Black aluminum powder, a specially treated aluminum powder with a black or dark gray appearance, is widely used in various industries due to its unique properties and versatile applications. This guide explores its characteristics, applications, and proper usage methods, providing valuable insights for professionals and enthusiasts.

Black aluminum powder, a specially treated aluminum powder with a black or dark gray appearance, is widely used in various industries due to its unique properties and versatile applications. This guide explores its characteristics, applications, and proper usage methods, providing valuable insights for professionals and enthusiasts.

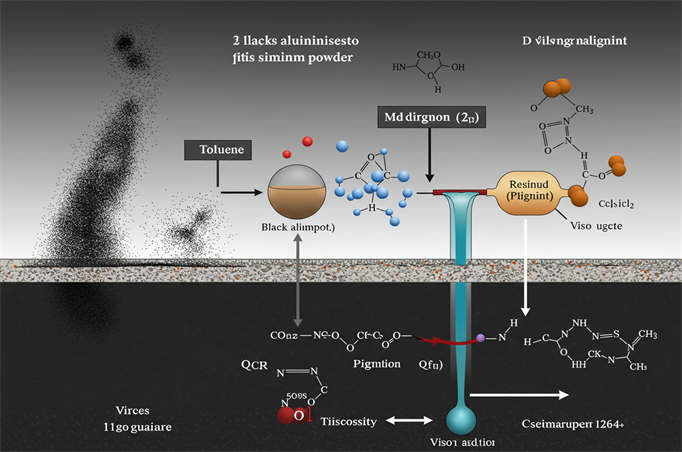

Black aluminum powder is a specially treated aluminum powder, typically covered with an aluminum oxide film on its surface. This oxide layer enhances the powder’s stability and antioxidant properties, giving it a black or grayish-black appearance.

In practical applications, black aluminum powder possesses unique characteristics and versatile uses. It is widely used across industries like coatings, inks, composite materials, aerospace, chemicals, metallurgy, refractory materials, anti-corrosion coatings, fireworks, and bamboo industries. For example, black aluminum powder is used in coatings to create metallic textured black paints, enhancing products’ aesthetic and protective properties. In composite materials, it is a reinforcing material to improve strength and wear resistance.

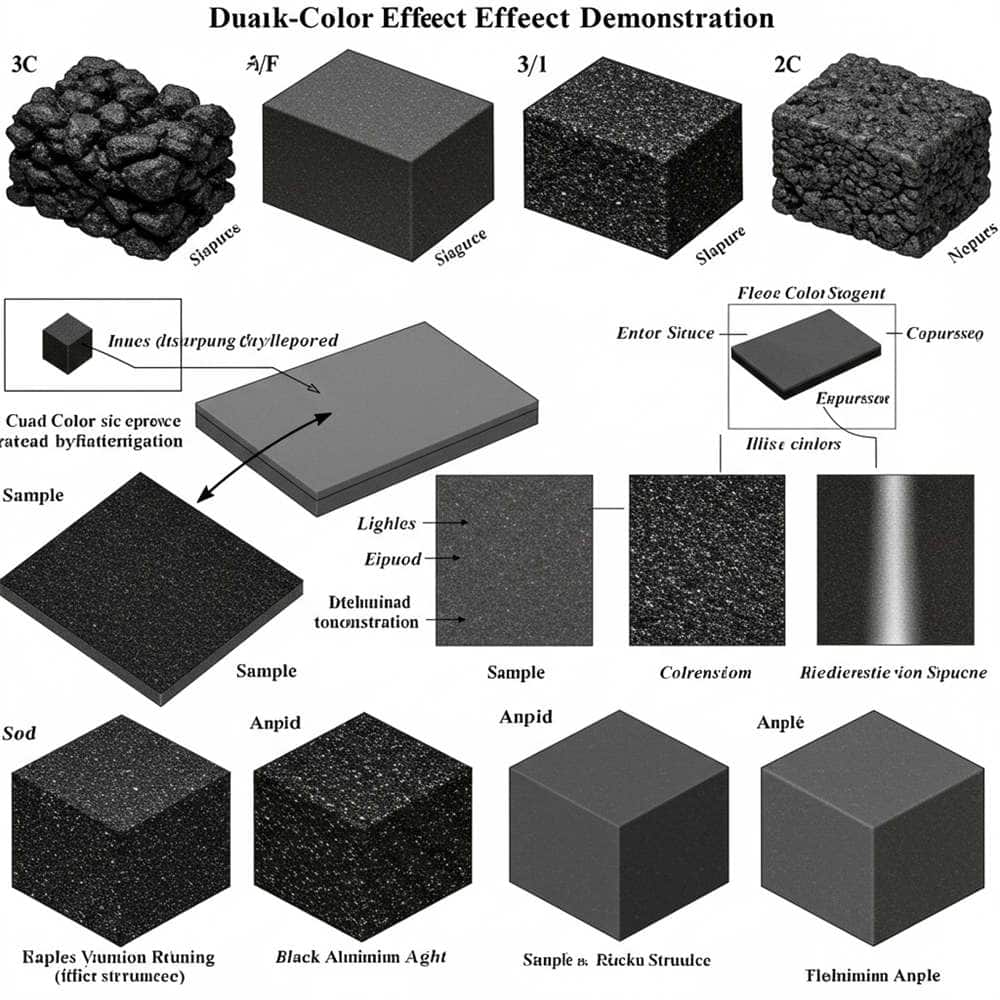

Additionally, black aluminum powder exhibits a “dual-color effect,” where its gloss and color depth change based on the incident angle and viewing angle when mixed with transparent pigments. This feature makes it especially valuable for special coatings and decorative materials.

It is important to note that specific safety and operational protocols must be followed when using black aluminum powder to ensure its flexible application and safe handling.

Black aluminum powder is commonly used in coatings. Below are some popular methods:

By following these methods, black aluminum powder can effectively be used in coatings, offering unique decorative and functional benefits.

To achieve the desired smoothness, the amount of aluminum powder should be adjusted based on the specific requirements and the coating system, typically ranging from 1% to 10%. Here are some guidelines:

By following this approach, you can effectively adjust the amount of aluminum powder to achieve the ideal smoothness.

The ideal amount of aluminum powder for achieving the desired gloss in coatings typically falls between 1% and 10%, depending on specific requirements and the coating system used. By understanding the relationship between aluminum powder usage and gloss and considering factors like particle size and dispersion, you can effectively adjust the Dosage to reach the optimal gloss for your coating projects.

Unlock Premium Performance with 5Star Materials’ Black Aluminum Powder

🌟 Key Takeaways at a Glance

| Property | Benefit | Ideal For |

|---|---|---|

| Enhanced Stability | Oxide layer ensures oxidation resistance & longevity | Aerospace, Automotive Coatings |

| Dual-Color Effect | Dynamic color shifts for eye-catching finishes | Decorative Materials, Luxury Goods |

| Superior Coverage | High hiding power reduces application layers | Industrial Paints, Anti-Corrosion |

| Customizable Smoothness | Adjust particle size (1-10% dosage) for matte to high-gloss finishes | Textured Coatings, Consumer Electronics |

| Multi-Industry Versatility | Compatible with water-based/solvent systems, composites, refractories | Construction, Marine, Energy |

Transform Your Coatings with Industrial-Grade Black Aluminum Powder At 5Star Materials; we specialize in delivering high-performance black aluminum powder engineered to elevate your products’ aesthetics, durability, and functionality. Whether you’re crafting metallic-textured paints, corrosion-resistant coatings, or cutting-edge composites, our premium-grade powder offers unmatched versatility and reliability.

✅ Precision Engineering: Our powder is treated to achieve uniform particle distribution, ensuring flawless dispersion in coatings and composites. ✅ Tailored Solutions: Adjust gloss, coverage, and color depth with customizable particle sizes (5-50µm) and dosages (1-10%). ✅ Industry-Proven Performance: Trusted by aerospace, automotive, and marine industries for UV resistance, thermal stability, and anti-corrosion properties. ✅ Safety First: Strict compliance with OSHA and ISO standards—safe handling guidelines included with every order.

🔥 Fast Turnarounds: Bulk orders shipped in 3-5 business days. 💡 Expert Support: Our technical team provides formulation guidance, troubleshooting, and SDS documentation. 🌍 Global Reach: Reliable delivery across the U.S., Europe, and Asia-Pacific.

📞 Contact Our Team Today! 👉 Request a Free Sample: Test our black aluminum powder in your formulations. Get Your Sample 👉 Download Technical Specs: Explore particle sizes, SDS, and application guides. View Resources 👉 Custom Quotes: Optimize costs with volume discounts. Get Pricing

Limited-Time Offer: Order 100+ kg and receive a complimentary dispersion optimization consultation!

5Star Materials – Where Innovation Meets Reliability. 🔗 Explore Products | 📧 sales@5starmaterials.com | 📞+86-18001668319

Nous vous suggérons de communiquer avec nous avant d'acheter, nous prendrons en compte tous les aspects et nous vous proposerons un plan de prix juste et raisonnable. En nous choisissant, vous obtiendrez le meilleur produit et le meilleur rapport qualité-prix.

Choosing the right size of product gives you the best value for money. Our Metal Flash Aluminum Silver Paste is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

Plus la quantité achetée est importante, plus le prix unitaire sera bas. Les commandes en gros nous permettent de mieux répartir nos coûts de production et d'exploitation, c'est pourquoi nous sommes heureux de proposer des prix réduits pour les achats en gros.

Le moment et le mode de paiement que vous choisissez ont également une incidence sur le prix. Par exemple, un paiement anticipé intégral peut donner lieu à un prix plus favorable, car il réduit le coût du capital. Veuillez discuter de l'option de paiement la plus appropriée avec notre équipe de vente.

Le transport et la logistique sont également des facteurs qui influencent le coût total de possession. Selon les modes de transport et les destinations, les frais d'expédition varient. Les droits de douane, l'assurance et d'autres coûts doivent également être pris en compte. En calculant ces facteurs avant l'achat, vous pouvez estimer le coût total avec plus de précision.

Chez Five Star Material, nous comprenons que chaque projet est unique et notre objectif est de fournir les meilleures solutions personnalisées à chaque client.

Nous vous contacterons dans les 24 heures.

Pour toute demande urgente, veuillez nous contacter par whatsapp : +86-18001668319