At Five Star New Materials, we understand that the beauty of a car lies not just in its design but in the way it catches the light, turns heads, and stands the test of time. Automakers and consumers have sought the perfect balance of aesthetics and durability in automotive coatings for decades. Today, that balance is achieved through the innovative use of car paint sparkle—a term that encapsulates the brilliance, depth, and allure of modern automotive finishes. At the heart of this transformation lies silk light aluminum paste (also known as aluminum silver paste), a premium metallic pigment engineered to elevate car paint’s visual and functional performance.

Silk light aluminum paste is more than just a pigment; it is a testament to precision engineering and cutting-edge material science. Composed of snowflake-like aluminum particles and specialized solvents, this advanced material delivers unparalleled light reflection, metallic luster, and durability. Integrating into automotive coatings creates a mesmerizing visual effect that enhances the vehicle’s appearance while providing critical protection against environmental stressors.

But what makes silk light aluminum paste genuinely exceptional is its versatility. Whether used in car paint sparkle finishes for original equipment manufacturer (OEM) coatings or refinishing applications, this material delivers consistent, high-impact results. From enhancing gloss and texture to creating dynamic color-shifting effects, silk light aluminum paste transforms ordinary paint into a canvas of brilliance.

We are proud to be at the forefront of this innovation at Five Star New Materials. Our silk light aluminum paste solutions are designed to meet the rigorous demands of the automotive industry, offering superior performance in OEM paints, repair coatings, wheel finishes, and even eco-friendly water-based systems. As environmental regulations tighten and consumer expectations rise, our commitment to sustainability and quality ensures that our products meet and exceed industry standards.

This article delves into the science, art, and application of silk light aluminum paste in automotive coatings. We explore how it enhances car paint sparkle, improves durability, and addresses the unique challenges of OEM and repair environments. Whether you are an automaker seeking cutting-edge materials or a refinisher looking to restore vehicles to their original glory, this guide will explain why silk-light aluminum paste is the cornerstone of modern automotive finishes.

Silk Light Aluminum Paste, or aluminum silver paste, is a metal pigment produced through specialized production processes and surface treatments. Its main components are small aluminum particles and solvents, offering excellent light reflection and metallic texture. Widely used in automotive coatings, silk light aluminum paste significantly enhances the performance and appearance of automotive finishes. Below are some of its practical applications in automotive paints:

Enhancing Gloss and Texture

Improved Gloss:

Silk light aluminum paste contains aluminum flakes that efficiently reflect light sources, much like countless tiny mirrors. This reflection showcases a dazzling shine, making the car’s body appear more refined and glamorous under sunlight or artificial lighting, ultimately elevating the car’s overall aesthetic and sense of luxury.

Creating Special Effects:

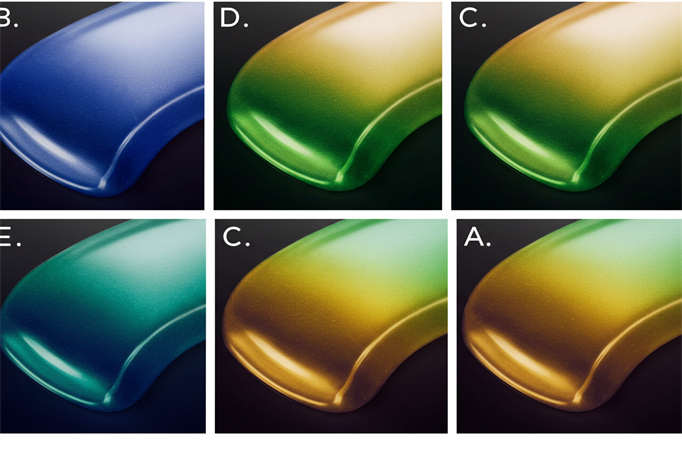

When mixed with transparent color pigments, silk light aluminum paste allows light to pass through, project, or reflect off the paint layer. これは creates a unique effect where the paint color changes depending on the viewing angle, adding more depth and coolness to the car’s appearance.

Enhancing Coating Properties

Improved Durability and Corrosion Resistance:

The metallic components of silk light aluminum paste help block the leakage of moisture and oxygen, improving the corrosion resistance of automotive coatings. これは prolongs the vehicle’s lifespan. Additionally, its weather resistance protects the paint from UV damage, reducing the risk of fading and aging.

Better Coverage and Whitening Effect:

Silk light aluminum paste offers superior hiding power, effectively concealing defects and the underlying color of the car’s surface, resulting in a more even and polished finish. Its whitening effect also makes the paint appear fresher and brighter.

Strong Adhesion and Wear Resistance:

Silk light aluminum paste provides strong adhesion, ensuring the paint stays firmly attached to the car body, even in gaps, and prevents peeling. Its excellent wear resistance protects the paint from daily driving wear and tear, including scratches.

Practical Applications in Automotive Coatings

Original Paint:

High-quality silk light aluminum paste products, such as silver round or silver round aluminum paste, offer a strong sparkle effect and special effects, making them suitable for original automotive paints. These products provide a metallic feel and decorative appearance, enhancing the vehicle’s overall design.

Vehicle Repair Paint:

In vehicle repair paints, silk light aluminum paste significantly improves the quality and appearance of the repaired paint, allowing it to match the original finish. It makes the repaired areas look as good as new, seamlessly blending with the original paint.

Car Wheel Hub Paint:

Imitation electroplated aluminum silver paste is commonly used in wheel hub coatings. It mimics the traditional electroplating metallic feel while providing better environmental friendliness and durability.

Water-Based Automotive Coatings:

With the rise of environmental regulations, water-based aluminum silver paste development and application have become an important direction for the automotive coating industry. Water-based aluminum silver paste not only inherits the excellent performance of traditional aluminum silver paste but also boasts superior environmental properties, meeting sustainable development requirements.

Differences in Aluminum Paste Use for Original and Repair Paints

1. Material Characteristics and Requirements

- Original Paint: Original automotive paints require high-quality aluminum paste with high granularity, symmetrical particle size, excellent purity, and stability. Since original paints undergo high-temperature baking (typically above 130°C), the aluminum paste’s high-temperature resistance is crucial.

- Repair Paint: Aluminum paste used in repair paints must meet specific requirements for particle size, coverage, and granularity. However, repair paints are usually cured at lower temperatures (around 80°C) or air-dried, making heat resistance less critical.

2. Coating Structure and Process

- Original Paint: Original automotive coatings consist of electrophoretic layers, intermediate layers, topcoats, and surface coatings. Aluminum paste is widely used in topcoats to provide even metallic texture and decorative finishes. Automatic spray equipment is typically used to ensure even distribution and strong adhesion.

- Repair Paint: Repair coatings usually consist of only partial layers, topcoats, and surface coatings and often lack an electrophoretic layer. Manual application of repair paint may lead to uneven distribution and weaker adhesion of aluminum paste.

3. Performance

- Original Paint: Due to high-temperature baking and strict process controls, aluminum paste in original paints offers stronger adhesion, better corrosion resistance, and improved scratch resistance, providing more durable decorative finishes.

- Repair Paint: Aluminum paste in repair coatings may have slightly lower durability and adhesion, and in complex construction conditions, issues such as color discrepancies and orange peel may arise.

4. Primary Uses

- Original Paint: Used primarily in car production, original paints require high-quality coatings that meet stringent temperature and application standards.

- Repair Paint: Used for repairing damaged car finishes, repair paints offer more flexibility but cannot achieve the same effects as original paints due to material and process limitations.

The main differences in aluminum paste usage between original and repair paints are material quality, process standards, performance, and primary applications. Original paint aluminum paste prioritizes high-temperature stability and decorative finishes, while repair paint aluminum paste focuses on construction convenience and cost control.

Bonding Differences Between Repair and Original Paint Aluminum Paste

The differences in aluminum paste bonding between repair and original automotive paints are as follows:

Baking Temperature:

Original paint undergoes high-temperature baking, at least at 130°C, which strengthens the bond between the aluminum paste and the paint layer. Repair paint is typically baked at lower temperatures (around 80°C), weakening bonds.

Topcoat Process:

Original paint uses electrophoretic methods, providing strong adhesion and corrosion resistance. In contrast, repair paint often uses phosphating treatment, resulting in lower adhesion and corrosion resistance than original paint.

Material Quality:

The aluminum paste used in the original paint is of higher quality, providing excellent bonding. Repair paints use aluminum paste of lower quality, which may lead to reduced adhesion.

Application Process:

Original paints are applied using automatic spray equipment, ensuring even distribution and firm adhesion of aluminum paste. Repair paints are often applied manually, which may result in uneven distribution and lower adhesion.

Original paint has a clear advantage in aluminum paste bonding due to higher baking temperatures, electrophoretic processes, superior material quality, and automated application.

How Does Aluminum Paste Quality Affect Adhesion?

The quality of aluminum paste directly impacts adhesion. Here is a detailed analysis:

Aluminum Paste Characteristics

- カバレッジ: If the aluminum paste lacks good coverage or the low-quality aluminum paste is chosen, the bonding strength will be compromised during the blending process.

- Formula Rationality: The proportion of aluminum paste in the formula or excessive use of silicon additives can cause silver flake shedding, weakening the adhesion.

- Resin Selection: If the chosen resin does not encapsulate the aluminum paste effectively, silver flakes will detach during handling or application, reducing adhesion.

Physical Characteristics of Aluminum Paste

- Particle Size and Distribution: The size and uniformity of the aluminum paste particles affect its water permeability and contact surface with the substrate. Larger particles lead to uneven distribution, which damages adhesion, while smaller particles increase costs and complicate handling.

- 純度: The higher the purity of the aluminum paste, the fewer impurities it contains, resulting in better compatibility with the paint and stronger adhesion. Excessive residuals can weaken the fusion between aluminum paste and paint, reducing adhesion.

- 安定性: The reliability of aluminum paste during storage and usage, including resistance to clumping or mold formation, can affect its performance and adhesion.

Compatibility Between Aluminum Paste and Paint

The compatibility between aluminum paste and paint is a key factor for adhesion. Poor compatibility prevents the aluminum paste from dispersing evenly, leading to uneven coatings and reduced adhesion. Good mixing performance enhances the uniform distribution of aluminum paste within the paint system, improving both adhesion and overall performance.

Surface Treatment of Aluminum Paste

Aluminum paste undergoes surface treatments to enhance its compatibility and adhesion. Specific resin coatings or additives improve wettability, permeability, and adhesion, thus boosting overall performance.

Drying and Curing Characteristics

The drying and curing characteristics of aluminum paste also play a vital role in adhesion. Over-drying can create stress between the paint film and substrate, weakening adhesion. Poor or rapid curing can also impair the fusion between aluminum paste and paint, reducing adhesion.

The quality of aluminum paste significantly influences adhesion through its physical properties, compatibility with the paint, and the drying and curing process. High-quality aluminum paste leads to better adhesion, while inferior paste may compromise the finish and durability.

The world of automotive coatings is constantly evolving, driven by advancements in material science, environmental regulations, and consumer demand for beauty and longevity. At Five Star New Materials, we are dedicated to pushing the boundaries of what is possible with car paint sparkle. Our silk light aluminum paste solutions are not just products—they result from decades of research, innovation, and collaboration with industry leaders.

The difference is evident when you see a car painted with our aluminum paste. The vehicle paint sparkle effect created by our premium pigments is unmatched, offering a combination of brilliance, depth, and durability that sets vehicles apart. Whether you are working with OEM coatings, repair paints, wheel finishes, or water-based systems, our solutions are designed to exceed expectations.

But our commitment doesn’t stop at performance. As environmental sustainability becomes a priority for automakers and consumers, we proudly offer eco-friendly alternatives without compromising quality. For example, our water-based aluminum silver paste retains traditional products’ exceptional light reflection and metallic luster while reducing environmental impact. This balance of performance and sustainability sets Five Star New Materials apart.

We understand that every application has unique requirements. That’s why we offer tailored solutions for OEM and repair environments. Our high-quality aluminum paste for OEM paints ensures exceptional car paint sparkle and durability, while our repair-friendly options provide the flexibility and cost-effectiveness needed for refinishing work. Whether you need to enhance gloss, create dynamic color effects, or improve corrosion resistance, our products deliver results you can see and feel.

We supply pigments at Five Star New Materials and partner with you to achieve your goals. Our technical expertise, rigorous quality control, and customer-focused approach ensure you receive the support you need to succeed. As you explore the possibilities of silk light aluminum paste in automotive coatings, we invite you to experience the difference that Five Star New Materials can make.

Ready to elevate your car paint sparkle? Contact us today to learn more about our premium silk light aluminum paste solutions and discover how we can help you achieve the perfect balance of aesthetics, performance, and sustainability. Your vision, our innovation—let’s drive the future of automotive finishes together.