Black Masterbatch is a highly concentrated pigment dispersion composed of carbon black, carrier resin (e.g., PP, PE, ABS), and additives. It delivers vibrant, consistent coloration for plastic products via injection molding, blow molding, extrusion, or fiber spinning. It is commonly used in appliances, automotive parts, packaging, and construction materials.

PP/PE/PS/ABS, ensuring material compatibility.

Cost-effective, eco-friendly, and ensures batch-to-batch consistency for industrial efficiency.

Definition

Black masterbatch is a color masterbatch consisting of a high concentration of pigments or additives dispersed in thermoplastic resins. It offers excellent wetting and dispersion properties, ensuring strong compatibility with colored materials.

生産プロセス

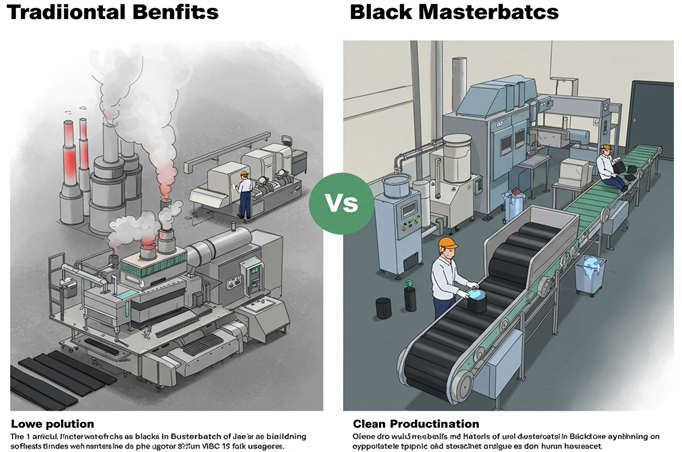

The production processes of black masterbatch include the following:

Applications of Black Masterbatch

Black masterbatch finds extensive use in various industries:

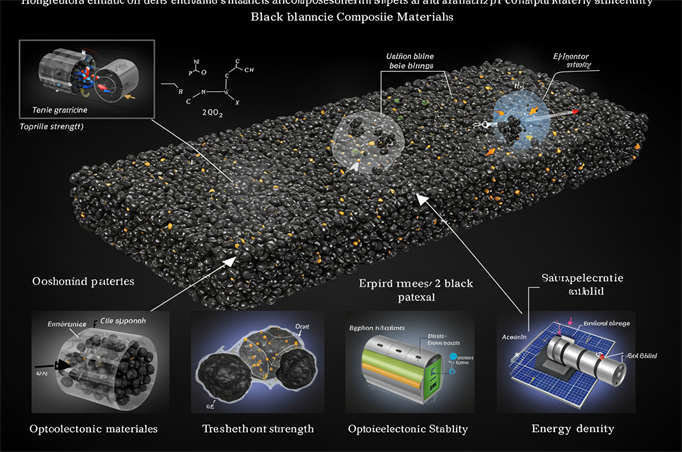

Applications in Material Science

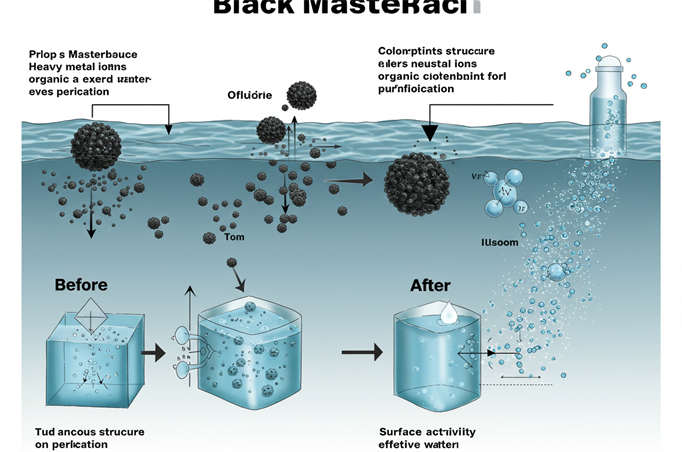

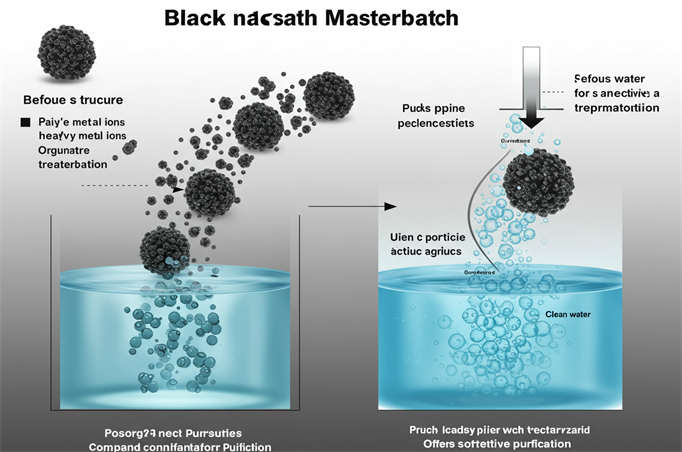

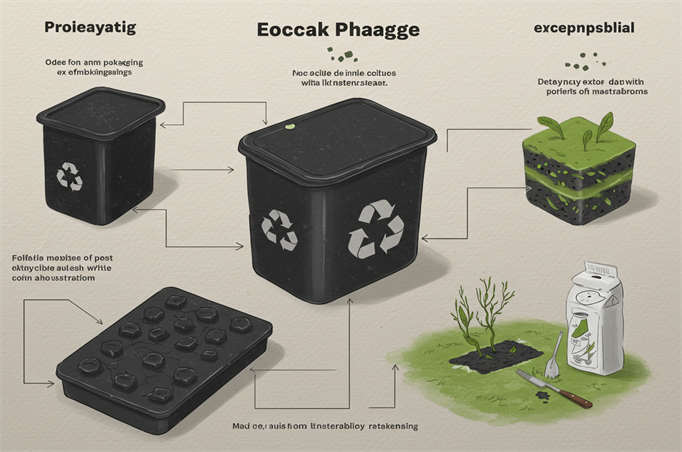

Black masterbatch plays a crucial role in environmental materials in the following ways:

Through these applications, black masterbatch plays a significant role in promoting sustainable development and environmental protection.

The application of black masterbatch in eco-friendly building materials offers the following advantages:

Black masterbatch は広く使われている in the automotive industry in the following ways:

Black masterbatch plays a significant role in the plastic processing industry with various applications:

Black masterbatch has extensive applications in the plastic processing industry. It not only fulfills the aesthetic design needs but also significantly enhances plastic products’ performance and environmental properties.

Black masterbatch is utilized in the home appliance industry in the following ways:

Black masterbatch finds widespread use in the packaging materials industry, particularly in the following areas:

In summary, black masterbatch enhances packaging materials’ appearance, functionality, and environmental impact, making it a key component in diverse packaging applications across industries.

At Fiver Star New Materials, we are a high-quality Black Masterbatch manufacturer, dedicated to providing innovative and reliable solutions for industries worldwide. With years of expertise and a commitment to excellence, we have established ourselves as a trusted partner for businesses seeking superior performance, aesthetics, and sustainability in their products. In this comprehensive guide, we will explore the versatility, benefits, and applications of our Black Masterbatch, highlighting why we are the go-to choice for global markets.

Fiver Star New Materials is a pioneering company in color masterbatch production, specializing in developing and manufacturing Black Masterbatch for diverse industrial applications. Our state-of-the-art facilities, cutting-edge technology, and rigorous quality control processes ensure that every batch of our Black Masterbatch meets the highest standards of performance and consistency.

With a team of experienced professionals and a customer-centric approach, we strive to deliver tailored solutions that address our clients’ unique needs. Whether you are in the packaging, automotive, construction, or electronics industry, our Black Masterbatch is designed to enhance your products’ functionality and visual appeal while supporting sustainable manufacturing practices.

Our Black Masterbatch is engineered to provide exceptional color consistency and uniformity, ensuring your products maintain a professional and polished appearance. The high-quality pigments and advanced dispersion technology in our production process guarantee that the color remains stable throughout the manufacturing cycle, eliminating color variation or fading issues.

Our Black Masterbatch is formulated to enhance the mechanical properties of plastic materials, including improved tensile strength, impact resistance, and wear resistance. これは makes it ideal for long-term durability and reliability applications, such as automotive components, industrial equipment, and construction materials.

At Fiver Star New Materials, we prioritize environmental sustainability and health safety. Our Black Masterbatch is produced using non-toxic, eco-friendly materials that comply with international standards and regulations. これは ensures that your products are safe for end-users and the environment, contributing to a greener future.

We understand that every client has unique requirements, so we offer fully customizable Black Masterbatch solutions. Our team works closely with you to develop formulations tailored to your specific needs, whether adjusting the color intensity, adding functional additives, or optimizing processing parameters.

Our advanced manufacturing processes and efficient supply chain management ensure that our Black Masterbatch is cost-effective and easy to integrate into your production workflow. By reducing material waste and improving processing efficiency, we help you achieve significant cost savings while maintaining high-quality standards.

Our Black Masterbatch is widely used in packaging to produce high-quality black plastic bags, boxes, and films. Its excellent light-blocking properties protect sensitive products from UV degradation, while its aesthetic appeal enhances the overall presentation of your packaging. Additionally, our eco-friendly formulations align with the growing demand for sustainable packaging solutions.

Our Black Masterbatch is trusted for producing durable and visually appealing components for automotive applications. From interior parts like dashboards and door panels to exterior elements like bumpers and trim, our masterbatch ensures consistent color and superior performance, even under extreme weather conditions. Its UV radiation and chemical resistance make it ideal for long-lasting automotive applications.

Our Black Masterbatch is used in the construction industry to manufacture pipes, profiles, and waterproofing materials. Its enhanced mechanical strength and weather resistance ensure that these materials can withstand harsh environmental conditions, providing reliable performance for years to come.

Our Black Masterbatch is popular for producing electronic enclosures, appliance housings, and other components. The sleek, modern appearance of black plastic parts and excellent electrical insulation properties make our masterbatch ideal for consumer electronics and household appliances.

Our Black Masterbatch is used in agriculture to create black mulch films and irrigation pipes. The light-blocking properties of these films suppress weed growth, while the durability of the pipes ensures efficient water distribution, contributing to higher crop yields and sustainable farming practices.

Our skilled chemists and engineers continuously research and develop new formulations to stay ahead of industry trends and customer demands. We invest heavily in R&D to ensure our Black Masterbatch remains at the forefront of technological innovation.

We adhere to strict quality control protocols, from raw material selection to final product testing, at every production stage. Our commitment to quality ensures that our Black Masterbatch consistently meets or exceeds industry standards and client expectations.

With a well-established global distribution network, we can deliver our products efficiently to clients worldwide. Our dedicated customer support team is always ready to assist you with technical inquiries, order processing, and after-sales service, ensuring a seamless experience from start to finish.

Fiver Star New Materials is committed to sustainable manufacturing practices. We strive to minimize our environmental footprint by using eco-friendly materials, optimizing energy consumption, and reducing waste. Our Black Masterbatch is designed to support your sustainability goals, helping you create high-performing and environmentally responsible products.

At Fiver Star New Materials, we are passionate about delivering high-quality Black Masterbatch solutions that enhance your products’ performance, aesthetics, and sustainability. Our extensive experience, technical expertise, and customer-focused approach make us the ideal partner for businesses across various industries.

Whether you want to improve the durability of your automotive components, create visually appealing packaging, or develop eco-friendly construction materials, our Black Masterbatch is designed to meet your needs. Contact us today to learn more about our products and how we can help you achieve your business objectives.

Fiver Star New Materials – Where Innovation Meets Excellence

購入する前に、私たちと十分なコミュニケーションを取ることをお勧めします、私たちは確かにすべての側面を考慮し、公正かつ合理的な価格プランを提供します。私たちを選択することで、あなたのお金のための最高の製品と最高の価値を得るでしょう。

The primary component of black masterbatch is polymer resin, and its cost is influenced by factors such as resin type, quality, and market price. The amount of raw materials required to produce a specific quantity of black masterbatch also directly impacts the overall cost.

Black masterbatch typically contains additives and pigments to achieve the desired characteristics and color. The costs of these additives and pigments depend on factors like their quantity, quality, and market prices. Any unique or customized requirements can also influence the final cost.

Black masterbatch's manufacturing and processing costs cover equipment maintenance, energy consumption, labor costs, and overheads. The efficiency of the production process plays a crucial role in determining the overall cost.

At Fiver Star New Materials, we invest in stringent quality control measures and testing to ensure the consistency and quality of our black masterbatch. These include raw material testing, process testing, and final product testing. The costs associated with these quality control procedures contribute to the overall cost of production.

At Five Star Materials, our DEG Aluminum Paste produced in a delicate and rigorous process. Below is our basic production process:

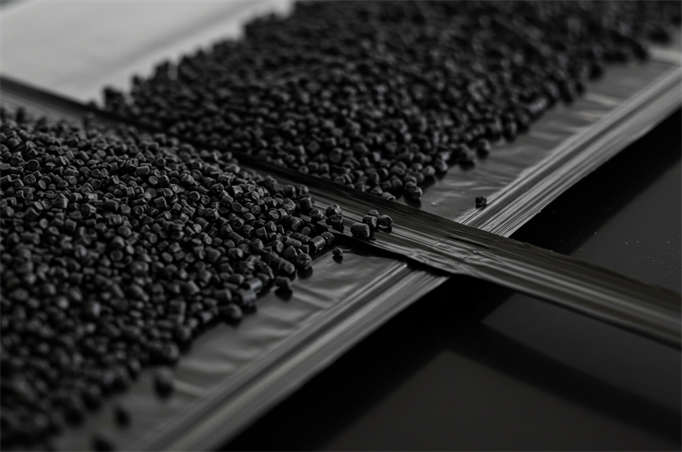

The production of black masterbatch starts with selecting the appropriate carbon black, carrier resin, and additives. The type and quality of carbon black play a crucial role in determining the final product's performance. The carrier resin must be compatible with the target plastic material. Additives such as dispersants, coupling agents, and antioxidants help improve carbon black dispersion and enhance the masterbatch's performance.

Carbon black, carrier resin, and additives are mixed in specific proportions. To achieve optimal dispersion, the mixing process must ensure that all components are evenly distributed. High-speed mixers or twin-screw mixers are typically used to facilitate the mixing process.

The mixed materials are fed into an extruder for melt extrusion. The parameters of the extruder, such as temperature, screw speed, and pressure, must be optimized based on the specific formula and equipment. The materials are blended and dispersed under high temperatures and shear forces during the melt extrusion process.

A pelletizer cuts the extruded materials into particles of a specific size, forming the black masterbatch. The pelletizing process must control the particle size and shape to meet subsequent processing and use requirements.

The produced black masterbatch undergoes quality testing, including checks for color consistency, dispersion, and mechanical properties. This ensures the product meets quality standards and customer requirements.

Key factors throughout the production process include the dispersion of the carbon black and its compatibility with the carrier resin. Good dispersion improves the masterbatch’s color strength and blackness, while compatibility affects its performance in the final plastic products. Environmental factors such as temperature and humidity must also be carefully controlled to ensure product quality.

ファイブスターマテリアルでは、すべてのプロジェクトがユニークであることを理解し、私たちの目標は、各顧客のために最高のカスタマイズされたソリューションを提供することです。