A pasta de alumínio com revestimento plástico confere aos plásticos um aspecto metálico. Também ajuda a protegê-los bem. Os tipos de folhas fazem com que as coisas pareçam brilhantes como um espelho.. No entanto, estes podem perder partículas com o passar do tempo. Os tipos não folhosos têm um brilho mais suave. São mais duradouros e resistentes. As pastas à base de água são mais seguras de usar. Além disso, poluem menos. O mercado das pastas de alumínio valia 685,75 milhões de dólares americanos em 2024. Os revestimentos são a forma mais comum de utilização.

| Segmento | Valor/Ação |

|---|---|

| Tamanho do mercado (2024) | 685,75 milhões de dólares americanos |

| Uso principal | Revestimentos (54.8%) |

| Região líder | Ásia-Pacífico |

Principais conclusões

- A pasta de alumínio com revestimento plástico dá aos plásticos um aspecto brilhante e semelhante ao metal. Também esconde riscos e melhora a aparência dos objetos. A pasta mantém a água, o ar e os produtos químicos afastados dos plásticos. Isso ajuda os produtos a durarem mais tempo e a permanecerem resistentes. A pasta de alumínio ajuda a refletir a luz e bloqueia os raios UV. Isso a torna ideal para locais ao ar livre e bem iluminados. Existem muitos tipos e tamanhos de flocos de alumínio. Isso permite que as pessoas escolham a aparência e a resistência dos objetos em diferentes trabalhos. É importante use a pasta com segurança e escolha o tipo certo. Isso ajuda a evitar problemas e mantém os trabalhadores e a natureza seguros.

Benefícios da pasta de alumínio com revestimento plástico

Aparência e efeito metálico

A pasta de alumínio com revestimento plástico faz com que o plástico pareça metal. As escamas de alumínio refletir a luz que você pode ver e a luz que você não pode ver. Isso confere um aspecto brilhante e branco prateado, semelhante ao metal verdadeiro. Os flocos têm formas diferentes e refletem a luz de várias maneiras. Isso faz com que a superfície pareça brilhante e tridimensional.

- A pasta cobre a cor sob o plástico. Ela esconde pequenos arranhões e marcas.

- A camada lisa das escamas de alumínio reflete mais luz. Isso torna o acabamento ainda mais brilhante.

- A forma como os flocos se misturam com o revestimento confere um toque metálico especial. O efeito parece mais forte sob certas luzes.

A pasta de alumínio com revestimento plástico é diferente de outros aditivos metálicos. Ela proporciona um acabamento brilhante e cintilante. Isso melhora a aparência de brinquedos, peças automotivas e eletrônicos. Existem diferentes tipos de pasta. Algumas dão brilho espelhado. Outras conferem uma aparência suave de metal escovado. Esses efeitos duram mais e mantêm melhor a cor do que outros revestimentos.

Dica: Muitos fabricantes utilizam esta pasta porque ela esconde bem as imperfeições e proporciona um aspecto suave e elegante.

Barreira e proteção

A pasta de alumínio com revestimento plástico faz mais do que apenas deixar as coisas com boa aparência. Ela também protege as superfícies plásticas contra danos. As escamas de alumínio formam uma camada protetora que bloqueia a água, o ar e a sujeira. Essa camada ajuda a impedir que o plástico se quebre ou mude de cor.

- O revestimento impede a entrada de água e ar. Isso evita que os plásticos rachem ou desbotem.

- Ele impede que muitos produtos químicos e poluentes entrem em contato com o plástico.

- A proteção ajuda os produtos a durarem mais, mesmo em locais difíceis.

Essa proteção é importante para itens como embalagens de alimentos, cadeiras de exterior e peças automotivas. A pasta ajuda esses itens a permanecerem resistentes e com aparência de novos por muito tempo.

Refletividade e resistência aos raios ultravioleta

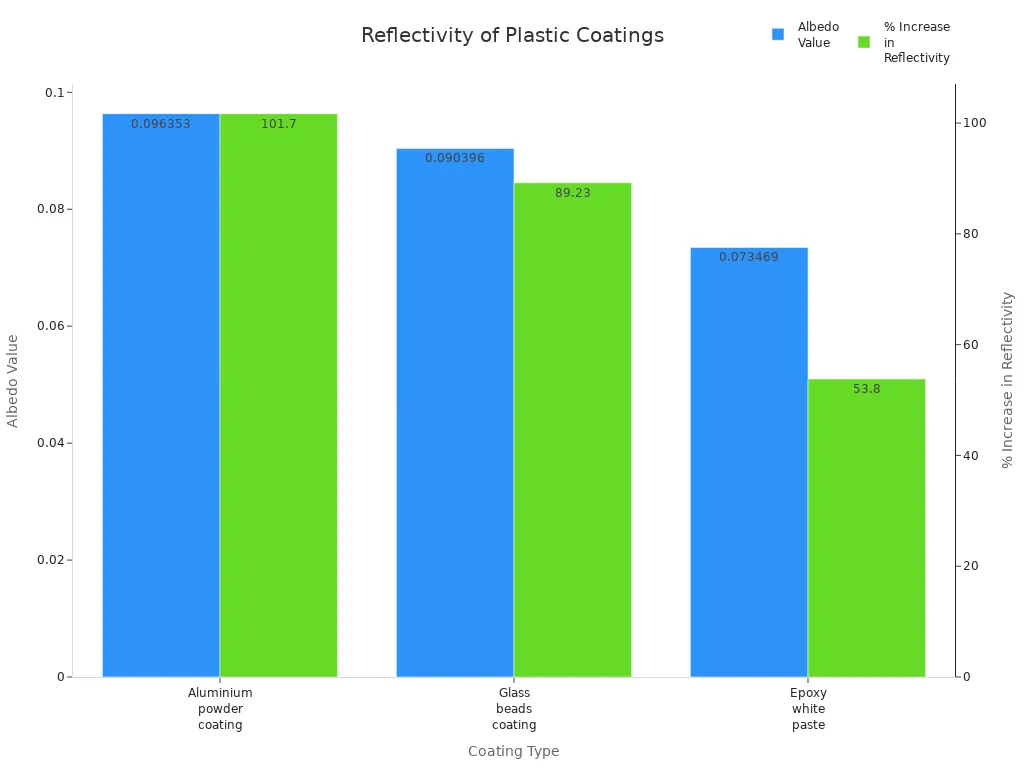

Revestimento plástico A pasta de alumínio faz com que os revestimentos plásticos reflitam muita luz. Isso significa que a superfície parece mais brilhante e mais fresca. A tabela abaixo mostra quanto mais luz os revestimentos de alumínio refletem do que outros:

| Tipo de revestimento | Valor do albedo | Aumento da refletividade % em comparação com a referência |

|---|---|---|

| Revestimento em pó de alumínio | 0.096353 | 101.7% |

| Revestimento com esferas de vidro | 0.090396 | 89.23% |

| Pasta branca epóxi | 0.073469 | 53.8% |

| Referência (sem revestimento) | Não se aplica | 0% |

Os revestimentos em pó de alumínio fazem com que os plásticos reflitam mais do que o dobro da luz. Essa alta refletividade também ajuda a bloquear os raios UV. O revestimento reflete a luz solar. Isso mantém o plástico protegido dos danos causados pelo sol. É uma boa opção para objetos e embalagens ao ar livre que precisam durar sob luz intensa.

Versatilidade e personalização

A pasta de alumínio com revestimento plástico funciona em muitos campos, pois pode ser alterada para se adequar a diferentes trabalhos. Os fabricantes podem alterar o tamanho das escamas de alumínio e a mistura da pasta. Isso permite que eles criem diversos aspectos e níveis de proteção.

- A pasta protege contra o ar, a água e a luz solar. Isso mantém os produtos seguros e frescos.

- Dá um aspecto metálico que faz com que as coisas pareçam mais valiosas.

- O revestimento ajuda a manter as coisas quentes ou frias. Isso é bom para embalagens de alimentos e medicamentos.

- A pasta é leve, resistente e não enferruja nem queima facilmente. Isso a torna ideal para carros, aparelhos eletrônicos e muito mais.

- As empresas podem escolher o tamanho e a mistura certos dos flocos para obter a aparência e a resistência desejadas.

- Embora custe mais do que alguns outros aditivos, suas diversas aplicações fazem dele uma compra inteligente para produtos de qualidade.

A pasta de alumínio é feita por moagem de alumínio em pequenas lascas. Esses flocos são misturados com outros materiais para ajudar a aderir e durar mais tempo. O processo pode ser alterado para tornar o revestimento mais brilhante, mais liso ou com melhor condução de eletricidade. Essa flexibilidade ajuda as empresas a criar novos produtos e melhorar os antigos.

Observação: A possibilidade de alterar a pasta significa que ela funciona em muitos setores, como automóveis, embalagens e eletrônicos.

Desvantagens da pasta de alumínio em plásticos

Fatores de custo

A pasta de alumínio com revestimento plástico custa mais do que a maioria dos aditivos. O O preço do pó e dos lingotes de alumínio varia muito.. Essas mudanças ocorrem devido a alterações nas regras de mineração, energia e comércio. Quando as matérias-primas ficam mais caras, a produção da pasta fica mais cara. Isso dificulta que as empresas mantenham os preços estáveis. A variação dos custos pode reduzir os lucros dos fabricantes. Eles podem precisar alterar os preços ou retardar o lançamento de novos produtos. Os compradores podem observar oscilações no preço dos plásticos revestidos.

Observação: As empresas precisam observar o mercado e se planejar com antecedência para as mudanças de preço.

Processamento e compatibilidade

Os fabricantes enfrentam problemas ao misturar pasta de alumínio com revestimentos plásticos. Se misturarem os ingredientes na ordem errada, podem formar-se grumos. Isso faz com que a superfície fique com um aspecto irregular. Uma mistura vigorosa pode partir as escamas de alumínio. As escamas partidas não brilham tanto. Se a pasta secar, pode causar mais problemas. Os trabalhadores devem manter a pasta coberta. Os pigmentos de alumínio não se misturam bem com sistemas à base de água. Estabilizadores ou revestimentos especiais ajudam a impedir a corrosão e a manter a pasta segura.

- Boas ferramentas de mistura e etapas cuidadosas protegem os pigmentos.

- Os testes laboratoriais ajudam a encontrar a melhor maneira de misturar cada revestimento.

- A direção dos flocos é importante. Uma direção inadequada torna o acabamento opaco.

- O uso do solvente errado pode danificar os pigmentos e reduzir a qualidade.

Pasta de alumínio revestida com resina corrige alguns problemas de mistura. A resina protege as partículas contra a ferrugem e ajuda-as a aderir aos plásticos. Isso faz com que os revestimentos durem mais e adiram melhor. Combinar a pasta com a resina plástica certa é importante para obter acabamentos resistentes.

Riscos ambientais e de segurança

Manipular pasta de alumínio pode ser perigoso para as pessoas e para a natureza. Poeira fina e líquidos inflamáveis podem causar incêndios ou explosões. Os trabalhadores precisam de máscaras contra poeira e luvas para se manterem seguros. A pasta deve ser armazenada em recipientes selados e seguros, longe da água e do fogo. Se os resíduos não forem manuseados corretamente, podem prejudicar a água, o solo e o ar. A reciclagem e o descarte seguro ajudam a reduzir esses perigos.

- O risco de incêndio aumenta se a pasta de alumínio se misturar com outros materiais inflamáveis.

- A água pode fazer com que a pasta se aglomere e enferruje, por isso mantenha-a seca.

- Ácidos ou bases fortes podem causar reações químicas indesejáveis.

- Controle da poluição significa reciclagem, uso de energia limpa e tratamento de água suja.

⚠️ O manuseio, armazenamento e descarte seguros protegem os trabalhadores e a natureza.

Impacto mecânico

A pasta de alumínio altera o funcionamento dos revestimentos plásticos. As escamas formam uma proteção que impede arranhões e danos. Isso ajuda o revestimento a durar mais tempo e manter uma boa aparência. A pasta também faz com que os revestimentos se curvem e adiram melhor. Isso impede rachaduras e descascamentos. Mesmo as escamas espalhadas aumentam a resistência e ajudam os revestimentos a durar mais tempo.

| Propriedade mecânica | Efeito da pasta de alumínio |

|---|---|

| Resistência à abrasão | As escamas de alumínio formam uma camada protetora que impede danos e desgaste. |

| Flexibilidade e aderência | A pasta ajuda os revestimentos a dobrar e aderir, impedindo rachaduras e descascamentos. |

| Estabilidade do revestimento | Até mesmo os flocos ajudam os revestimentos a permanecerem resistentes e com boa aparência. |

Mas ainda existem alguns problemas. Os tipos de folhas podem não aderir bem ao plástico. Isso pode fazer com que as lascas caiam ou diminuir a resistência a arranhões. Os sistemas à base de água precisam de cuidados especiais para manter a pasta segura e evitar reações adversas. Os fabricantes devem testar e alterar suas misturas para obter os melhores resultados.

Casos práticos de uso

Quando usar pasta de alumínio

A pasta de alumínio com revestimento plástico é ideal para obter um acabamento brilhante ou perolado.. Muitas empresas utilizam-no para ajudar os produtos a destacarem-se. Os fabricantes de automóveis utilizam-no para dar brilho às peças dos carros. As empresas de embalagens utilizam-no para dar um aspeto elegante às caixas e garrafas. Os produtos eletrónicos e outros bens utilizam-no para obter um estilo metálico e moderno.

Você escolhe os tipos com folhas ou sem folhas com base no que deseja. A pasta de alumínio folheado proporciona um brilho intenso e espelhado.. É ideal para acabamentos de automóveis, decorações e tintas brilhantes. A pasta de alumínio não folheada proporciona um aspecto mais suave e acetinado. Funciona melhor em revestimentos resistentes, como cadeiras de exterior ou peças de máquinas.

| Critérios | Pasta de alumínio para folhear | Pasta de alumínio sem folhas |

|---|---|---|

| Aparência | Alto brilho, espelhado | Metálico acetinado ou fosco |

| Durabilidade | Menos durável | Mais durável, resistente à abrasão |

| Melhor uso | Decoração, acabamentos automotivos, tintas de impressão | Revestimentos industriais, para embalagens e multicamadas |

Dica: A pasta de alumínio à base de água é boa para embalagens ecológicas e produtos que causam menos poluição.

Quando evitar

Às vezes, a pasta de alumínio com revestimento plástico não é a melhor escolha. Se algo for muito utilizado, os tipos folheados podem não durar muito tempo. Eles podem perder lascas e não aderir bem a outras camadas. Se um produto precisar de muitas camadas ou não puder ser riscado, use tipos não folheados ou dispense a pasta de alumínio.

Não utilize pasta de alumínio se o revestimento tiver de se dobrar ou esticar muito. As escamas podem partir-se ou fazer com que o revestimento rache. Se uma empresa quiser poupar dinheiro, a pasta de alumínio pode ser demasiado cara. É mais cara do que outros aditivos e requer uma utilização cuidadosa.

- Não utilize tipos de folhas para peças que são tocadas ou movidas com frequência.

- Evite usar pasta de alumínio se o revestimento precisar ser dobrado ou esticado.

- Evite-o em sistemas à base de água, a menos que a pasta seja feita para isso.

Observação: sempre teste o revestimento antes de usá-lo em toda a superfície. Isso ajuda a evitar problemas com a durabilidade ou a aparência.

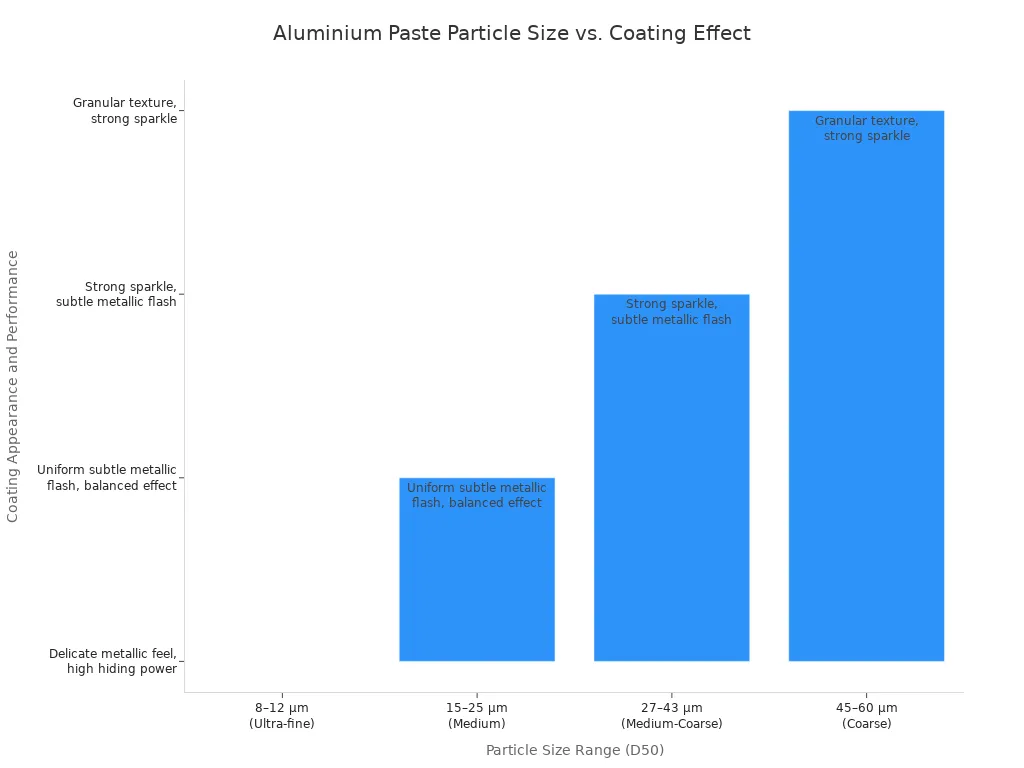

A pasta de alumínio com revestimento plástico ajuda a proteger os plásticos e confere-lhes um aspecto metálico. Também permite às empresas escolherem diferentes designs. As empresas precisam de pensar na aparência, na durabilidade e no custo. Devem escolher o tamanho de partícula adequado às suas necessidades.

| Faixa de tamanho das partículas (D50) | Efeito na aparência e no desempenho do revestimento | Aplicações típicas |

|---|---|---|

| 8–12 µm (ultrafino) | Toque metálico delicado, alto poder de cobertura | Interiores automotivos, eletrônicos |

| 15–25 µm (Médio) | Flash metálico uniforme, desempenho equilibrado | Tintas OEM, revestimentos para bobinas |

| 27–43 µm (Médio-Grosso) | Brilho intenso, acabamentos decorativos | Exteriores arquitetônicos |

| 45–60 µm (grosso) | Textura granulada, brilho intenso | Móveis, brinquedos |

As pessoas devem tomar medidas de segurança ao trabalhar com a pasta:

- Coloque luvas e máscara.

- Use óculos de proteção para proteger os olhos.

- Mantenha a pasta longe do calor.

- Escolha tipos à base de água para ajudar o meio ambiente.

Escolher a pasta certa e garantir a segurança ajuda as empresas a fazer um bom trabalho.

Perguntas frequentes

Qual é a diferença entre pasta de alumínio folheada e não folheada?

Pasta de alumínio folheada torna as coisas muito brilhantes, como um espelho. A pasta não folheada dá um aspecto mais suave e menos brilhante. Os tipos folheados permanecem na superfície do revestimento. Os tipos não folheados misturam-se com o revestimento. Cada tipo é mais adequado para diferentes trabalhos.

A pasta de alumínio é segura para o meio ambiente?

A pasta de alumínio pode prejudicar a natureza se não for utilizada corretamente. As pastas à base de água são mais seguras e causam menos poluição. As empresas devem reciclar os resíduos e descartá-los de forma segura para ajudar o planeta.

Os revestimentos de pasta de alumínio podem ser reciclados?

A maioria dos revestimentos com pasta de alumínio pode ser reciclada. As escamas de alumínio não impedem a reciclagem. Alguns revestimentos podem necessitar de medidas especiais antes da reciclagem. Verifique sempre as regras em vigor na sua região.

A pasta de alumínio afeta a resistência dos revestimentos plásticos?

A pasta de alumínio pode tornar os revestimentos mais resistentes. As escamas ajudam a evitar arranhões e danos. Alguns tipos podem tornar os revestimentos menos flexíveis, por isso é necessário testar cada produto.

Como os trabalhadores devem manusear a pasta de alumínio com segurança?

Os trabalhadores devem usar luvas., máscaras e óculos de proteção. Devem manter a pasta longe do calor e da água. Armazená-la em segurança e em local arejado ajuda a evitar acidentes.