Choosing an aluminum pigment manufacturer can seem like a simple choice. But, the industry changes fast because of global competition and new technology. Companies notice new trends each year:

- Environmental sustainability pushes for greener ways to make products.

- Nano-aluminum pigment synthesis makes products shinier and stronger.

- Smart coatings and solvent-free manufacturing create better rules.

- More people want these products in cars, packaging, electronics, and buildings, especially in Asia-Pacific.

Checking your supplier often helps keep quality high, save money, and find new ideas in this fast-changing market.

Key Takeaways

- Pick aluminum pigment manufacturers who always give you good products. These products should meet tough industry rules.

- Find suppliers who use new ideas and care about the environment. This helps them keep up with new technology and laws.

- Check your supplier often. Look at their quality, delivery, prices, and customer help. This can help you avoid problems.

- Good supply chains and helpful customer service are important. They make sure you get your products on time. They also help your projects go well.

- Be careful when you change suppliers. This helps keep your product quality high. It also stops delays in making things.

Key Criteria for Aluminum Pigment Manufacturer Selection

Product Quality

Product quality is very important for any aluminum pigment manufacturer. Good pigments give the same color, shine, and last a long time in coatings. Manufacturers use strict rules to make sure their pigments are good enough for the industry. The table below shows common quality standards:

| Quality Aspect | Standard / Method | Description / Purpose |

|---|---|---|

| Particle Size Distribution | ISO 13320-1 | Checks particle size with a laser. |

| Screen Analysis | DIN 53196, ASTM 11 | Uses sieves to check particle size and how it spreads out. |

| Volatile Content | DIN 55923 | Tests for things that can evaporate or stay in pigments. |

| Colorimetric Evaluation | CIELab*, LCh° systems | Measures color, shine, and how bright or strong the color is. |

| Gassing Stability | Non-standardized test | Checks if hydrogen forms in water-based coatings for pigment safety. |

| Stabilization Methods | Corrosion inhibitors, encapsulation | Makes pigments more stable in coatings. |

Top manufacturers check raw materials with alloy and chemical tests. They look at aluminum billets for problems and watch temperature and pressure during extrusion. These steps help make sure pigments are safe and high quality. Many companies also use green ways to make pigments, recycle aluminum, and do research to make pigments last longer.

Consistency

Consistency means every batch of pigment works the same way. Good aluminum pigment manufacturers control their machines and check each batch. They use different ways to check consistency:

- Color standards like RAL help match colors.

- Coating thickness keeps the look even.

- Metallic pigment content and flake size control the effect.

- Flake position and spread make finishes smooth.

- Particle size and oxygen levels check batch quality.

- Trials on real equipment set limits for batches.

- Bonded metallic pigments help flakes spread evenly.

Manufacturers keep things consistent by watching machine settings and how much they recycle. This makes sure customers always get the same good product.

Innovation

Innovation helps the industry grow. The best aluminum pigment manufacturers spend money on research to make better pigments. New ideas include:

- Very small pigments that are extra shiny and cover well.

- Water-based and low-VOC coatings that are better for the environment.

- Better pigment shape and size for even results.

- Special colored and functional aluminum pigments.

- Spherical aluminum powder for better control of materials.

- New uses like solar aluminum paste.

- Digital tools to make new products faster and help customers.

Innovation lets manufacturers meet new needs, follow rules, and give great metallic finishes for cars, electronics, and buildings.

Tip: Companies that focus on new ideas often do better in being green and making high-performing products, which helps customers win.

Compliance

Following rules is very important for any aluminum pigment manufacturer. In the US and EU, companies must meet tough safety and environmental rules. Main compliance areas are:

- Lowering VOCs with water-based or thick coatings.

- Handling dry aluminum flakes safely to stop explosions.

- Controlling hydrogen gas in water-based coatings.

- Keeping coatings working well, like how they flow and stick.

- Using surface treatments to make coatings stronger and look better.

- New packaging to make handling safer.

New rules often say pigments must not have dangerous stuff and must be easy to recycle. Manufacturers need to know about new laws, like EPA checks and PFAS rules, to keep following the law.

Customer Support

Good customer support makes top manufacturers stand out. Industrial buyers need more than just good products—they want help during the whole project. Common support services are:

| Customer Support Aspect | Description |

|---|---|

| Expert Technical Support | Help and advice to make customer work better. |

| Tailor-made Solutions | Custom products and services for special needs. |

| Packaging Options | Different package sizes for all kinds of production. |

| Timely Shipment | Global supply chain for fast delivery. |

| Quality Assurance | Certifications like ISO 9001 and ISO 14001; full control from start to finish. |

| Environmental Safety Compliance | Help with safety and health, plus up-to-date certificates. |

| Technical Services & Lab Analysis | Testing, troubleshooting, and pilot lines to copy customer conditions. |

| Industry Engagement | Joining industry groups for standards and expert knowledge. |

Quick technical help, clear talks, and strong after-sales service help customers fix problems fast and keep projects moving.

Pricing

Pricing depends on how much it costs to make and what the market is like. Changes in aluminum prices change costs for every aluminum pigment manufacturer. When aluminum costs more, making pigments costs more, so prices may go up to keep profits. If companies cannot raise prices, they make less money. Raising prices can lose customers, but lowering prices can help get more buyers.

Manufacturers use different ways to handle price changes:

- Long-term buying deals.

- Getting supplies from many places.

- New technology to lower costs.

- Looking for other materials.

- AI pricing models to keep profits steady.

Costs are also different in each region, and things like inflation matter too. Companies that control costs well can offer better prices and keep a steady supply.

Supply Chain

A strong supply chain means products arrive on time and are always good quality. Important parts of a good supply chain are:

- Strict quality checks and certifications.

- Custom products for special uses.

- Same quality and delivery every time.

- Technical help and expert advice.

- Good for the environment and fair practices.

- Good prices and quality together.

- Steady raw material supply and fast shipping.

- Supplier reputation and strong finances.

Good shipping and delivery stop delays. Manufacturers with strong supply chains can handle problems and keep customers happy.

Top Aluminum Pigment Manufacturers

Global Leaders

Some companies are known around the world for making aluminum pigments. These companies use new technology and have many products. They also have strong supply chains that customers can trust.

- ALTANA is big in Europe and North America. In 2023, they made more space to make 20,000 metric tons. This shows they want to grow and try new things.

- Silberline Manufacturing Co. Inc. has many products and strong factories in North America. Their business helps many different industries.

- BASF SE sells many kinds of aluminum pigments. They are known for new ideas and have customers all over the world.

- Arasan Aluminium Industries can now make 15,000 metric tons. This makes them stronger in the market.

These top companies spend money on research, keep quality high, and change fast when the market changes.

| Country | Aluminum Pigment Manufacturers |

|---|---|

| Germany | Carl Schlenk AG, ECKART GmbH, BASF SE |

| USA | Silberline Manufacturing Co., Inc., Sun Chemical Corporation |

| Japan | Asahi Kasei Corporation |

| China | Changsha Sinotack Chemicals Co., Ltd. |

| India | Arasan Aluminium Industries Ltd. |

Regional Players

Regional companies are important for local markets. They often make special products and give flexible service.

- ILMET S.p.A. in Italy helps European customers with special products.

- Alba Aluminiu gives good supply and help in Eastern Europe.

- Hefei Sunrise Aluminum Pigments Co. Ltd and Changsha Sinotack Chemicals Co., Ltd. in China meet the needs in Asia-Pacific.

- Geotech International BV in the Netherlands and The Arasan Aluminum Industries Ltd. in India have strong local delivery and customer help.

These companies help customers follow local rules and keep up with market changes.

Product Specialization

New ideas in eco-friendly and high-quality metallic pigments are changing the industry. Many companies now focus on products that are good for the environment and work really well.

- BASF SE, Altana AG, and Carl Schlenk AG make water-based, halogen-free, and safe pigments. Their products follow tough environmental rules.

- Silver Rocket makes aluminum paste for cars and factories. Their products are shiny, last long, and are better for the environment.

- Some special metallic pigments now use nano-technology for cool effects like holograms and color changes. These are used in cars and electronics.

Companies that use new technology and care about the environment are top picks for customers who want the best from an aluminum pigment manufacturer.

Evaluating Your Aluminum Pigment Manufacturer

Performance Checklist

A careful review helps companies see if their supplier is good enough. The table below shows what to check when looking at an aluminum pigment manufacturer:

| Criteria Category | Key Checklist Items |

|---|---|

| Performance Tests | Do first and regular tests with EPA Method 5. Check if control devices work right. Test again every five years. New sources must pass tests in 180 days after starting. |

| Continuous Monitoring | Use alarms for bag leaks. Watch important numbers all the time with CPMS. |

| Control Technology | Put controls on vessels with metal HAP solids if they hold 250 gallons or more. Set limits for new and old sources. |

| Timing Requirements | First test must be done by February 22, 2024. Companies have one year to add new controls. Sometimes, they can get up to two years. |

| Compliance Steps | Check if dry solids with metal HAP are used. Make sure control technology works or has permits. Do EPA-approved tests before the deadline. Add devices to control dust if needed. |

| Documentation | Write down reviews of technology and show proof of following rules for checks. |

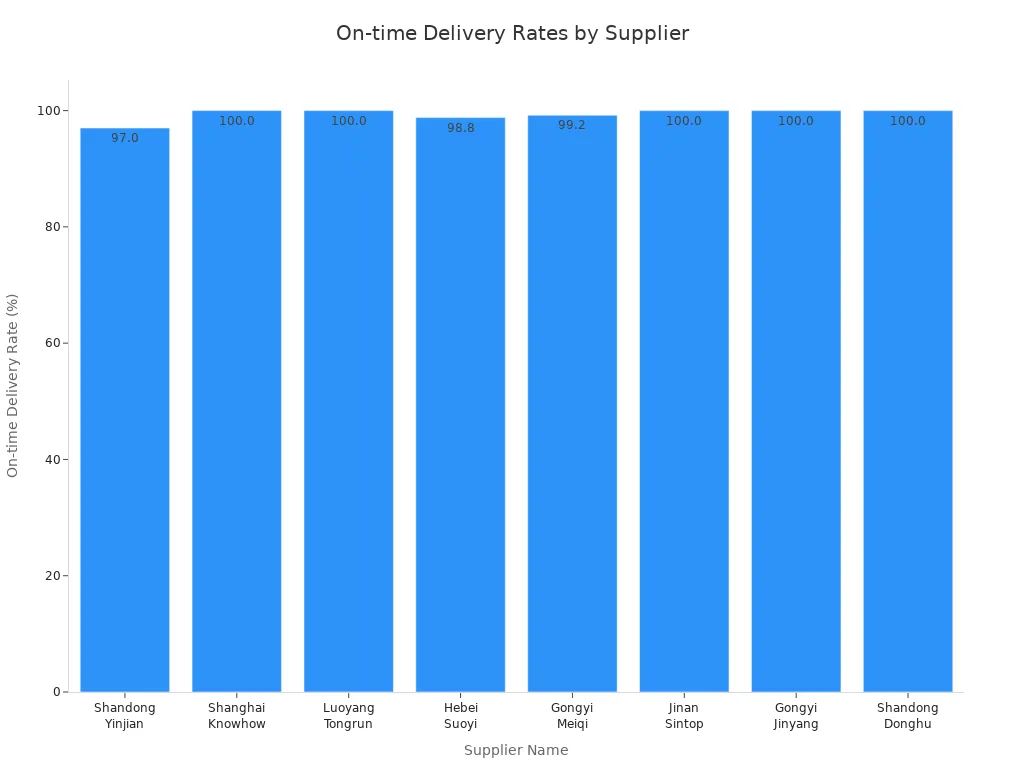

Companies should also look at how well the supplier delivers and helps customers. The best suppliers deliver on time more than 97% of the time. The chart below shows how fast top suppliers deliver:

Good suppliers answer questions fast, usually in three hours. They also get lots of repeat orders. Service is very important, especially when supply chains have problems.

Red Flags

Some warning signs show a supplier may not be good. Companies should look out for:

- Deliveries that are late or missed often

- Pigment quality changes from batch to batch

- Slow answers or bad communication

- No current certificates or missing rule papers

- Prices go up for no reason or have hidden costs

- Not much technical help or no custom products

🚩 If these problems happen a lot, the supplier may not help your business grow or keep up quality.

When to Switch

Sometimes, companies need to change suppliers if problems do not stop. Think about switching if:

- Quality problems hurt your products or upset customers

- Late deliveries mess up plans or cost more money

- Not following rules could mean fines or legal trouble

- Customer service does not fix things fast

- You need new ideas, but your supplier cannot help

Checking your supplier often makes sure your aluminum pigment manufacturer still fits your needs and follows industry rules.

Changing Aluminum Pigment Manufacturer

Comparing Suppliers

Companies need a simple plan to compare suppliers. This helps them pick the right one.

1. Check quality by looking at chemical makeup, purity, and particle size. Make sure the supplier has the right certificates.

2. Look at how well the pigment covers, lasts, sticks, and its color and shine.

3. Compare prices and costs, including shipping and how well the pigment works.

4. See if the supplier is trusted, delivers on time, and helps after sales.

5. Match the pigment type to what you need it for.

6. Study the market to compare features, prices, and service.

7. Pick suppliers with good reputations, the right certificates, and green practices.

Tip: Using a checklist helps companies avoid mistakes and get better products.

Transition Planning

A smooth switch stops delays in making products. Companies should talk often with both old and new suppliers. They need to keep enough stock during the change. Backup plans and extra suppliers help stop supply problems. Working with more than one supplier lowers risk. Checking how the new supplier does keeps quality and delivery good. Companies should use tools to watch shipments and stock. Planning ahead and guessing what they will need helps stop problems.

Quality Assurance

Keeping quality high during a supplier change needs teamwork. Leaders must help and support the quality system. Workers should join checks and get training to find problems early. Companies need to look at and fix their quality system often. Setting clear goals and using data helps make things better. Talking with customers helps fix issues fast. Asking customers for feedback and using surveys keeps service strong. Using a plan-do-check-act cycle makes sure quality stays good in every step.

Note: Changes in pigment can change how things look and work. Companies should test new pigments to make sure they are safe and work well, especially where rules matter.

Checking your supplier often helps your company keep up. Rules, technology, and what people want can change fast. This can make a different supplier better for you. Companies use tools to watch how suppliers do their job. They look at supply chain analysis, price trends, and market share grids. These tools help track how well suppliers perform. Making supplier checks a regular habit helps you make smart choices. It also helps your company do well for a long time.

FAQ

What makes a good aluminum pigment manufacturer?

A good manufacturer gives you pigments that always work well. They follow strict rules set by the industry. They use new technology to make better products. Good customer support and on-time delivery make them stand out.

How often should companies review their pigment suppliers?

Experts say you should check your suppliers every 12 to 18 months. Regular reviews help you stay ahead and spot problems early.

Why do pigment prices change so often?

Pigment prices go up and down for many reasons. The cost of raw aluminum and energy can change. Market demand also affects prices. Big world events and supply chain problems can make prices move too.

Can switching suppliers affect product quality?

- Yes, changing suppliers can make your product look or work differently.

- Companies need to test new pigments before using them everywhere.

- Quality checks help stop any surprises.

What certifications should a top supplier have?

| Certification | Purpose |

|---|---|

| ISO 9001 | Quality management |

| ISO 14001 | Environmental safety |

| REACH | Chemical compliance |

These certificates show the supplier follows important global rules.