Aluminium Paste & Powder (APP) is a key aerating agent for producing lightweight aerated concrete. It reacts with alkaline substances to release hydrogen, creating a porous structure that enhances thermal insulation, soundproofing, and construction flexibility. Ideal for reducing building weight and improving earthquake resistance.

アルミニウムペースト&パウダー(APP)は、AACブロックの製造において重要な気泡剤である。アルカリ性物質と反応して水素ガスを放出し、軽量で多孔質の構造を形成します。以下はその主な特徴である:

アルカリ性環境(例えば、Ca(OH)₂)では、アルミニウムペースト&パウダーは水と反応して水素ガスを発生する:

2アル+3Ca(OH)2+6H2O→3酸化カルシウム⋅アル2O3⋅6H2O+3H2↑

この反応により、スラリー内に均一に分布した気孔が形成され、最終製品の密度は500~700kg/m³と、従来のコンクリートの5分の1にまで低下する。

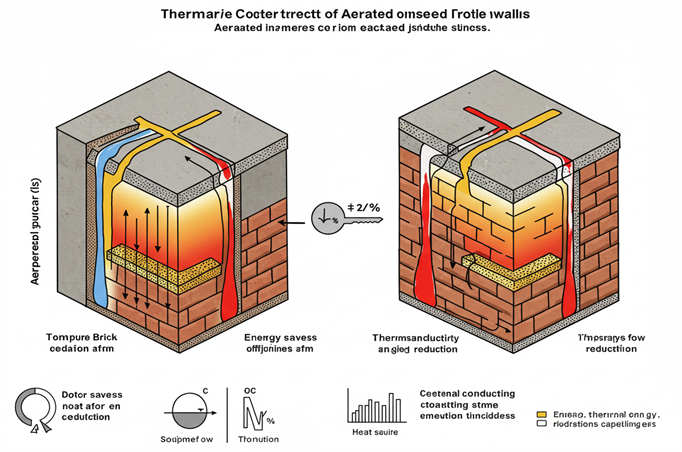

気孔の大きさと分布は、AACの断熱性と防音性を直接決定する。 理想的な細孔構造を実現するためにアルミニウム粒子は、適切な細かさ(0.075mmふるい上で3%以下の残渣)と高い活性アルミニウム含有量(85%以上)でなければならない。

気泡入りアルミニウムペースト(スラリー)/パウダーの製造工程は、最終製品の品質と性能を決定する上で極めて重要である。本章では、気泡入りアルミニウムペースト(スラリー)/パウダーの製造工程における各段階の製造フロー、主要技術、管理ポイントについて詳述し、この重要な材料の製造について読者の理解を深める一助とする。

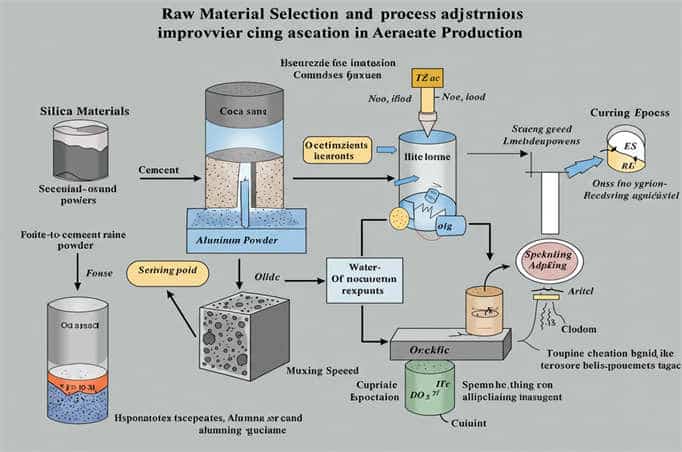

気泡入りアルミニウム・ペースト(スラリー)/パウダーの製造フローには、通常、以下の主なステップが含まれる:

生産を開始する前に、原材料の選択と準備が重要である。その メイン 原料には、アルミニウム粉末、添加剤(DEG、分散剤など)、その他の成分が含まれる。アルミニウム粉末の選択は、通常、粒径、活性、純度に基づいて行われる。活性の高いアルミニウム粉末は、水と反応した際に水素ガスを多く発生させることができるため、より優れたガス発生効果を得ることができる。添加剤の選択は、流動性の改善や反応性の向上など、気泡入りアルミニウムペーストにおける役割を考慮する必要がある。

The prepared aluminum powder and additives are mixed in a certain proportion. This step usually uses high-efficiency mixing equipment to ensure uniform component distribution and avoid agglomeration. The mixing time and speed must be strictly controlled during the mixing process to ensure a sufficient combination of aluminum powder and additives, laying a good foundation for subsequent reactions.

The mixed materials need to be ground to reach the specified particle size. This step is crucial for improving the activity of the aluminum powder. Using ball mills or other types of grinding equipment can effectively reduce the particle size and increase the surface area of the aluminum powder, thereby enhancing its reactivity with water. After grinding, the materials must also be classified to ensure particle size and product distribution consistency.

In this step, the ground aluminum powder is mixed with water and other necessary additives to form the aluminum paste. The reaction conditions at this time (such as temperature and stirring speed) need to be controlled to ensure that the reaction between aluminum powder and water is sufficient to generate a stable bubble structure. Better gas generation effect and fluidity can be obtained through reasonable proportioning and stirring.

The prepared aerated aluminum paste (slurry) must pay attention to environmental conditions during storage and transportation, avoiding high temperatures and humidity to prevent premature reaction and failure. Its physical and chemical properties should be checked regularly during storage to ensure stable product quality. Finally, the aluminum paste must be packaged according to standards to ensure no leakage or deterioration occurs during transportation.

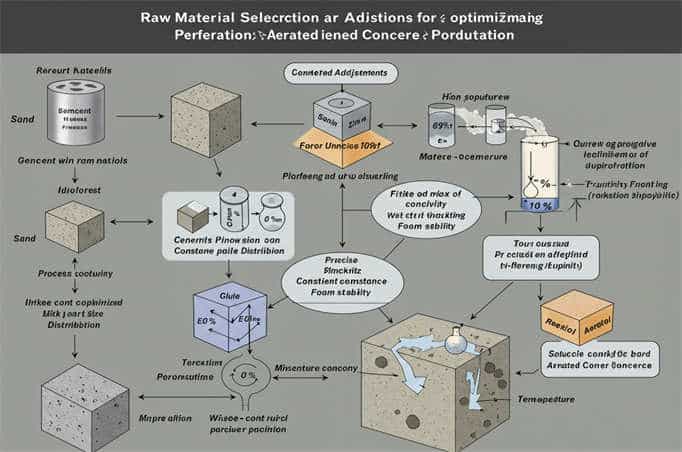

In the production process of aerated aluminum paste (slurry)/powder, several key technologies have a profound impact on the performance and quality of the final product:

Ball milling is an important technology for grinding aluminum powder. The physical grinding process can effectively reduce the particle size of the aluminum powder and increase its specific surface area. Smaller particle sizes help enhance the reactivity of the aluminum powder, allowing it to generate hydrogen gas more rapidly when reacting with water, thereby forming a uniform and stable bubble structure.

Classification technology plays an important role in ensuring the consistency of the particle size distribution of aluminum powder. Through classification, aluminum powders of different particle sizes can be separated, improving the activity and adaptability of the material. A suitable particle size distribution can optimize bubble formation and enhance aerated concrete’s strength and thermal insulation performance.

In the preparation process of aluminum paste, controlling reaction conditions (such as temperature and time) is crucial. Reasonable reaction conditions can ensure that the reaction between aluminum powder and water is sufficient to generate an adequate number of evenly distributed bubbles. The application of reaction control technology helps to improve the stability and consistency of the product.

Product performance can be improved by continuously optimizing the formulation of aluminum paste (slurry). For example, adding appropriate amounts of certain additives can increase the aluminum powder’s reaction rate and improve the aluminum paste’s fluidity and stability. In addition, for different application needs, enterprises can develop various types of aluminum paste to meet the market’s diverse needs.

In production, controlling environmental conditions (such as temperature and humidity) is also crucial to ensure product quality. Especially in the storage and transportation stages, it is necessary to provide suitable environmental conditions to prevent the aluminum paste from failing or deteriorating due to environmental changes.

Quality control is an important link throughout the production process to ensure the stable performance of aerated aluminum paste (slurry)/powder. Enterprises usually establish a complete quality management system, including:

Before production begins, all raw materials must undergo strict quality inspection to ensure they meet production standards. The aluminum powder’s activity, purity, and particle size distribution need to be tested to determine whether it meets the production requirements.

During the production process, the parameters of each stage (such as temperature, humidity, mixing time, etc.) are monitored in real-time to ensure that the production process is always in the best state. In addition, online testing equipment can detect and adjust problems in time to prevent the generation of unqualified products.

After the product is produced, comprehensive performance testing of the finished product is required, including indicators such as fluidity, gas generation, and compressive strength, to ensure that it meets relevant standards and customer needs. Only products that have passed strict testing can be put on the market for sale.

| 特徴 | アルミペースト(水性) | 乾燥アルミニウムパウダー |

|---|---|---|

| 生産プロセス | 脱脂不要の湿式研削 | 乾式研磨、脱脂が必要 |

| 安全性 | 粉塵爆発の危険性なし | 可燃性、爆発性、窒素保護が必要 |

| 使いやすさ | スラリーに直接添加、良好な分散性 | 脱脂前処理が必要 |

| 環境への影響 | 低汚染、容易な廃水処理 | エネルギー消費量が多く、公害が多い |

Below are key testing methods and technical requirements based on industry standards and practical applications:

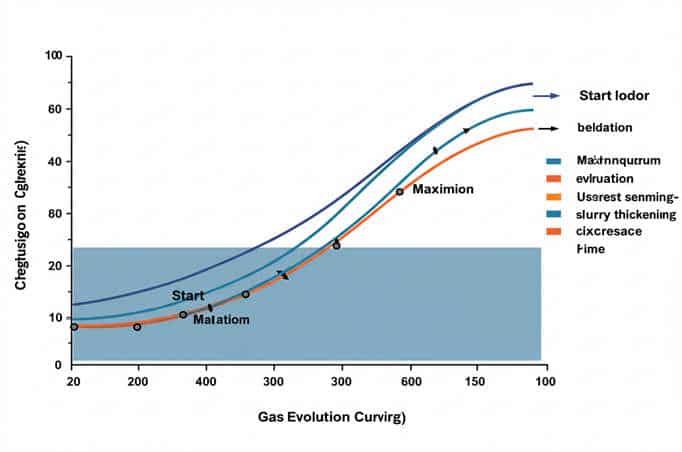

Aluminium Paste & Powder must aerate at a rate that aligns with slurry thickening:

Maintain slurry temperature at 40-60°C. Excessive heat accelerates aeration, risking uncontrolled expansion, while low temperatures slow aeration, leading to uneven pore distribution.

Fiver Star New Materials ensures optimal concrete quality, enhancing thermal efficiency, mechanical strength, and construction adaptability by fine-tuning aeration parameters.

| 製品名 | 固形分(%) | 活性アルミナ(%) | かさ密度 | 粒子径の中央値 (D₅₀) | AACに最適 |

|---|---|---|---|---|---|

| DEG-60 | 70% | ≥96 | 0.15 | 58-62 | <600 |

| DEG-40 | 70% | ≥94 | 0.15 | 36-42 | <500 |

| DEG-35 | 70% | ≥94 | 0.15 | 33-35 | <400 |

| DEG-25 | 70% | ≥94 | 0.15 | 25-27 | <400 |

| DEG-18 | 70% | ≥92 | 0.11 | 17-19 | <350 |

購入する前に、私たちと十分なコミュニケーションを取ることをお勧めします、私たちは確かにすべての側面を考慮し、公正かつ合理的な価格プランを提供します。私たちを選択することで、あなたのお金のための最高の製品と最高の価値を得るでしょう。

適切なサイズの製品を選択することで、最高のコストパフォーマンスが得られます。弊社のメタルフラッシュアルミニウムシルバーペーストは、幅広い粒子サイズと純度を取り揃えており、価格は仕様によって異なります。お客様のニーズを詳細に伝え、適切なサイズを選択することで、最高のコストパフォーマンスを得ることができます。

購入数量が多ければ多いほど、単価は安くなります。大量注文により、生産コストと運営コストをよりよく分担することができますので、大量購入の割引価格を喜んで提供させていただきます。

お支払いのタイミングや方法も価格に影響します。例えば、全額前払いの場合、資本コストを削減できるため、より有利な価格となる可能性があります。最適なお支払い方法については、営業チームまでご相談ください。

輸送とロジスティクスも、総所有コストに影響する要素である。輸送手段や目的地が異なれば、輸送コストも異なる。関税、保険、その他の費用も考慮する必要があります。購入前にこれらの要素を事前に計算することで、総コストをより正確に見積もることができます。

At Five Star Materials, our Aluminium Paste & Powder for AAC produced in a delicate and rigorous process. Below is our basic production process:

私たちは信頼できるサプライヤーから高純度の原料を購入し、製品の品質を供給元から保証しています。

原料は粉砕され、アルミニウム・ブロックが後続の加工用の微粒子に変換される。

粉砕されたアルミニウムパウダーは、特別に配合された溶剤および添加剤と混合され、高速混合工程を経てブレンドされます。この工程は、アルミペーストの安定性と粒子の形状を決定するため、非常に重要です。

粉砕後、アルミニウムペーストはろ過システムに通され、不純物が取り除かれます。その後、当社の品質管理チームが、粒度、光沢、金属感など、製品に関する一連のテストを実施し、製品が当社の高い品質基準を満たしていることを確認します。

厳しい検査に合格した製品は、慎重に梱包された後、倉庫に保管され、お客様への出荷準備が整う。

これは基本的な生産工程であり、正確な工程は製品の特定の要件によって異なる場合があることに注意してください。ファイブスターマテリアルでは、品質管理を非常に重要視しており、生産工程の各段階で製品が厳しい品質基準を満たしていることを確認しています。

ファイブスターマテリアルでは、すべてのプロジェクトがユニークであることを理解し、私たちの目標は、各顧客のために最高のカスタマイズされたソリューションを提供することです。