In today’s fast-paced industrial landscape, plastic coatings have become indispensable in enhancing countless products’ durability, aesthetics, and functionality across diverse sectors. From protective barriers in harsh environments to decorative finishes that captivate consumers, plastic coatings play a pivotal role in meeting the evolving demands of manufacturers and end-users. At Fiver Star New Materials, we are dedicated to pushing the boundaries of what plastic coatings can achieve.

With our extensive expertise and cutting-edge technology, we offer a comprehensive range of plastic coating products designed to cater to the unique requirements of various applications. Whether you’re looking to safeguard critical infrastructure, elevate consumer goods’ visual appeal, or optimize industrial components’ performance, our solutions are tailored to deliver exceptional results. This blog post will delve into the fascinating world of plastic coatings, exploring their diverse types, remarkable properties, and vast application possibilities.

Join us as we uncover how plastic coatings, including specialized additives like aluminum silver paste, are revolutionizing industries and setting new standards for quality and performance. Stay tuned to discover how Fiver Star New Materials is at the forefront of this exciting journey, providing you with the tools and knowledge to stay ahead in a competitive market.

At Five New Materials, we understand the crucial role of high-performance coatings in various industries. This exploration delves into plastic coatings, their diverse types and applications, and how our innovative aluminum silver paste significantly enhances their performance.

What is a Plastic Coating?

A plastic coating involves applying a layer of synthetic resin onto a substrate to impart specific properties like protection, decoration, or functionality. Let’s examine some common types:

Epoxy Resin Coatings

Functional Characteristics: Epoxy resin coatings exhibit excellent adhesion to various substrates, including metals and concrete. They provide robust chemical resistance against acids, alkalis, and salts. Furthermore, their superior insulation properties effectively prevent electrical leakage.

Applications: We see widespread use of epoxy coatings as linings for pipes and reaction vessels in the chemical industry, preventing corrosion from harsh materials. In electronics, they serve as vital insulating and protective layers for circuit boards and other equipment.

Polyester Coatings

Functional Characteristics: Polyester coatings demonstrate good weather resistance, allowing long-term outdoor exposure and protection against UV radiation, wind, and rain. Their decorative versatility enables various colors and gloss levels, enhancing the aesthetic appeal. Additionally, polyester coatings possess significant hardness and abrasion resistance.

Applications: These coatings frequently enhance the appearance of building exteriors, such as color steel tiles and aluminum doors and windows. They also find extensive use on appliance housings, providing a glossy finish and a degree of protection.

Polyurethane Coatings

Functional Characteristics: Polyurethane coatings offer excellent flexibility, enabling them to withstand substrate bending without cracking. Their abrasion resistance makes them suitable for surfaces subject to frequent friction. Moreover, they maintain good flexibility even in low-temperature environments, preventing brittleness.

Applications: We find polyurethane coatings on fitness equipment surfaces, like bicycle frames and exercise machines, providing durability and a comfortable touch. They also protect automotive components, such as undercarriage coatings, resisting stone chips and road chemicals.

Fluorocarbon Coatings

Functional Characteristics: Fluorocarbon coatings boast exceptional weather resistance and are often hailed as the “king of coatings” for their long-term defense against UV radiation, heat, and smog. They exhibit high chemical inertness, resisting reactions with other substances. Their strong, self-cleaning properties prevent the adhesion of dust and other pollutants.

Applications: These coatings primarily protect the facades of high-rise buildings, including glass and metal curtain walls, ensuring a perpetually clean and new appearance. They also enhance the durability of outdoor signs and other installations requiring superior weather resistance.

Ethylene-Vinyl Acetate Coatings (EVA Coatings)

Functional Characteristics: EVA coatings offer good flexibility and accommodate the bending and flexing of the substrate. They provide good water and chemical resistance against common liquids and substances.

Applications: We often see EVA coatings as insulation and protective layers for wires and cables, safeguarding internal conductors from external environmental factors. They also function as inner layers in some packaging materials, providing a barrier against external elements.

Aluminum Silver Paste in Plastic Coatings

At Five New Materials, we recognize aluminum silver paste as a crucial additive that imparts unique metallic effects and enhances various performance attributes in plastic products.

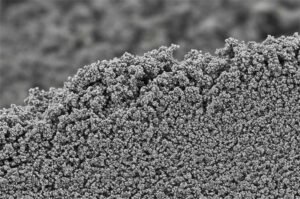

Properties, Metallic Texture, and Decoration: The aluminum powder’s high surface gloss and reflectivity in our silver paste enable plastic products to exhibit stunning metallic textures, significantly improving their visual appeal and decorative quality. これは makes them ideal for appliance housings and toys, increasing their attractiveness.

Coverage and Reflection: Our aluminum silver paste offers excellent hiding power for substrate color defects. It effectively reflects light and heat rays, enhancing the coating’s opacity and brilliance, producing a more refined and lustrous surface.

Weather Resistance and Corrosion Resistance: Specially treated aluminum silver paste provides good weather and corrosion resistance, offering long-term protection in harsh environments. これは extends the lifespan of plastic products by preventing the penetration of gases, water, and UV radiation, thus safeguarding the coating.

Flow and Thixotropy: Our aluminum silver paste exhibits strong flow and thixotropic properties, making application and wiping easy and efficient. This ensures a uniform coating and prevents sagging issues.

Types and Application Scenarios:

- Floating Aluminum Silver Paste: The aluminum flakes in this type float on the coating surface, creating a sparkling effect. It is suitable for plastic products like toys and decorations that require a firm metallic texture and luster, enhancing their visual impact.

- Non-Floating Aluminum Silver Paste: The aluminum flakes align uniformly and parallel within the coating. This type blends well with various pigments, primarily for systems requiring a unique metallic feel or multi-color effects with a certain degree of brightness and hue. It’s ideal for automotive plastic components and appliance housings where coating appearance and properties are critical.

- Electroplating Imitation Series Aluminum Silver Paste: Our fine-particle silver paste in this series provides an excellent metallic feel and hiding power with high fineness. It’s perfect for spraying plastic products to achieve an imitation metal plating effect, commonly used in manufacturing mobile phone cases and other electronic device housings.

- Heat-resistant aluminum Silver Paste suits coating systems requiring high-temperature curing, such as automotive original paint and coil coatings. It offers a strong sparkling and flop effect, withstanding high temperatures while maintaining the coating’s integrity and aesthetics.

How Aluminum Silver Paste Enhances Weather Resistance in Plastic Coatings

At Five New Materials, we understand that enhancing the durability of plastic coatings is paramount. Our aluminum silver paste contributes significantly to weather resistance through the following mechanisms:

Inherent Properties: The high reflectivity of the aluminum powder in our silver paste effectively reflects UV radiation. これは reduces the direct exposure of the plastic substrate to UV rays, minimizing UV-induced degradation and fading, thereby improving the overall weather resistance of the plastic coating.

Encapsulation Treatment:

- Silica Encapsulation: We utilize silica encapsulation for our aluminum silver paste, which significantly enhances its water and acid-alkali resistance, consequently boosting weather resistance. For example, Yantai Yunfan’s Silver Arrow Yantai waterborne floating aluminum paste, treated with silica encapsulation, demonstrates excellent weather and acid-alkali resistance.

- Resin Encapsulation: The paint film can maintain long-term gloss and color stability under extreme environmental conditions through innovative resin encapsulation technologies, such as those employed in Silver Arrow aluminum silver paste. これは protects the substrate from UV radiation and salt spray corrosion, significantly improving the coating’s weather and corrosion resistance.

Enhanced Compatibility with Resins:

Selecting the appropriate resin system that exhibits excellent compatibility with our aluminum silver paste allows the paste to exert its properties within the plastic coating better, enhancing its weather resistance. For instance, the aluminum silver paste used in fluorocarbon coatings is compatible with fluorocarbon resins, significantly improving the coating’s durability.

Addition of Additives:

We can further modify our aluminum silver paste by incorporating specific additives like nano-bentonite and multi-walled carbon nanotubes to enhance weather resistance. For example, in methods to improve the gloss effect of weather-resistant aluminum silver paste, the addition of nano-bentonite and multi-walled carbon nanotubes, followed by specific processing techniques, enables the aluminum silver paste to withstand temperatures of 530-550°C and resist corrosion for 200 hours while maintaining good metallic gloss and hiding power.

How to Quantify the Anti-Aging Effect of Aluminum Silver Paste on Plastic Coatings

At Five New Materials, we believe in providing quantifiable data to demonstrate the effectiveness of our products. We analyze the anti-aging effects of our aluminum silver paste on plastic coatings through the following rigorous testing methods:

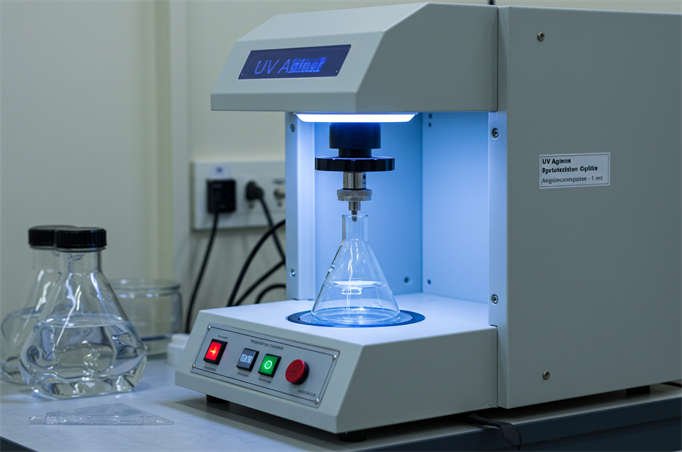

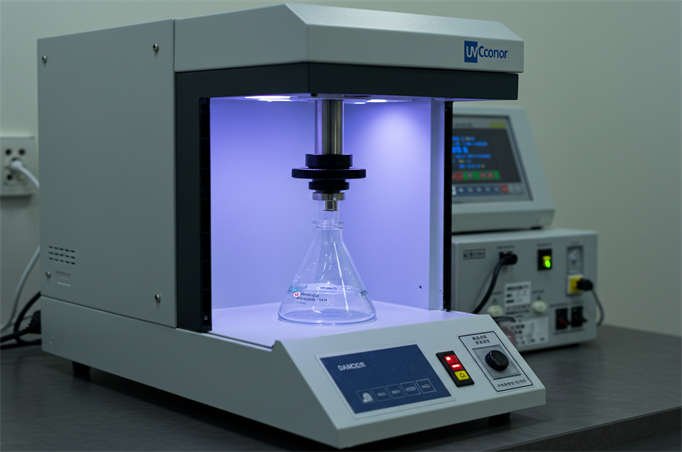

Artificial Climate Accelerated Aging Tests

- Xenon Arc Lamp Aging Test: We conduct comparative tests on plastic coatings with and without our aluminum silver paste by simulating sunlight’s full spectrum UV radiation and varying temperature and humidity conditions. The xenon arc lamp aging test allows precise control over test parameters. For example, following GB/T 1642.3-1997 standards, we set a black panel temperature of (60±3)°C, an air humidity of (65±5)%, and a radiation intensity of (550±50) W/m². We then evaluate samples after predetermined durations like 1000 hours and 2000 hours.

- Ultraviolet Aging Test: We utilize UV aging test chambers, accelerating material degradation through high-intensity UV radiation. For instance, adhering to ASTM G154 standards, we use UVA-340 lamps, set the temperature at (60±3)°C and humidity at (50±5)%, and assess sample appearance and technical parameters after 500 and 1000 hours.

Outdoor Natural Exposure Tests

- Selecting Appropriate Locations: We conduct outdoor exposure tests in regions with high humidity, high temperatures, and high UV radiation, such as Hainan. Samples of plastic coatings with and without our aluminum silver paste undergo simultaneous outdoor exposure, and we record changes in their properties at different time intervals.

- Time Cycles: We typically set different exposure periods, such as 6 months, 1 year, and 2 years, directly observing changes in sample appearance like gloss loss, discoloration, and delamination and conducting technical parameter testing.

Salt Spray Resistance Test

- Salt Spray Test Standards: Following GB/T 10125-2013 standards, we prepare a 5% NaCl solution and place test samples in a salt spray chamber, maintaining a test temperature of (35±2)°C with continuous spraying for durations like 240 hours and 480 hours.

- Result Comparison: By comparing data such as mass loss rate and adhesion of samples with and without aluminum silver paste after the salt spray test, we quantify the anti-aging effect of our product.

Resistance to Chemical Substances Test

- Selecting Chemical Compounds: We choose various chemical compounds, including acids (sulfuric acid, hydrochloric acid, etc.), alkalis (sodium hydroxide, potassium hydroxide, etc.), and salts (sodium chloride, potassium chloride, etc.), and prepare solutions of specific concentrations, such as 5% and 10%.

- Immersion Test: We immerse test samples separately in different chemical solutions for 24 hours, 48 hours, and 72 hours, observing changes in sample appearance and testing technical parameters like strength and hardness.

Adhesion Test

- Testing Standards: We employ cross-cut or pull-off tests to evaluate the adhesion of plastic coatings with and without our aluminum silver paste. According to GB/T 9286-1998 standards for the cross-cut test, we create a grid pattern on the sample surface, apply and remove adhesive tape, and observe the coating detachment within the grid area. We also use adhesion testers to measure the maximum force required to pull the coating from the substrate.

- Result Comparison: By conducting adhesion tests on samples after various weathering tests and recording changes in adhesion values, we quantify the effectiveness of our aluminum silver paste in maintaining coating adhesion.

Glossiness Inspection

- Testing Equipment: We use gloss meters to inspect the surface gloss of test samples, following GB/T 9754-2007 standards. We measure the gloss values of samples with and without aluminum silver paste before and after testing at different angles, such as 20°, 60°, and 85°.

- Result Comparison: By measuring the gloss retention rate of samples after each weathering test and comparing the gloss retention rates of different samples, we quantify the effect of our aluminum silver paste on enhancing coating gloss.

Inspecting Color Change

- Testing Equipment: We utilize spectrophotometers or color difference meters to analyze the color of test samples, adhering to GB/T 11543-1989 standards. We record the color parameters of the samples, such as L*, a*, and b* values.

- Result Comparison: After various weathering tests, we remeasure the color parameters of the samples and calculate the color difference ΔE. By comparing the color change of samples with and without aluminum silver paste after each test, we can quantify the effectiveness of our product in improving color retention.

At Five New Materials, we are committed to providing high-quality aluminum silver paste that significantly enhances the performance and longevity of plastic coatings. Our rigorous testing procedures ensure that our materials meet the highest durability and aesthetic appeal standards.

As we conclude this enlightening exploration of plastic coatings, it’s evident that these innovative materials are transforming industries by offering unparalleled protection, aesthetics, and functionality. From epoxy resins and polyurethane coatings to the remarkable properties of aluminum silver paste, the possibilities for enhancing plastic products are vast and exciting. At Fiver Star New Materials, we take pride in being at the forefront of this dynamic field. Our commitment to excellence is reflected in the vast array of high-quality plastic coatings and additives we provide. We understand that each application has its unique challenges, so we continuously strive to develop solutions that meet and exceed industry standards. Our aluminum silver paste, for instance, exemplifies our dedication to innovation, offering enhanced durability, corrosion resistance, and a distinctive metallic finish that adds value to countless products. When you choose Fiver Star New Materials, you’re not just selecting a supplier but partnering with a team of experts passionate about helping you achieve your goals. We invite you to explore our extensive product portfolio and discover how our plastic coating solutions can elevate your projects to new heights. Together, let’s continue to push the boundaries of what’s possible in plastic coatings, creating a future where innovation knows no limits. Thank you for joining us on this journey of discovery, and we look forward to being your trusted companion in the ever-evolving landscape of plastic coating technology.