You must watch each step when using aluminium paste paints. Small changes in particle size or resin compatibility can make big changes. These changes affect how the paint looks and works. Studies show even small shifts can change color and gloss. This can change how customers view your product. Aluminium paste gives coatings a shiny, metallic look. It also makes them stronger. Careful work helps you get good and nice results every time.

Principaux enseignements

- Pick the right aluminum paste for your project. Different grades and types change how the paint looks and lasts.

- Mix aluminum paste with care. Use low-shear mixers to keep the flakes whole and get a smooth finish.

- Store paint the right way to stop oxidation. Keep it in a cool, dry spot and use sealed containers to keep it good.

- Test small batches before making big mixes. This helps you find problems with color or texture early.

- Follow safety rules when using aluminum paste. Wear protective gear and make sure there is good airflow to keep everyone safe.

Aluminium Paste Selection

Picking the right aluminium paste is very important. You need to choose one that fits your project. This helps you get the look and strength you want.

Grade & Type

There are many grades and types of aluminium paste. Each one gives a different result. Some make the paint sparkle. Others make it smooth and shiny. The table below lists some common products and their features:

| Nom du produit | Propriétés |

|---|---|

| STAPA® METALLUX 1000 | Tinting strength, hiding power, and sparkle effect. High brilliance. |

| STAPA® METALLUX 1500 | Highly brilliant silverdollar, strong metallic effect, unique hiding power. |

| STAPA® METALLUX 2000 | Standard silverdollar, narrow particle size distribution. |

| STAPA® METALLUX 3000 | Silverdollar, high brilliance, color purity, dark flop. |

| STAPA® METALLUX 8000 | Fine, narrow particle size for clear color shades. |

| STAPA® METALLUX 9000 | Silky gloss grades, very bright and fine, low flop for silky gloss and bright color shades. |

| STAPA® SILVERSHINE 400 | Latest Silverdollar technology. |

| STAPA® NDF | Non-degrading flakes, high shear stability, fineness for clear color shades. |

| Leafing Pigments | High surface tension, float on wet film, orient on the surface. |

| Non-Leafing Pigments | Completely wetted, spread evenly throughout the paint film. |

| Particle Shape | Flake form varies from irregular cornflakes to round silverdollars. |

| Taille des particules | Varies by product and milling, changes optical properties. |

You should know about leafing and non-leafing types. Leafing aluminium paste floats to the top of the paint. This makes the finish shiny like a mirror. But it can peel off more easily. Non-leafing aluminium paste spreads through the paint. It gives a smooth look and sticks better. This makes it last longer.

| Type | Apparence | Durabilité |

|---|---|---|

| Leafing Aluminum | High reflectivity, chrome-like | Poor adhesion, flake detachment |

| Non-Leafing Aluminum | Uniform, strong adhesion | High durability, stable |

Conseil : If you need a tough finish, like for outdoor or marine paints, use non-leafing aluminium paste. It lasts longer and stays strong.

Application Needs

Think about where and how you will use the paint. For decoration, you may want a bright, sparkling look. For marine or water-borne paints, pick a paste that works with water-based binders. Always check if the aluminium paste fits your paint.

- Make sure the paste matches your paint, especially for water-borne systems.

- Test a small batch before making a big mix.

- Mix the paste with water-based binders and watch for changes or gas bubbles.

- Use passivated aluminium paste in water-based paints. This stops dangerous reactions and keeps the paint safe.

- Choose water-borne, low-VOC pastes for a cleaner, safer product.

Remarque : If you use the wrong aluminium paste, you might see bubbles, bad color, or safety problems.

Supplier Standards

Always buy aluminium paste from trusted suppliers. Good suppliers test their products and follow rules. Look for signs of quality:

- Third-party testing for product safety and performance.

- Certifications from groups that set industry standards.

- Proof that the supplier meets international rules, like MIL-STD-171 for metal finishes.

Alert: If a supplier cannot show certifications or test results, find another source. Quality and safety are important for every project.

Particle Size & Treatment

Size Distribution

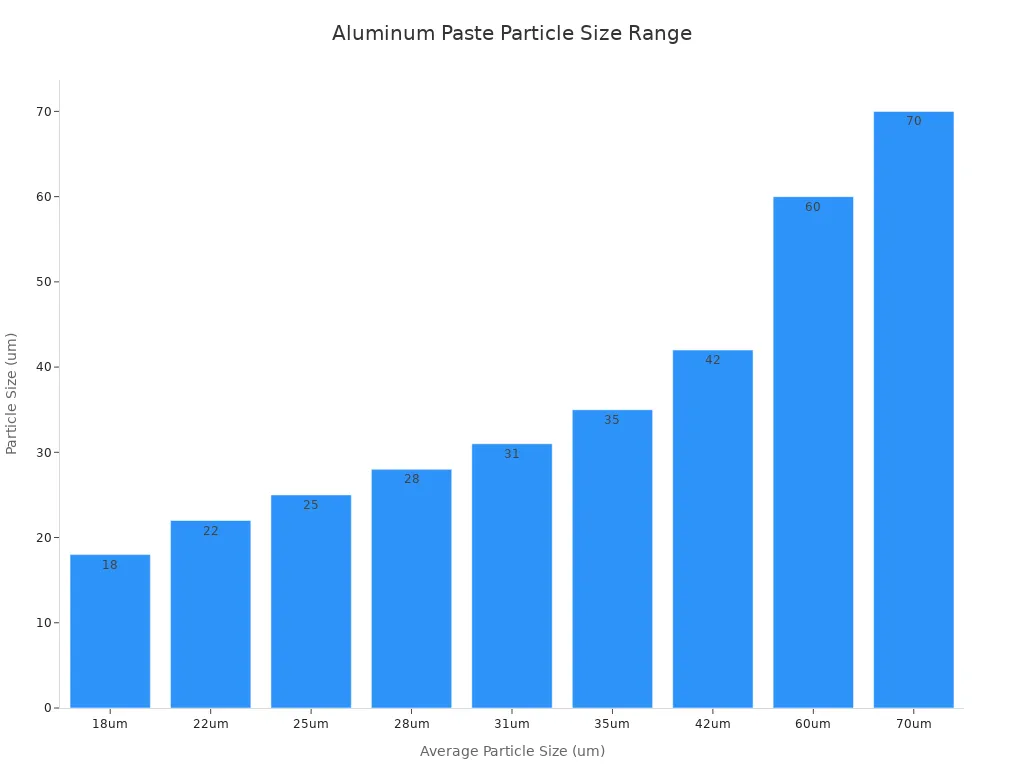

You must watch the particle size of aluminium paste. The size changes how the paint looks and works. If the particles are all close in size, the paint looks smoother. It also shines more. Big particles make the paint look glossier and reflect more light. Small particles spread light out. This makes the paint look softer and less shiny.

Here is a table that shows the usual particle sizes for high-performance paints:

| Average Particle Size (D50) |

|---|

| 18um |

| 22um |

| 25um |

| 28um |

| 31um |

| 35um |

| 42um |

| 60um |

| 70um |

Conseil : For a very shiny paint, pick aluminium paste with a narrow particle size range.

- A narrow particle size range gives a smoother and shinier finish.

- Big particles make the paint glossier and reflect more light.

- Small particles make the paint look softer and scatter light more.

Surface Coating

Special surface treatments can help aluminium paste work better. These treatments help stop corrosion and make the paste last longer. Some ways to treat the surface are adding silica, using polymer coatings, or using inorganic compounds.

| Surface Treatment Method | Description |

|---|---|

| Silica Modification | Helps flakes stick to the polymer and line up right. It also blocks things that cause rust. |

| Polymer Coatings | Protects against rust and stops gas bubbles in water-based paints. |

| Inorganic Compounds | Adds more protection from rust and lets you use the paste in more ways. |

Surface treatments do more than stop rust. They help the flakes spread out in the paint. This makes the paint look better and last longer.

- Passivation treatment makes aluminium pigments resist rust and look better.

- It helps the process and is better for the environment.

- It keeps the paint stable and reliable in many uses.

- Treated flakes spread out and line up better in the paint.

- This gives a steady barrier.

- It helps protect the paint from rust.

Remarque : The right surface treatment keeps your paint shiny and strong, even in hard conditions.

Agglomeration Control

Agglomeration is when particles stick together and form lumps. You do not want lumps because they ruin the smooth look and shine. Many things can cause lumps, but you can stop them if you are careful.

- Moisture: Too much or too little water can make lumps. Keep the moisture just right.

- Mixing: How you mix the paste matters. Change the speed and movement to keep particles apart.

- Mixing time: Mixing too long or too short can make lumps. Find the best time for your process.

- Material: Some pastes lump more than others. Pick materials that work well together.

Alert: Always check how you mix and store your paste. This helps stop lumps and keeps your paint looking great.

If you control particle size, use good surface treatments, and stop lumps, your aluminium paste paint will work well every time.

Dispersion & Mixing

Equipment Choice

You need to pick the right equipment for mixing. Always add the aluminum silver paste at the last stage of your mixing process. This step protects the special coating on the paste. If you use high-speed mixers or dispersing disks, you might damage the paste. Instead, choose low-shear mixers. These mixers stir gently and keep the paste flakes in good shape. When you use the right equipment, you get a smooth, shiny finish and avoid problems with the paint.

Conseil : Use a paddle mixer or a slow-speed stirrer for best results. Avoid high-shear tools that can break the flakes.

Mixing Parameters

How you mix matters as much as what you mix. The speed and time you use will change how well the paste spreads out. Here are some important points:

- Stirring at 1,000 RPM for 10 minutes helps you get a uniform mix.

- Finer particles mix faster and stay suspended longer.

- Coarser particles settle more quickly, so you need to watch them closely.

- A 7μm paste can reach a 95% dispersion rate, while a 70μm paste only gets to 85%.

If you want your paint to look even and bright, always check your mixing speed and time. Try different settings with small batches to find what works best for your system.

Sedimentation Prevention

Sedimentation happens when the paste settles at the bottom of the container. You can stop this by using the right additives and storage methods. Here are some ways to prevent sedimentation:

- Add binders to help the paste stick and stay mixed.

- Use leveling agents for a smoother surface.

- Try anti-settling agents like Lencolo 1110 to keep the paste from sinking.

- Store your paint in a cool, dry place.

- Check the paint often for changes in texture or color.

- Use strong, sealed containers to stop leaks or air from getting in.

Remarque : Regular checks and the right additives keep your paint stable and easy to use. Good storage keeps your product safe and ready for the next job.

Environmental & Storage Control

Oxidation Prevention

You must keep your paint safe from oxidation. Oxidation can make your coating lose its shine and strength. Store your paint in a cool and dry place. Make sure the humidity stays under 65%. This helps stop water from touching the metal flakes. Always use the original sealed container. This keeps out air and moisture. Good airflow in your storage area stops solvent vapors from building up. Handle your paint with care. Do not shake or stir it too much. Use the oldest paint first. This is called FIFO, which means First In, First Out. It helps you use paint before it gets too old.

Conseil : Keep storage rooms cool and dry. Check containers often for leaks or damage.

Temperature & Humidity

Temperature and humidity can change how your paint works and looks. Too much heat or moisture can cause clumps, dullness, or even fire. Keep your storage room between 59°F and 77°F (15°C to 25°C). Do not let it get hotter than 104°F (40°C). Keep humidity low to stop clumping and make mixing easy.

| Environmental Factor | Impact on Stability |

|---|---|

| Température | High heat can cause fire. Very cold can make the coating cure too fast. |

| Humidité | High humidity makes clumps and ruins mixing. |

| Moisture | Paint soaks up water, which hurts quality. |

| Moisture Exposure | Too much water can break the coating and cause rust. |

Alert: Quick changes in temperature or humidity can make your paint go bad faster.

Container Selection

Le right container keeps your paint safe and fresh. Use stainless steel or galvanized iron drums for long storage. Anti-static plastic drums are also good. Never use glass or regular plastic containers. These can break or let in air and water.

| Container Material | Recommendation |

|---|---|

| Metal Drums | Stainless Steel, Galvanized Iron |

| Anti-static Plastic Drums | Good for storage |

| Glass or Ordinary Plastic | Do not use |

Remarque : Always close containers tightly after using them. This keeps your paint safe and ready for next time.

Compatibility & Quality Control

Resin & Solvent Match

You must use the right resin and solvent with your pâte d'aluminium. This helps stop problems like weak sticking, bubbles, or uneven shine. If you pick the wrong binder or primer, the metallic look can change. Some resins or mineral spirits might make the paste separate or settle. Always check if everything works well together before making a big batch.

| Fonctionnalité | Description |

|---|---|

| Résistance aux intempéries | Color stays bright in sunlight and outside. |

| Strong Adhesion | Sticks well to coatings, plastics, and inks. |

| Résistance à la corrosion | Stops rust and makes it last longer. |

| Smooth Finish | Makes the coating flat and even. |

Conseil : Try a small test first to see if your resin and solvent work with the pâte d'aluminium.

Color Consistency

You want your paint to look the same every time you use it. Keeping color the same is important for trust and quality. Here are some steps to help keep your color steady:

- Pick a supplier with a strong quality system, like ISO 9001.

- Check each batch with tools like particle size analyzers and color testers.

- Store materials in sealed containers and use the oldest ones first.

Checking often helps you find changes early and keeps your paint looking good.

Safety Protocols

Using pâte d'aluminium safely keeps you and your team safe. You should follow these règles de sécurité:

| Safety Protocols | Description |

|---|---|

| Inflammabilité | Keep away from fire and sparks. |

| Skin and Eye Contact | Wear gloves, goggles, and protective clothes. |

| Inhalation | Use good airflow and keep the paste wet. |

| Conditions de stockage | Store in cool, dry, and airy places. |

| Dust Generation | Do not make dust when using it. |

| Training | Teach workers how to use it safely and what to do in emergencies. |

| Disposal Regulations | Follow local rules for throwing away waste and water. |

Alert: Never skip safety steps. Training and the right gear keep everyone safe.

Technical Support

You can get help from your pâte d'aluminium supplier. Many suppliers give technical support for different needs. They help you pick the right product, answer questions, and fix problems. Some suppliers work with car paints and offer high shine or special surface treatments. Others have grades for plastics, printing, or lightweight concrete.

| Fonctionnalité | Description |

|---|---|

| Market Focus | Used in cars, coatings, plastics, and printing. |

| Luminosité | Very shiny and strong silver color. |

| Particle Sizes | Many sizes to choose from. |

| Surface Treatments | Different treatments for better results. |

| Technical Support | Help with picking products and solving problems. |

Remarque : Good technical support helps you get the best results and fix problems fast.

You can get the same good results if you follow these main steps: First, mix the paste well so the metallic paint looks smooth. Next, pick the right solvent so you do not get bad reactions. Then, make sure the flakes line up flat to get the most shine.

You must know a lot about how to mix and store the paste. Learn about how the paste spreads, the size of the particles, and how to keep it safe. Ask your supplier for help if you have questions.

A checklist can help you do a good job and make your work better:

| Supplier Attribute | Description |

|---|---|

| Quality Focus | Puts quality first, delivers on time, gives good service |

| Technology Use | Uses the latest technology |

| Continuous Improvement | Always making products better |

Keep learning about the best ways to use these paints to get great results.

FAQ

What makes aluminum paste paint look metallic?

Aluminum flakes in the paste reflect light. You see a shiny, metallic effect because the flakes line up flat in the paint. This gives your surface a bright, mirror-like look.

Can I use aluminum paste in water-based paints?

Yes, you can use special passivated aluminum paste in water-based paints. This type stops unwanted reactions. Always test a small batch first to check for bubbles or color changes.

How do I stop aluminum paste from settling?

You should stir the paint before use. Add anti-settling agents if needed. Store the paint in a cool, dry place. Use sealed containers to keep the paste mixed and ready.

Is aluminum paste paint safe to use?

Vous devez suivre règles de sécurité. Wear gloves and goggles. Keep the paste away from fire. Work in a space with good airflow. Always read the safety data sheet before starting.

Why does my metallic paint look dull?

Dull paint can happen if you use the wrong particle size or mix too fast. Check your mixing speed and time. Make sure you use the right aluminum paste for your paint system.