicas y químicas deben comprobarse regularmente durante el almacenamiento para garantizar la calidad estable del producto. Por último, la pasta de aluminio debe envasarse de acuerdo con las normas para garantizar que no se produzcan fugas ni deterioros durante el transporte.

En el proceso de producción de pasta de aluminio aireada (lodo)/polvo, varias tecnologías clave tienen un profundo impacto en el rendimiento y la calidad del producto final:

La molienda de bolas es un importante tecnología para la molienda de polvo de aluminio. El proceso de molienda física puede reducir eficazmente el tamaño de las partículas del polvo de aluminio y aumentar su superficie específica. El menor tamaño de las partículas ayuda a mejorar la reactividad del polvo de aluminio, lo que le permite generar gas hidrógeno más rápidamente al reaccionar con el agua, formando así una estructura de burbujas uniforme y estable.

La tecnología de clasificación juega un importante papel a la hora de garantizar la consistencia de la distribución granulométrica del polvo de aluminio. A través de la clasificación, los polvos de aluminio de diferentes tamaños de partícula pueden separarse, mejorando la actividad y la adaptabilidad del material. Una distribución adecuada del tamaño de las partículas puede optimizar la formación de burbujas y mejorar la resistencia y el aislamiento térmico del hormigón celular.

En el proceso de preparación de la pasta de aluminio, es crucial controlar las condiciones de reacción (como la temperatura y el tiempo). Unas condiciones de reacción razonables pueden garantizar que la reacción entre el polvo de aluminio y el agua sea suficiente para generar un número adecuado de burbujas distribuidas uniformemente. La aplicación de la tecnología de control de la reacción ayuda a mejorar la estabilidad y consistencia del producto.

El rendimiento del producto puede mejorarse optimizando continuamente la formulación de la pasta de aluminio. Por ejemplo, la adición de cantidades apropiadas de ciertos aditivos puede aumentar la velocidad de reacción del polvo de aluminio y mejorar la fluidez y estabilidad de la pasta de aluminio. Además, para diferentes necesidades de aplicación, las empresas pueden desarrollar varios tipos de pasta de aluminio para satisfacer las diversas necesidades del mercado.

En la producción, el control de las condiciones ambientales (como la temperatura y la humedad) también es crucial para garantizar la calidad del producto. Especialmente en las etapas de almacenamiento y transporte, es necesario proporcionar condiciones ambientales adecuadas para evitar que la pasta de aluminio falle o se deteriore debido a los cambios ambientales.

El control de calidad es un importante a lo largo de todo el proceso de producción para garantizar el rendimiento estable de la pasta de aluminio aireada (lodo)/polvo. Las empresas suelen establecer un sistema completo de gestión de la calidad, incluyendo:

Antes de empezar la producción, todas las materias primas deben someterse a una estricta inspección de calidad para garantizar que cumplen las normas de producción. Es necesario comprobar la actividad, pureza y distribución granulométrica del polvo de aluminio para determinar si cumple los requisitos de producción.

Durante el proceso de producción, los parámetros de cada etapa (como la temperatura, la humedad, el tiempo de mezcla, etc.) se supervisan en tiempo real para garantizar que el proceso de producción esté siempre en el mejor estado. Además, los equipos de pruebas en línea pueden detectar y ajustar los problemas a tiempo para evitar la generación de productos no cualificados.

Una vez fabricado el producto, es necesario someterlo a pruebas exhaustivas de rendimiento, que incluyen indicadores como la fluidez, la generación de gas y la resistencia a la compresión, para garantizar que cumple las normas pertinentes y las necesidades del cliente. Sólo los productos que han superado las estrictas pruebas pueden ponerse a la venta en el mercado.

Preguntas frecuentes de los clientes que buscan pasta de aluminio para fábricas de ladrillos de hormigón aligerado

1. ¿Es su fábrica un Fabricante de pasta de aluminio para ladrillos de hormigón ligero?

Respuesta: Sí, somos un fabricante profesional de pasta de aluminio DEG con muchos años de experiencia en la producción y tecnología de producción avanzada.

2. ¿Cuáles son los índices de calidad de la pasta de aluminio para ladrillos de hormigón aligerado en su fábrica?

Respuesta:Los índices de calidad de la Pasta de Aluminio para Ladrillo de Concreto Liviano en nuestra fábrica son los siguientes:

Contenido en sólidos: 70±1

Tiempo de aireación retardada: 1-3 minutos

Aluminio activado: ≥92

Uniformidad granulométrica: alta

3. ¿Cuál es el precio de Pasta de aluminio para ladrillo de hormigón aligerado en su fábrica?

R: El precio de Pasta de Aluminio para Ladrillo de Concreto Liviano en nuestra fábrica depende del modelo específico y la cantidad, por favor contáctenos para una cotización detallada.

4. Cuál es la cantidad mínima de pedido de pasta de aluminio DEG en su fábrica?

R: La cantidad mínima de pedido de lodo de aluminio DEG de nuestra fábrica es de 1 tonelada, depende.

5. ¿Qué tipo de servicio post-venta puede ofrecer su Pasta de Aluminio para Ladrillos de Concreto Liviano?

Respuesta:Nuestra fábrica ofrece el siguiente servicio posventa:

Garantía de calidad del producto

Orientaciones técnicas

Seguimiento del servicio posventa

6. ¿Se puede personalizar la pasta de aluminio para ladrillos de hormigón ligero?

Respuesta: Sí, podemos personalizar la producción de pasta de aluminio DEG según los requisitos de los clientes.

En Five Star Material, entendemos que cada proyecto es único, y nuestro objetivo es proporcionar las mejores soluciones personalizadas para cada cliente.

Nos pondremos en contacto con usted dentro de las 24 horas.

Para sus consultas urgentes, póngase en contacto con nosotros a través de whatsapp No: +86-18001668319