The high-quality vacuum metalized pigments are made of flake-like aluminum particles that creates a mirror-like finish on a variety of substrates. Often it is used in applications including plastics, metals, and paper surfaces in appliances, types of furniture, and other products.

It is produced by taking the pigment of aluminum in a process called physical vapor deposition (PVD), the metal is generally vaporized in a vacuum chamber to create extremely thin flakes of aluminum.

When looking for a partner, you need uniqueness, quality, and technological leadership. Five Star Materials stands at the forefront of the global aluminum pigment industry with its outstanding spirit of innovation, top-notch product quality, and continuous pursuit of superior technology. Our sophisticated products are widely applied from car manufacturing to electronic product production. Our strength originates from advanced management ideas and a close fusion of technological innovation and sustainable development. Choosing us means choosing top-tier products, outstanding services, and first-class technology. Five Star Materials, outstanding because of you!

The high-quality vacuum metalized pigments are made of flake-like aluminum particles that creates a mirror-like finish on a variety of substrates. Often it is used in applications including plastics, metals, and paper surfaces in appliances, types of furniture, and other products.

It is produced by taking the pigment of aluminum in a process called physical vapor deposition (PVD), the metal is generally vaporized in a vacuum chamber to create extremely thin flakes of aluminum. The thickness of vacuum metalized pigments can range from 0.1 to 0.3 micrometers which are blended in coatings such as clear resin.

There are several benefits of using vacuum metallized pigments mainly safety from its non-toxic properties made from recycled aluminum which is environmentally friendly. Additionally, the vacuum metalized pigments have an aesthetic finish, colorfastness that prevents discoloration over time, and durability to withstand a variety of environmental conditions.

At Five Star Materials, we have always focused on continuous quality improvement, providing superior products and an outstanding customer service experience.

Five Star Materials newly developed Vacuum Metalized Pigments is made from high purity raw materials, which are processed using a unique technology to form silver-white flake-like particles with uniform particle size distribution. Compared with ordinary silver-like paste, it presents a stronger sense of lustre and metallic texture, and can achieve excellent tone levels. After application, the effect is more delicate and elegant, with strong visual brightness.

With regard to quality assurance, our suppliers are selected after strict screening to ensure that we obtain high-purity, high-quality raw materials. The production process is subject to standardised quality control, and each step of the process meets the quality requirements. We have a professional testing team to conduct a comprehensive inspection of the products, such as particle size distribution, purity, gloss and other indicators. Only products that have passed a series of quality tests can leave the factory.

Five Star Materials also attach great importance to after-sales service. If there is any problem in the use, customers can contact our service team for support at any time, and we will provide the best solution. If you are not satisfied with the product, we will accept the return unconditionally.

Quality is at the core of our culture, and all our employees strive to improve the quality of our products to meet the needs of our customers. We value customer feedback as a driver for continuous improvement.

Five Star Materials understand the importance of choosing quality suppliers. We hope you will give us the opportunity to let our products and services prove our quality and professionalism. We are confident that after your experience, you will be positively impressed with our Vacuum Metalized Pigments.

We suggest you to communicate with us fully before purchasing, we will certainly consider all aspects and provide a fair and reasonable price plan. By choosing us, you will get the best product and the best value for your money.

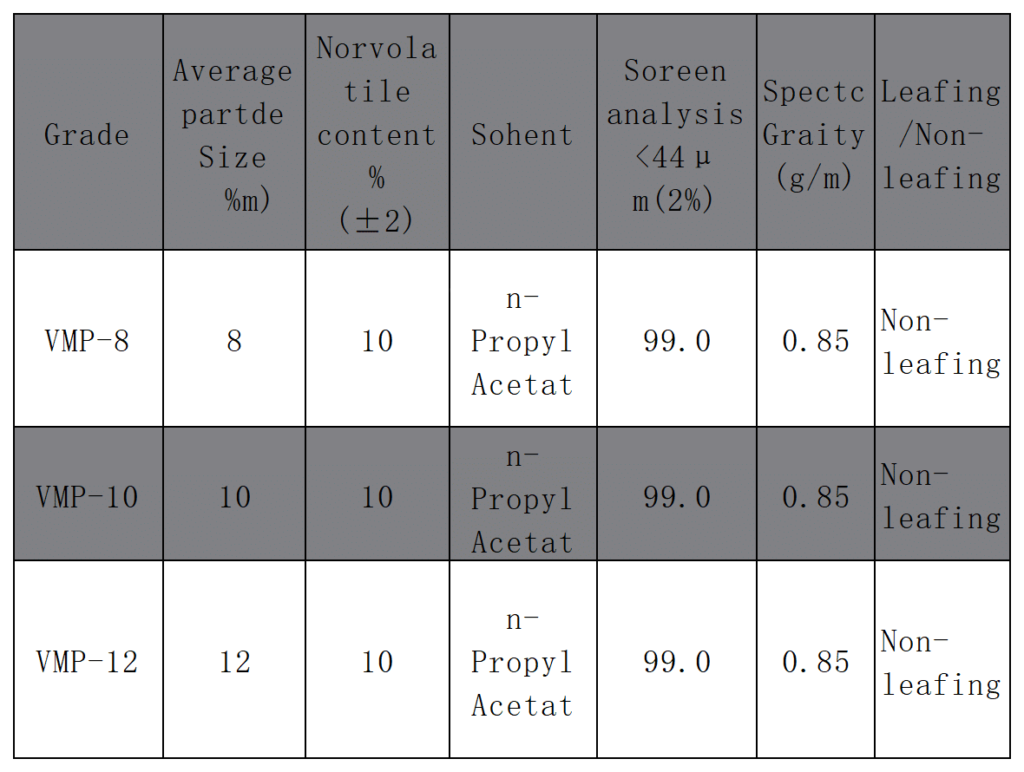

Choosing the right size of product gives you the best value for money. Our Vacuum Metalized Pigments is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

The larger the quantity purchased, the lower the unit price will be. Bulk orders allow us to better share our production and operating costs, so we are happy to offer discounted prices for bulk purchases.

The timing and method of payment you choose will also affect the price. For example, paying in full upfront can result in a more favourable price, as it reduces our cost of capital. Please discuss the most suitable payment option with our sales team.

Transport and logistics are also factors that affect the total cost of ownership. Different modes of transport and destinations will incur different shipping costs. Duties, insurance and other costs also need to be taken into account. By calculating these factors in advance of purchase, you can more accurately estimate the total cost.

At Five Star Materials, our Vacuum Metalized Pigments is produced in a delicate and rigorous process. Below is our basic production process:

We purchase high purity raw materials from trusted suppliers to ensure the quality of our products from the source.

The raw material is crushed to convert the aluminium blocks into tiny particles for subsequent processing.

The crushed aluminium powder is mixed with our specially formulated solvents and additives and then blended through a high speed mixing process. This step is very important as it determines the stability of the aluminium paste and the shape of the particles.

After grinding, the aluminium paste is passed through a filtration system to remove possible impurities. Our quality control team will then carry out a series of tests on the product, such as particle size, gloss, metallic feel, etc., to confirm that the product meets our high quality standards.

Products that have passed rigorous testing are carefully packaged and then stored in our warehouses, ready for shipment to our customers.

Please note that this is a basic production process and the exact process may vary depending on the specific requirements of the product. At Five Star Materials, we take quality control very seriously and ensure that our products meet our strict quality standards at every step of the production process.

At Five Star Material, we understand that every project is unique, and our goal is to provide the best customized solutions for each customer.

We will contact you within 24 hours.

For your urgent inquiries,please contact us through whatsapp No. : +86-13309617918