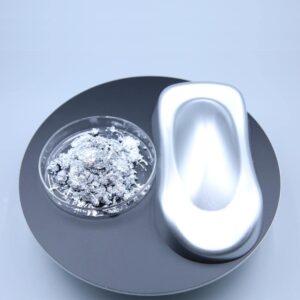

About Plastic Coating Aluminum Paste

A highly innovative coating that provides an anti-corrosive layer and decorative finish for a wide range of plastic products is the plastic coating aluminum paste from Five Star Materials. The coating is an ideal option for its number of benefits such as aesthetics, durability, heat reflection, and more.

To optimize the use of the plastic coating aluminum paste a few things to keep in mind are the following; surface preparation, application method, and curing time. The surface of the application should be free from dirt, grease, and other contaminants. Some of the common examples of applying the paste is by brushing, rolling, or spraying which would later on require a certain amount of time for curing before it is fully dry.

Once applied to a plastic surface the assurance of durable coating and protection from corrosive elements are increased with an elegant look or finish.