The role of aluminium paste in lightweight concrete is mainly as a foaming agent and its performance directly affects the quality and properties of the concrete.

The role of aluminium paste in lightweight concrete is mainly as a foaming agent and its performance directly affects the quality and properties of the concrete. The following are a few key parameters that affect the performance of aluminium paste:

1. Purity: The purity of an aluminium paste is usually expressed as a percentage. Higher purity usually means that there are more active ingredients in the paste and the foaming effect may be better. For example, 65% purity of aluminium paste means that it may contain other ingredients in addition to aluminium.

2, Active aluminium content: active aluminium content refers to the percentage of aluminium in the paste that can participate in the chemical reaction and produce gas. Higher reactive aluminium content usually means that more gas can be produced during the reaction process, thus forming more foam.

3, Particle size: particle size (D50) means that under certain conditions, 50% of the particles are smaller than this size in diameter. Aluminium paste with smaller particle size can release gas faster and more evenly when reacting with water, which helps to form a uniform foam structure.

4, Non-volatile content: non-volatile content refers to the proportion of non-volatile components in the aluminium paste after heating under specific conditions. This parameter reflects the stability of the aluminium paste in the heating process, the higher the non-volatile content, indicating that the aluminium paste in the heating process, the less the loss of components.

These parameters determine the performance of aluminium paste in lightweight concrete, including its foaming ability, stability and the physical properties of the final concrete.

1. Chemical analysis method: Separate the aluminium element from the sample by dissolving the concrete sample, and then use chemical reagents for quantitative determination. This method has high accuracy, but requires professional laboratory conditions and operating skills.

2、Spectral analysis methods: including atomic absorption spectrometry (AAS), inductively coupled plasma emission spectrometry (ICP-OES) and X-ray fluorescence spectrometry (XRF). These methods can directly measure the content of aluminium element in the sample, with fast and accurate characteristics, but need expensive instrumentation and professional technicians to operate.

*Atomic Absorption Spectrometry (AAS): quantitative analysis using the absorption of aluminium atoms at specific wavelengths of light.

*Inductively Coupled Plasma Emission Spectrometry (ICPES): quantitative analysis by exciting aluminium atoms in the sample and measuring the characteristic spectra emitted by them.

* X-ray fluorescence spectrometry: using X-ray irradiation of the sample, by measuring the fluorescence intensity emitted by the aluminium atoms after being excited to determine the aluminium content.

3. Sieving method: For lightweight concrete containing a high amount of aluminium powder, the aluminium powder particles can be separated from the concrete by sieving and weighed to calculate the aluminium powder content. This method is simple and fast, but the accuracy is relatively low, only for specific cases.

4, Microscope observation method: the use of microscope observation of concrete samples in the form of aluminium powder particles and distribution, combined with image processing technology for quantitative analysis. This method is applicable to the need to understand the distribution of aluminium powder in concrete.

5、Professional testing organisations: If you do not have the conditions to measure by yourself, you can send the samples to professional testing organisations for testing. These institutions usually have advanced equipment and professional technicians, and can provide accurate and reliable test results.

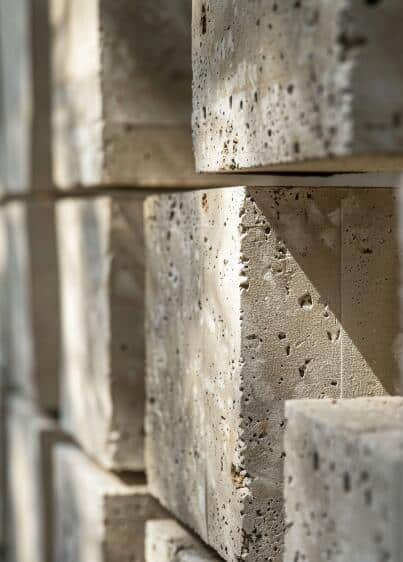

1.Density and weight: the increase of aluminium powder content, the amount of hydrogen produced by the aluminium paste in the concrete increases, leading to an increase in the number of bubbles inside the concrete, thus reducing the density and weight of the concrete.

2.Strength: the right amount of aluminium powder can improve the compressive strength of concrete, because the aluminium powder particles can fill the tiny pores in the concrete, reduce the porosity and improve the compactness. However, when the content of aluminium powder is too high, too many bubbles may lead to loose internal structure of concrete, but reduce the strength.

3, durability: aluminium powder and other components in the concrete reaction, can form new cementitious materials, help to improve the durability of concrete. However, too much aluminium powder may produce unfavourable chemical reactions, affecting durability.

4, Thermal insulation: the increase of bubble structure improves the thermal insulation of concrete, the higher the content of aluminium powder, the better the thermal insulation effect may be.

5.Constructability: the right amount of aluminium powder can improve the fluidity and workability of concrete, and improve the construction efficiency. However, too much aluminium powder may cause the concrete to be too loose, which is not conducive to construction.

アルミペーストの使用量は、AACの体積密度によって異なります。同じ品質のアルミペーストを使用する場合、製品の体積密度が高いほどアルミペーストの使用量は少なくなります。

実際、製品の体積密度からアルミペーストの使用量を正確に計算することができます:

アルカリ性環境において、アルミニウムペーストが水中で水素を置換する反応式に基づく:

2AL 3Ca(OH)2 6H2O-3Ca.AI2O3.6H2O 3H2↑.

統計によると、2グラムの純金属アルミニウムは3グラムのH2を生成することができますが、標準的な条件下では、1グラムの気体の体積は22.41であり、アルミニウムの原子量は27です。したがって、アルミニウムペーストのガス発生量は

Vo=22.4X1.241/[3/2X27]g

上記の式によれば、様々な条件下でのアルミニウムペーストのガス発生量は、蒸気状態の式(V1/T1)=(V2/T2)を用いて計算することができる:

AACの体積は、2つの部分に簡略化することができます:1つは基材の承認された体積であり、もう1つはアルミニウムペーストがガス化された後に形成される細孔の体積です。細孔容積によって、アルミニウムペーストの量を計算することができます:

Mアルミニウム=V孔/(V2K)

種類ではMアルミニウム-自社製品に使用されているアルミニウムペーストの量(g/立方);

K--活性アルミニウム含有量

細孔容積は製品容積に等しく、原料の量とそれぞれの割合を組み合わせて原料や水の容積を減らす)。しかし、製造過程において、ガス発生量は温度変化やスラリーの粘度など多くの要因に影響される。理論上の計算では、アルミペーストの量は不可能であり、不要である。工場は社会的経験に基づいて選択し、随時調整する。一般的にアルミペーストを使用する場合、600kg/立方気泡コンクリートを製造するために、アルミペーストを8/10,000乾燥材料の割合で添加する。

| 製品名 | 固形分(%) | 活性アルミナ(%) | かさ密度 | 粒子径の中央値 (D₅₀) | AACに最適 |

|---|---|---|---|---|---|

| DEG-60 | 70% | ≥96 | 0.15 | 58-62 | <600 |

| DEG-40 | 70% | ≥94 | 0.15 | 36-42 | <500 |

| DEG-35 | 70% | ≥94 | 0.15 | 33-35 | <400 |

| DEG-25 | 70% | ≥94 | 0.15 | 25-27 | <400 |

| DEG-18 | 70% | ≥92 | 0.11 | 17-19 | <350 |

購入する前に、私たちと十分なコミュニケーションを取ることをお勧めします、私たちは確かにすべての側面を考慮し、公正かつ合理的な価格プランを提供します。私たちを選択することで、あなたのお金のための最高の製品と最高の価値を得るでしょう。

Choosing the right size of product gives you the best value for money. Our Aluminum Paste for Lightweight Concrete Brick is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

購入数量が多ければ多いほど、単価は安くなります。大量注文により、生産コストと運営コストをよりよく分担することができますので、大量購入の割引価格を喜んで提供させていただきます。

お支払いのタイミングや方法も価格に影響します。例えば、全額前払いの場合、資本コストを削減できるため、より有利な価格となる可能性があります。最適なお支払い方法については、営業チームまでご相談ください。

輸送とロジスティクスも、総所有コストに影響する要素である。輸送手段や目的地が異なれば、輸送コストも異なる。関税、保険、その他の費用も考慮する必要があります。購入前にこれらの要素を事前に計算することで、総コストをより正確に見積もることができます。

気泡入りアルミニウムペースト(スラリー)/パウダーの製造工程は、最終製品の品質と性能を決定する上で極めて重要である。本章では、気泡入りアルミニウムペースト(スラリー)/パウダーの製造工程における各段階の製造フロー、主要技術、管理ポイントについて詳述し、この重要な材料の製造について読者の理解を深める一助とする。

気泡入りアルミニウム・ペースト(スラリー)/パウダーの製造フローには、通常、以下の主なステップが含まれる:

生産を開始する前に、原材料の選択と準備が重要である。その メイン 原料には、アルミニウム粉末、添加剤(DEG、分散剤など)、その他の成分が含まれる。アルミニウム粉末の選択は、通常、粒径、活性、純度に基づいて行われる。活性の高いアルミニウム粉末は、水と反応した際に水素ガスを多く発生させることができるため、より優れたガス発生効果を得ることができる。添加剤の選択は、流動性の改善や反応性の向上など、気泡入りアルミニウムペーストにおける役割を考慮する必要がある。

The prepared aluminum powder and additives are mixed in a certain proportion. This step usually uses high-efficiency mixing equipment to ensure uniform component distribution and avoid agglomeration. The mixing time and speed must be strictly controlled during the mixing process to ensure a sufficient combination of aluminum powder and additives, laying a good foundation for subsequent reactions.

The mixed materials need to be ground to reach the specified particle size. This step is crucial for improving the activity of the aluminum powder. Using ball mills or other types of grinding equipment can effectively reduce the particle size and increase the surface area of the aluminum powder, thereby enhancing its reactivity with water. After grinding, the materials must also be classified to ensure particle size and product distribution consistency.

In this step, the ground aluminum powder is mixed with water and other necessary additives to form the aluminum paste. The reaction conditions at this time (such as temperature and stirring speed) need to be controlled to ensure that the reaction between aluminum powder and water is sufficient to generate a stable bubble structure. Better gas generation effect and fluidity can be obtained through reasonable proportioning and stirring.

The prepared aerated aluminum paste (slurry) must pay attention to environmental conditions during storage and transportation, avoiding high temperatures and humidity to prevent premature reaction and failure. Its physical and chemical properties should be checked regularly during storage to ensure stable product quality. Finally, the aluminum paste must be packaged according to standards to ensure no leakage or deterioration occurs during transportation.

In the production process of aerated aluminum paste (slurry)/powder, several key technologies have a profound impact on the performance and quality of the final product:

Ball milling is an important technology for grinding aluminum powder. The physical grinding process can effectively reduce the particle size of the aluminum powder and increase its specific surface area. Smaller particle sizes help enhance the reactivity of the aluminum powder, allowing it to generate hydrogen gas more rapidly when reacting with water, thereby forming a uniform and stable bubble structure.

Classification technology plays an important role in ensuring the consistency of the particle size distribution of aluminum powder. Through classification, aluminum powders of different particle sizes can be separated, improving the activity and adaptability of the material. A suitable particle size distribution can optimize bubble formation and enhance aerated concrete’s strength and thermal insulation performance.

In the preparation process of aluminum paste, controlling reaction conditions (such as temperature and time) is crucial. Reasonable reaction conditions can ensure that the reaction between aluminum powder and water is sufficient to generate an adequate number of evenly distributed bubbles. The application of reaction control technology helps to improve the stability and consistency of the product.

Product performance can be improved by continuously optimizing the formulation of aluminum paste (slurry). For example, adding appropriate amounts of certain additives can increase the aluminum powder’s reaction rate and improve the aluminum paste’s fluidity and stability. In addition, for different application needs, enterprises can develop various types of aluminum paste to meet the market’s diverse needs.

In production, controlling environmental conditions (such as temperature and humidity) is also crucial to ensure product quality. Especially in the storage and transportation stages, it is necessary to provide suitable environmental conditions to prevent the aluminum paste from failing or deteriorating due to environmental changes.

Quality control is an important link throughout the production process to ensure the stable performance of aerated aluminum paste (slurry)/powder. Enterprises usually establish a complete quality management system, including:

Before production begins, all raw materials must undergo strict quality inspection to ensure they meet production standards. The aluminum powder’s activity, purity, and particle size distribution need to be tested to determine whether it meets the production requirements.

During the production process, the parameters of each stage (such as temperature, humidity, mixing time, etc.) are monitored in real-time to ensure that the production process is always in the best state. In addition, online testing equipment can detect and adjust problems in time to prevent the generation of unqualified products.

After the product is produced, comprehensive performance testing of the finished product is required, including indicators such as fluidity, gas generation, and compressive strength, to ensure that it meets relevant standards and customer needs. Only products that have passed strict testing can be put on the market for sale.

Questions Customers Often Ask When Looking for Aluminum Paste for Lightweight Concrete Brick Factory

1.あなたの工場は Aluminum Paste for Lightweight Concrete Brick manufacturer?

回答はい、当社は長年の生産経験と高度な生産技術を持つDEGアルミニウムペーストの専門メーカーです。

2. What are the quality indexes of Aluminum Paste for Lightweight Concrete Brick in your factory?

Answer:The quality indexes of Aluminum Paste for Lightweight Concrete Brick in our factory are as follows:

固体含有:70±1

ディレイ・エアレーション時間:1~3分

活性アルミニウム: ≥92

粒子径の均一性:高い

3. What is the price of Aluminum Paste for Lightweight Concrete Brick in your factory?

A: The price of Aluminum Paste for Lightweight Concrete Brick in our factory depends on the specific model and quantity, please contact us for detailed quotation.

4.貴社の工場でのDEGアルミニウムペーストの最小発注量はどのくらいですか?

A: 私達の工場からの DEG アルミニウム スラリーの最低順序量は 1 トン、決まりますですです。

5. What kind of after-sale service can your Aluminum Paste for Lightweight Concrete Brick provide?

回答:弊社工場では以下のアフターサービスを行っております:

製品の品質保証

技術指導

アフターサービス・トラッキング

6. Can your Aluminum Paste for Lightweight Concrete Brick be customized?

回答はい、DEGアルミニウムペーストの生産は、お客様のご要望に応じてカスタマイズすることができます。

ファイブスターマテリアルでは、すべてのプロジェクトがユニークであることを理解し、私たちの目標は、各顧客のために最高のカスタマイズされたソリューションを提供することです。