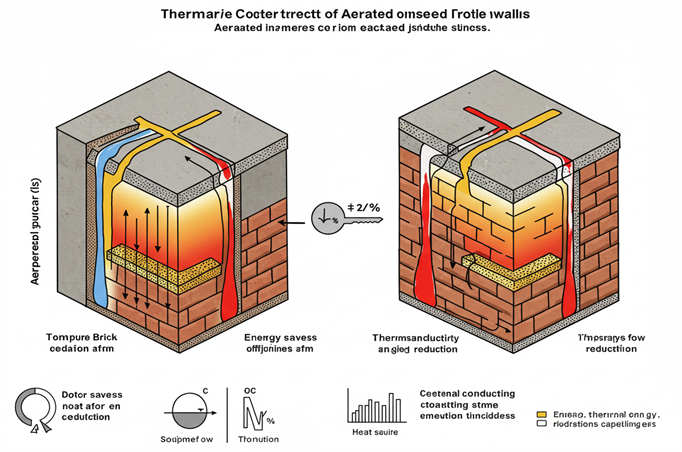

Aluminium Paste & Powder (APP) is a key aerating agent for producing lightweight aerated concrete. It reacts with alkaline substances to release hydrogen, creating a porous structure that enhances thermal insulation, soundproofing, and construction flexibility. Ideal for reducing building weight and improving earthquake resistance.

Aluminium Paste & Powder (APP) is a crucial aerating agent in producing AAC blocks. It reacts with alkaline substances to release hydrogen gas, forming a lightweight, porous structure. Below are the key aspects:

In an alkaline environment (e.g., Ca(OH)₂), Aluminium Paste & Powder reacts with water to produce hydrogen gas:

2Al+3Ca(OH)2+6H2O→3CaO⋅Al2O3⋅6H2O+3H2↑

This reaction creates uniformly distributed pores within the slurry, reducing the final product density to 500-700 kg/m³—only one-fifth of conventional concrete.

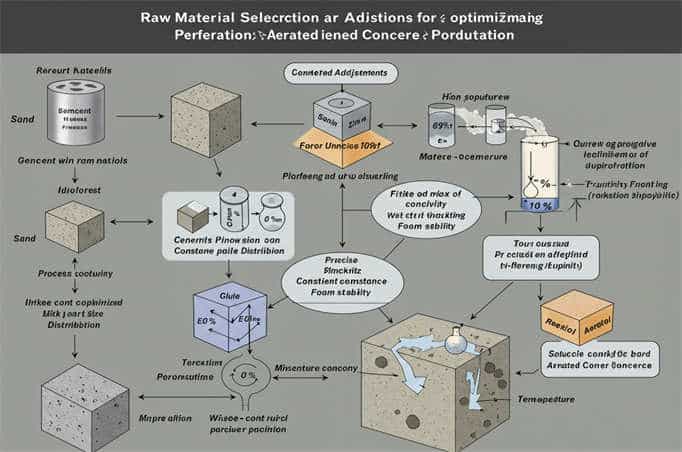

The size and distribution of pores directly determine AAC’s insulation and soundproofing properties. To achieve an ideal pore structure, the aluminum particles must have a suitable fineness (≤3% residue on a 0.075mm sieve) and a high active aluminum content (≥85%).

2.2 Technical Specifications (Based on JC/T407-91 Standard)

| Type | Solid Content (%) | Fineness (0.075mm Residue) | Gas Evolution Rate (%) | Active Aluminum (%) |

|---|---|---|---|---|

| Oil-based GLY-75 | ≥75 | ≤3.0 | ≥90 | ≥90 |

| Water-based GLS-65 | ≥65 | ≤3.0 | ≥85 | ≥85 |

| Characteristic | Aluminum Paste (Water-based) | Dry Aluminum Powder |

|---|---|---|

| Production Process | Wet grinding, no need for degreasing | Dry grinding, requires degreasing |

| Safety | No dust explosion risk | Flammable and explosive, requires nitrogen protection |

| Ease of Use | Directly added to slurry, good dispersion | Requires pre-degreasing treatment |

| Environmental Impact | Low pollution, easy wastewater treatment | High energy consumption, more pollution |

Below are key testing methods and technical requirements based on industry standards and practical applications:

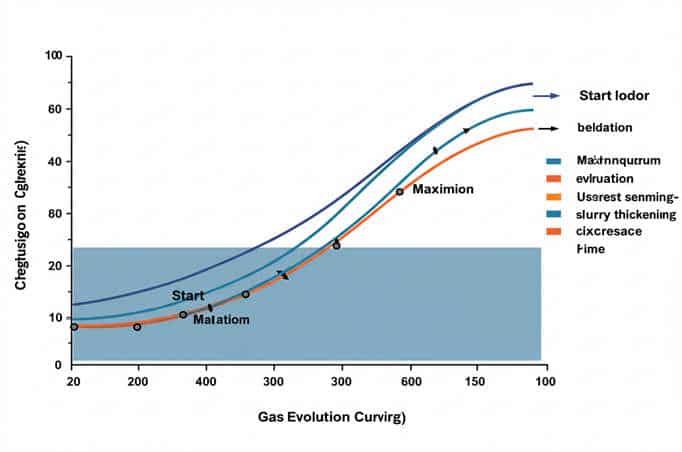

Aluminium Paste & Powder must aerate at a rate that aligns with slurry thickening:

Maintain slurry temperature at 40-60°C. Excessive heat accelerates aeration, risking uncontrolled expansion, while low temperatures slow aeration, leading to uneven pore distribution.

Fiver Star New Materials ensures optimal concrete quality, enhancing thermal efficiency, mechanical strength, and construction adaptability by fine-tuning aeration parameters.

Nous vous suggérons de communiquer avec nous avant d'acheter, nous prendrons en compte tous les aspects et nous vous proposerons un plan de prix juste et raisonnable. En nous choisissant, vous obtiendrez le meilleur produit et le meilleur rapport qualité-prix.

Choosing the right size of product gives you the best value for money. Our Metal Flash Aluminum Silver Paste is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

Plus la quantité achetée est importante, plus le prix unitaire sera bas. Les commandes en gros nous permettent de mieux répartir nos coûts de production et d'exploitation, c'est pourquoi nous sommes heureux de proposer des prix réduits pour les achats en gros.

Le moment et le mode de paiement que vous choisissez ont également une incidence sur le prix. Par exemple, un paiement anticipé intégral peut donner lieu à un prix plus favorable, car il réduit le coût du capital. Veuillez discuter de l'option de paiement la plus appropriée avec notre équipe de vente.

Le transport et la logistique sont également des facteurs qui influencent le coût total de possession. Selon les modes de transport et les destinations, les frais d'expédition varient. Les droits de douane, l'assurance et d'autres coûts doivent également être pris en compte. En calculant ces facteurs avant l'achat, vous pouvez estimer le coût total avec plus de précision.

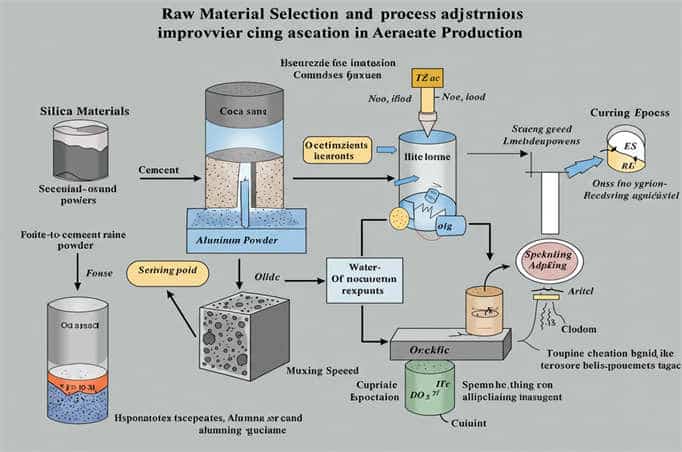

At Five Star Materials, our Aluminium Paste & Powder for AAC produced in a delicate and rigorous process. Below is our basic production process:

Nous achetons des matières premières de grande pureté auprès de fournisseurs de confiance afin de garantir la qualité de nos produits dès la source.

La matière première est broyée pour transformer les blocs d'aluminium en minuscules particules en vue d'un traitement ultérieur.

La poudre d'aluminium broyée est mélangée à nos solvants et additifs spécialement formulés, puis mélangée à grande vitesse. Cette étape est très importante car elle détermine la stabilité de la pâte d'aluminium et la forme des particules.

Après le broyage, la pâte d'aluminium passe par un système de filtration pour éliminer les éventuelles impuretés. Notre équipe de contrôle de la qualité effectue ensuite une série de tests sur le produit, tels que la taille des particules, la brillance, le toucher métallique, etc., afin de confirmer que le produit répond à nos normes de qualité élevées.

Les produits qui ont passé des tests rigoureux sont soigneusement emballés et stockés dans nos entrepôts, prêts à être expédiés à nos clients.

Veuillez noter qu'il s'agit d'un processus de production de base et que le processus exact peut varier en fonction des exigences spécifiques du produit. Chez Five Star Materials, nous prenons le contrôle de la qualité très au sérieux et nous nous assurons que nos produits répondent à nos normes de qualité strictes à chaque étape du processus de production.

Chez Five Star Material, nous comprenons que chaque projet est unique et notre objectif est de fournir les meilleures solutions personnalisées à chaque client.

Nous vous contacterons dans les 24 heures.

Pour toute demande urgente, veuillez nous contacter par whatsapp : +86-18001668319