Welcome to Five Star New Materials’ blog, your one-stop resource for premium epoxy aluminum paste and aluminum paste solutions. As leaders in the industry, we’re committed to providing you with in-depth insights into these remarkable materials and their versatile applications. In this blog post, we’ll explore the fascinating world of epoxy aluminum paste and aluminum paste, diving into their distinct compositions, properties, and how they cater to diverse industrial needs.

Epoxy aluminum paste, a standout product from Five Star New Materials, combines the strength of epoxy resin with the brilliance of aluminum pigments. It’s engineered to deliver exceptional performance in demanding environments, from heavy-duty corrosion protection to advanced decorative finishes. Our commitment to quality and Innovation ensures that our epoxy aluminum paste stands out in the market, offering you a reliable partner for your most challenging projects.

As we navigate through this blog, you’ll discover why Five Star New Materials is your go-to source for epoxy aluminum paste. We’ll break down the science behind these materials, their production processes, and the vast array of applications they serve. Whether you’re in the construction, marine, automotive, or electronics industry, our epoxy aluminum paste can be tailored to meet your specific requirements. Stay tuned as we unravel the secrets of epoxy aluminum paste and how it can elevate your projects to new heights.

Chez Five Star New Materials, nous comprenons le rôle essentiel que jouent les epoxy aluminum paste plays in high-performance applications. We specialize in producing top-tier aluminum paste, and we’re here to clarify the distinctions between general aluminum paste and our advanced epoxy aluminum paste.

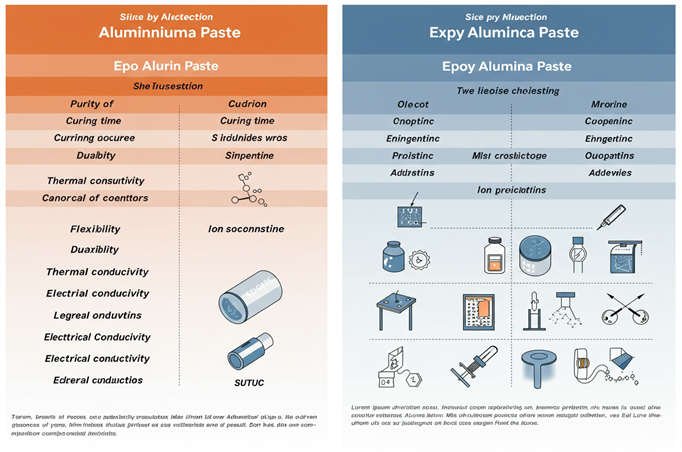

What’s the Difference Between Aluminum Paste and Epoxy Aluminum Paste?

While both are valuable materials, their compositions, properties, and applications differ significantly:

Key Components

- Aluminum Paste: We formulate aluminum paste primarily from fine aluminum powder mixed and ground with organic solvents and additives. Its simpler composition means it relies mainly on the characteristics of the aluminum powder for its effects.

- Epoxy Aluminum Paste: We create epoxy aluminum paste by incorporating aluminum pigment paste into an epoxy resin system, producing a unique coating. In addition to aluminum powder, it contains epoxy resin, curing agents, and other substances. These components interact to give epoxy aluminum paste more complex properties and versatile application features.

Functional Characteristics

- Aluminum Paste: It provides a silver-white metallic luster, strong hiding power, excellent light and heat reflection, and good decorative properties. It also offers a degree of chemical resistance, aging resistance, and flame retardancy. We recommend it for less demanding applications, such as interior decoration, light industrial products, and general protection.

- Epoxy Aluminum Paste: This material combines the strengths of both epoxy resin and aluminum powder. It leverages the high strength, strong adhesion, and chemical resistance of epoxy resin, along with the barrier effect and conductivity of aluminum powder. This combination effectively prevents corrosive media penetration, cushions substrates and delivers excellent wear resistance and mechanical properties. Its strong résistance à la corrosion allows it to withstand harsh environments. We commonly use it in heavy-duty anti-corrosion applications, such as for ships, bridges, and storage tanks.

Processus de production

- Aluminum Paste: Our production process for aluminum paste is relatively straightforward. We mix aluminum powder with organic solvents and additives in a specific proportion, then grind and disperse the aluminum powder evenly in the solvent. Le présent creates a paste with a particular viscosity and stability.

- Epoxy Aluminum Paste: The production of epoxy aluminum paste is more complex. We first mix epoxy resin, curing agents, and other raw materials in specific proportions to create the epoxy resin coating base. Then, we add aluminum powder and use exceptional dispersion and mixing processes to ensure the aluminum powder is uniformly distributed throughout the epoxy resin base. Finally, we adjust the coating’s viscosity and other performance parameters to meet construction and application requirements.

Champ d'application

- Aluminum Paste: Beyond the decorative and general maintenance industries, we also utilize aluminum paste to manufacture various aluminum silver paste coatings and inks, which find applications in the printing and packaging industries.

- Epoxy Aluminum Paste: We widely apply epoxy aluminum paste in heavy-duty anti-corrosion fields, such as protecting petrochemical equipment from corrosion, safeguarding deep-sea technical equipment, and preventing long-term bridge corrosion. It also finds use in areas requiring conductive and electromagnetic shielding properties, such as electronic equipment casings and electromagnetic shielding coatings.

What is Epoxy Aluminum Paste?

Epoxy aluminum paste typically refers to a paste with an epoxy resin base that contains aluminum pigment. It serves as a crucial raw material in the production of coatings, adhesives, and other related industries. Here’s a detailed look:

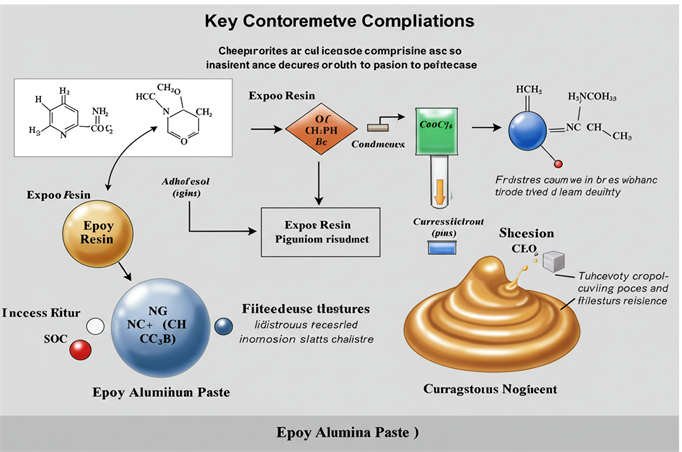

Key Components

- Epoxy Resin: This is the primary film-forming substance in epoxy aluminum paste. For example, bisphenol A epoxy resin contains multiple epoxy groups that can cross-link with curing agents, forming a tough coating with excellent mechanical properties, chemical resistance, and adhesion.

- Aluminum Pigment: We generally use flaky metallic aluminum powder, which possesses unique optical and chemical properties. It forms a dense aluminum film on the coating surface, reflecting light and blocking UV and infrared rays. It also enhances the coating’s corrosion resistance and decorative appeal.

Processus de préparation

- Raw Material Pre-treatment: We primarily pre-treat the epoxy resin, often by melting or dissolving it, to achieve an appropriate viscosity for subsequent mixing operations.

- Mixing and Dispersion: We combine the pre-treated epoxy resin with aluminum pigment and other additives in grinding equipment, such as ball mills or sand mills. Through mechanical agitation and grinding, the aluminum pigment disperses evenly in the epoxy resin, creating a fine paste.

Functional Characteristics

- Excellent Corrosion Resistance: The dense aluminum film formed by the aluminum pigment in the coating effectively blocks external moisture, oxygen, and compounds from contacting the substrate, providing excellent corrosion protection.

- Outstanding Mechanical Properties: Epoxy resin inherently possesses high mechanical strength and hardness. Cured epoxy aluminum paste coatings inherit these characteristics, offering extreme wear resistance, scratch resistance, and impact resistance.

- Exceptional Adhesion: It forms a stable bond with various substrates like metals, wood, and concrete, ensuring the coating resists peeling and flaking.

- Unique Optical Properties: It imparts a metallic texture and shimmering effect to the coating, offering high decorative value. We often use it in applications where a metallic texture is desired.

Champ d'application

- Coatings Industry: It serves as a vital raw material for epoxy anti-corrosion coatings, widely used in the anti-corrosion and maintenance of ships, bridges, petrochemical equipment, and steel structures. For example, thick-film epoxy aluminum coatings are suitable as anti-corrosion primers for boats.

- Adhesives Industry: We utilize it to prepare special-purpose adhesives, such as conductive adhesives and electromagnetic shielding adhesives. In various adhesives, aluminum pigment provides conductivity and electromagnetic shielding effects, meeting the electromagnetic compatibility requirements of electronic component packaging.

- Electronics Industry: It finds applications in manufacturing printed circuit boards and electronic shielding materials. In printed circuit boards, epoxy-aluminum paste can serve as a raw material for conductive lines that connect and disconnect circuits.

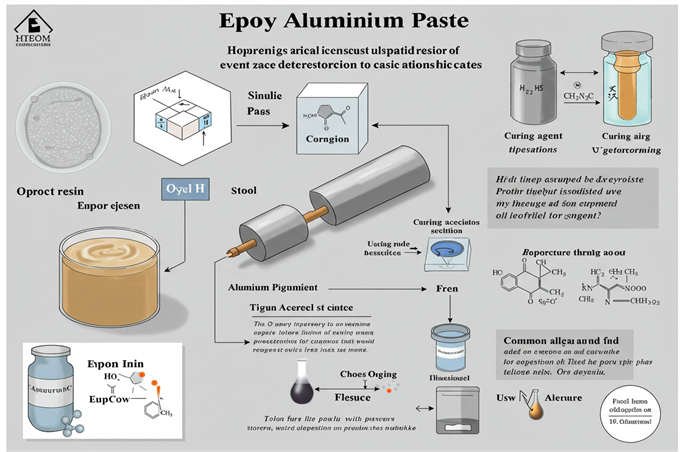

Operational Guidelines

- Conditions de stockage : Store epoxy aluminum paste in a sealed container in a calm, dry, well-ventilated area. Avoid direct sunlight and high temperatures to prevent epoxy resin curing or aluminum pigment oxidation.

- Construction Requirements: During the application process, be aware of the ambient temperature and humidity. We generally recommend temperatures between 5°C and 35°C and humidity below 85%. If construction conditions are excessively humid or the temperature is too low, it may lead to incomplete curing or defects in the coating.

- Mixing Ratio: When using epoxy aluminum paste, you must precisely prepare the ratio of epoxy aluminum paste to curing agent according to the product manual’s requirements. Le présent ensures proper drying and curing of the coating, allowing it to perform optimally.

- Application Methods: You can choose appropriate application methods based on different construction requirements, such as brushing, rolling, or spraying. Control the paint’s viscosity and pressure to achieve a uniform and smooth coating.

Which is More Common for Outdoor Use: Aluminum Paste or Epoxy Aluminum Paste?

Both aluminum paste and epoxy aluminum paste find outdoor applications, but their suitability varies:

Outdoor Use of Aluminum Paste

- Advantages: Aluminum paste offers a silver-white metallic luster, strong hiding power, and excellent light and heat reflection. It serves a decorative purpose and can protect substrates from UV radiation and moisture corrosion. Its high reflectivity can enhance structural visibility and reduce heat accumulation, improving building energy efficiency.

- Applications: We widely use it for facades, traffic signs, outdoor furniture, automotive exteriors, building exterior coatings, and outdoor advertising.

Outdoor Use of Epoxy Aluminum Paste

- Advantages: Epoxy aluminum paste combines the benefits of both epoxy resin and aluminum powder, including epoxy resin’s high strength, strong adhesion, and chemical resistance, as well as aluminum powder’s barrier effect and conductivity. It effectively prevents the entry of corrosive media and provides good cushioning for substrates, along with good wear resistance and mechanical properties.

- Applications: We widely use it in heavy-duty anti-corrosion fields, such as ships, bridges, and storage tanks.

Comparison of the Two

- Aging Resistance: Aluminum paste exhibits good aging resistance, resisting erosion from UV light, wind, and rain over the long term. However, general epoxy resin-based epoxy aluminum paste typically has poor aging resistance, and the paint film can easily delaminate and lose gloss. However, we formulate specific heterocyclic and cycloaliphatic epoxy resin-based epoxy aluminum paste for outdoor suitability.

- Decoration: Aluminum paste boasts a unique metallic texture and decorative effects, enhancing the appearance of buildings or objects. Epoxy aluminum paste offers relatively weaker decorative properties.

- Protection: Epoxy aluminum paste offers superior protective performance, providing professional protection for substrates, especially in harsh environments that require heavy-duty anti-corrosion.

Generally, both aluminum paste and epoxy aluminum paste are used outdoors but for different scenarios. If decoration and general maintenance are the primary concerns, aluminum paste sees wider application. If protection requirements are high, such as in marine, chemical, and heavy-duty anti-corrosion applications, epoxy aluminum paste is more commonly used.

Comparing Outdoor Construction Difficulty: Aluminum Paste vs. Epoxy Aluminum Paste

Let’s compare the difficulty of outdoor construction for aluminum paste and epoxy aluminum paste:

Drying and Curing Level

- Aluminum Paste: Drying speed is influenced by various factors. Solvent evaporation is generally a relatively fast process, and good outdoor ventilation accelerates solvent volatilization, thereby speeding up coating drying. However, the drying process still requires some time and is susceptible to environmental conditions, such as weather, high temperatures, and high humidity, which can slow down the drying process.

- Epoxy Aluminum Paste: It generally requires a specific time for drying and curing. Curing speed is significantly influenced by environmental factors, such as temperature and humidity, as well as the type and quantity of the curing agent. Outdoor working temperatures vary greatly, which can slow down or even prevent the curing reaction, compromising coating performance.

Environmental Adaptability

- Aluminum Paste: It demonstrates strong adaptability to outdoor environments, with good aging and corrosion resistance. It withstands erosion from UV light, wind, and rain, maintaining good stability in general outdoor conditions.

- Epoxy Aluminum Paste: It typically exhibits poor aging resistance. The epoxy groups in epoxy resin molecules can easily break down under prolonged UV exposure, leading to paint film delamination, fading, and a loss of protective function. The combination of high outdoor temperatures and oxygen accelerates the oxidative degradation of the paint film, making it brittle and hard.

Construction Operability

- Aluminum Paste: The construction process is simple. You can use spraying, rolling, or brushing methods, and the construction process is relatively easy to control. However, you must pay attention to the uniformity of the coating to avoid overly thick or thin layers.

- Epoxy Aluminum Paste: The construction process is more complex. It requires strict control of paint preparation, mixing time, strength, and other construction parameters. You must precisely control the addition and mixing of the curing agent; uneven mixing will affect coating performance.

Coating Maintenance Level

- Aluminum Paste: The coating boasts good durability and stability, resisting cracking and peeling, but it may require maintenance in harsh environments.

- Epoxy Aluminum Paste: The coating is prone to issues such as cracking and peeling, especially in outdoor environments where mechanical impact, temperature fluctuations, and other factors can cause various problems. Maintenance costs and difficulty are also higher.

Recommended Outdoor Application Methods for Aluminum Paste and Epoxy Aluminum Paste

Here are the recommended application methods for aluminum paste and epoxy aluminum paste when performing outdoor construction:

Aluminum Paste

- Substrate Preparation: We clean the coating surface, removing oil, dust, rust, and other impurities to ensure it’s clean, dry, and smooth. You can use manual or mechanical polishing to remove rust and old coatings. For concrete substrates, ensure they are thoroughly dry and that their moisture content meets the requirements; we generally recommend a moisture content of not more than 8%.

- Construction Conditions: During application, the operating temperature should be between 5°C and 35°C, and the humidity should be below 85%. Avoid construction during adverse weather conditions, such as rain, snow, fog, or strong winds, to prevent surface contamination or water vapor condensation, which can harm coating adhesion and drying effects.

- Application Methods: Common application methods include brushing, roller coating, and spraying. Brushing is suitable for small areas, offering easy and flexible operation, as well as better control over coating thickness. Roller coating is efficient for large-area applications, ensuring uniform coating distribution. Spraying enables aluminum paste to cover the coating surface more evenly, particularly for complex shapes or irregular surfaces, thereby providing better coating uniformity and integrity.

- Coating Control: During application, ensure the coating is uniform and avoid sagging or missed spots. We generally recommend applying 2-3 coats to ensure sufficient fullness and hiding power. Determine the interval between each coat based on the coating’s drying condition, typically 2-4 hours, applying the next coat only after the previous one has cured.

Epoxy Aluminum Paste

- Substrate Preparation: For metal substrates, we recommend sandblasting or shot blasting to achieve Sa2.5 or St3 grade surfaces, which enhances coating adhesion. For concrete substrates, ensure they are clean and free of honeycomb voids and dust. You can use grinding and polishing methods to clean and repair the substrate. For specific concrete substrate requirements, you may also need to apply a sealing primer to improve coating adhesion and anti-corrosion performance.

- Construction Conditions: We generally recommend an operating temperature for construction between 10°C and 30°C and humidity below 80%. Low temperatures can significantly impact the curing rate of epoxy resin, potentially leading to incomplete curing. If the temperature is too high, the solvent may evaporate too quickly, resulting in issues such as pinholes and bubbling. We also ensure that construction is not hindered by adverse weather.

- Paint Preparation: Follow the manufacturer’s provided mixing ratios and operating procedures strictly. Mix the epoxy resin, aluminum powder, curing agent, and other components thoroughly until a uniform mixture is achieved, ensuring that all ingredients are completely dispersed. The mixed paint should exhibit good fluidity and application performance.

- Application Methods: You can use brushing, rolling, or spraying. For small components or localized repairs, brushing is a common choice. For large-area construction, roller coating and spraying are more efficient, ensuring uniformity and consistency of the coating.

- Coating Control: During application, pay attention to controlling the coating thickness. We generally recommend that the thickness of each coating does not exceed 50 μm; excessively thick coatings can lead to incomplete curing and uneven surfaces. You usually need to apply multiple coats to achieve the desired total coating thickness, with an interval between each coat depending on the paint’s curing situation, typically 6-24 hours.

- Curing and Protection: After application, take appropriate protective measures to prevent the coating from being affected by external factors during the curing process, such as avoiding contact with water or chemicals. Le présent ensures the coating fully cures and performs its protective function.

Five Star New Materials takes pride in being at the forefront of epoxy aluminum paste Innovation. Our products are meticulously crafted to deliver outstanding performance, durability, and aesthetic appeal. As we’ve explored in this blog, epoxy aluminum paste isn’t just a material—it’s a solution that addresses the complexities of modern industrial demands.

We’ve highlighted the diverse applications of epoxy aluminum paste, ranging from safeguarding critical infrastructure, such as bridges and ships, to enhancing the functionality of electronic devices. Our commitment to excellence is reflected in every batch we produce, ensuring that our customers receive a product that stands the test of time.

At Five Star New Materials, we understand that your projects require materials that perform under pressure. That’s why we continuously invest in research and development to push the boundaries of what epoxy aluminum paste can achieve. We’re not just selling a product; we’re offering a partnership built on trust, quality, and Innovation.

If you’re looking for an epoxy aluminum paste that meets the highest standards, look no further than Five Star New Materials. We invite you to explore our comprehensive product range and experience the difference that superior quality and dedicated service can make.

For more information on how our epoxy aluminum paste can benefit your projects, please visit our website or contact our expert team. Let’s build a brighter, more durable future together with Nouveaux matériaux cinq étoiles.

Do you have specific project requirements for epoxy aluminum paste? We’re here to help you unlock its full potential!