The biggest difference between leafing and non leafing aluminium paste is how the flakes are arranged in a coating. Leafing and non leafing aluminium paste serve different purposes: leafing aluminium paste creates a shiny, mirror-like layer on the surface, while non leafing aluminium paste disperses evenly throughout the entire coating. This makes non leafing aluminium paste better for strength and protection. Many industries use leafing and non leafing aluminium paste for specific applications. For example, car manufacturers and factories are increasingly choosing non leafing aluminium paste for improved appearance and durability. If you want a bright, metallic finish in paint or ink, leafing aluminium paste is the best choice. On the other hand, non leafing aluminium paste is preferred for its ability to prevent rust and resist chemicals.

- The global market for non leafing aluminium paste was valued at about USD 1.2 billion in 2023.

- Experts predict it will reach around USD 2.3 billion by 2032, growing at a rate of 7.1% per year.

Choosing between leafing and non leafing aluminium paste ensures you achieve the best results for your project.

Principais conclusões

- Leafing aluminum paste gives a bright, shiny look. It is great for decorations. Non-leafing aluminum paste spreads out evenly. It protects well from rust and chemicals. Pick leafing paste if you want things to look nice. Use non-leafing paste if you need it to last in tough places. Think about what your project needs. This helps you pick the best aluminum paste.

Leafing and Non Leafing Aluminium Paste Overview

What is Leafing Aluminum Paste

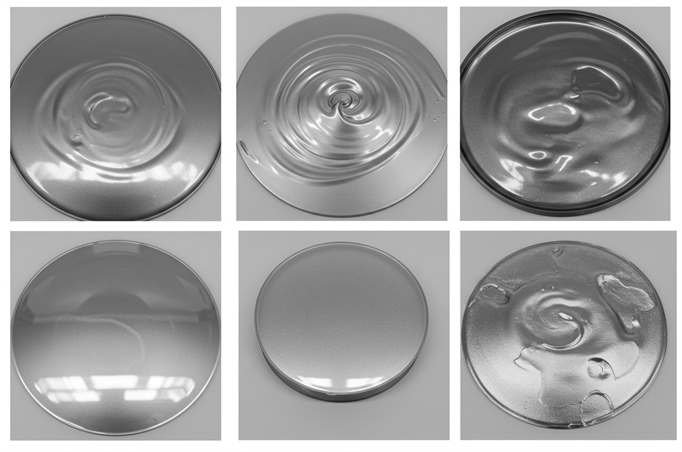

Leafing aluminum paste is a kind of metallic pigment. When you use this paste in paint, the flakes float to the top. They line up on the surface. This makes the paint look shiny and like a mirror. It reflects light and looks like chrome. You can see this in car paint and fancy coatings. Some protective finishes use it too.

Making leafing aluminum paste takes many steps:

- First, people grind aluminum powder to the right size. Then they mix it with binders and dispersants.

- High-shear mixers blend the powder with binders. This coats each flake well.

- Surface treatments keep the paste stable. They stop the aluminum from rusting.

- Quality control checks the size and spread of the flakes. They also check how well the flakes float.

- The paste goes into airtight containers. This keeps it fresh.

- When you use the paste, the flakes move to the top. They make a bright, metallic layer.

Leafing aluminum paste is good for strong visual effects. It also gives some protection from the environment. The floating flakes make a barrier. This helps block water and chemicals.

What is Non Leafing Aluminum Paste

Non leafing aluminum paste works in a different way. When you add this paste to paint, the flakes spread out evenly. They do not float to the top. They stay mixed inside the paint. This gives a smooth finish that is not very shiny.

Non leafing aluminum paste is used when you need strong protection. It also sticks well to other pigments and resins. This makes the coating tough and hard to wear down. It also resists chemicals and weather. You can find non leafing aluminum paste in car paint, machines, and electronics.

Key Differences and Why They Matter

You can see the main differences in the table below:

| Recurso | Pasta de alumínio para folhear | Pasta de alumínio sem folhas |

|---|---|---|

| Descrição | Flakes float on the surface and make a shiny layer. | Flakes mix evenly through the paint. |

| Características | Very shiny, looks like chrome, strong surface barrier. | Even spread, sticks well, works with many pigments. |

| Formulários | Used for shiny looks and surface protection in cars and furniture. | Used for strong coatings in cars, furniture, and electronics. |

Dica: If you want a bright, metallic look, pick leafing aluminum paste. If you need a tough and long-lasting coating, non leafing aluminum paste is better.

When you choose between leafing and non leafing aluminium paste, you decide how your coating will look and work. Leafing types give shine and surface protection. Non leafing types give strength and even coverage. Companies like Five Star Aluminium Paste sell both kinds. You can pick the right one for your project.

Technical Properties Comparison

Metallic Brightness and Finish

You want your coating to look bright and shiny. Leafing aluminum paste gives a strong metallic shine. The flakes float up and reflect light. This makes the finish look like a mirror. It works well for car paint, signs, and decorations. Non-leafing aluminum paste gives a softer metallic look. The flakes mix evenly in the paint. The shine is not as strong but looks even. You see the same reflection from every angle.

- Leafing aluminum paste makes the coating sparkle under bright light.

- Non-leafing aluminum paste gives a soft metallic effect with even shine.

If you want a bold, shiny finish, leafing aluminum paste is best. For a smooth and even metallic look, non-leafing aluminum paste works better.

Barrier Effect and Protection

You want your coating to protect against water and chemicals. Non-leafing aluminum paste gives stronger protection. The flakes spread out and make a thick shield. This shield stops rain, scratches, and heat. Non-leafing aluminum paste keeps working well over time, even in tough places.

Leafing aluminum paste makes a surface barrier, but it can get weaker if flakes fall off. Over time, the protection may not last. Non-leafing aluminum paste stays strong because the flakes do not float away. You get good protection for machines and vehicles.

Tip: For long-lasting protection, pick non-leafing aluminum paste. It stands up to harsh weather and keeps your coating strong.

Abrasion Resistance and Durability

You need your coating to last and not get damaged. Non-leafing aluminum paste works better in hard places. It stops cracks and fading. The flakes stick well with other pigments and resins. This helps the coating stay strong.

Leafing aluminum paste gives good water resistance at first. Over time, the shiny layer may peel or not stick well. You might see problems after using it for a long time.

Here is a table that shows how both types compare:

| Type of Aluminum Paste | Durability in Tough Environments | Water Resistance | Long-term Performance |

|---|---|---|---|

| Non-leafing | Lasts longer, stops cracks and fading | Moderado | Better durability over time |

| Leafing | Good water resistance at first, but gets weaker later | Alta | May not stick well after long use |

If you want a coating that lasts, non-leafing aluminum paste is better. Many companies, like Five Star Aluminium Paste, suggest it for factories and machines.

Compatibility with Coatings

You want your aluminum paste to work with different paints. Leafing aluminum paste floats to the top, which can cause problems. The shiny layer may stop new paint from sticking. You might see peeling or uneven spots. Leafing aluminum paste does not stop rust well, so water and air can get in.

Non-leafing aluminum paste mixes evenly and helps the paint dry right. It works with water-based and solvent-based coatings. You get better sticking and a stable finish. Non-leafing aluminum paste helps your coating stay strong.

| Compatibility Issue | Descrição |

|---|---|

| Flotation of aluminum paste | Leafing aluminum paste floats to the top, causing uneven coverage. |

| Poor rust prevention | The paste does not stop rust, so water and air can get in. |

| Difficulty in adhesion | The shiny layer makes it hard for new paint to stick, causing peeling. |

| Weak bonding in multi-layer coatings | The flakes can make weak bonds, making it hard to add more layers. |

| Uneven spots when painting | Coatings with leafing aluminum paste may not stick well, causing uneven spots. |

Non-leafing aluminum paste is better for industrial coatings. It helps paint stick well and works with many types of paint. Five Star Aluminium Paste sells both kinds, so you can pick what you need.

Performance in Industrial Applications

Resistência à corrosão

You want coatings to last in hard places. Leafing aluminum paste makes a shiny layer on top. This layer keeps water out and helps in bad weather. Some leafing pastes have silicone resin. This helps them handle heat better. You see these used on outdoor signs and metal roofs. Non-leafing aluminum paste works in another way. It spreads flakes all through the coating. This gives strong protection from rust and chemicals. Non-leafing paste sticks well and does not peel off. You can use it on machines, vehicles, and factory tools. Five Star Aluminium Paste sells both types, so you can pick what you need.

Appearance and Gloss

You can see each paste looks different. Leafing aluminum paste gives a shiny, mirror look. It bounces light and makes things look glossy. You see this on car parts and decorations. Non-leafing aluminum paste gives a softer, matte look. The flakes mix well, so the shine is less but even. You get a smooth finish that is good for protection.

Here is a table that shows how each paste looks on cars:

| Type of Paste | Appearance Characteristics |

|---|---|

| Non-leafing Paste | Subdued, metallic matte finish |

| Leafing Paste | Shiny, reflective, and glossy surface |

- Non-leafing aluminum paste spreads evenly in the coating.

- You get a smooth metallic look.

- It sticks better with binders.

- It works well with clear coats.

Adequação da aplicação

You need to pick the right paste for your job. Leafing aluminum pigments make a chrome-like shine. Use them when you want a bright, shiny surface. These need a clear coat on top to stop damage. Leafing paste is best for decorations and things that must stand out. Non-leafing aluminum pigments give a sparkle and fight chemicals well. Makers use oleic acid to keep non-leafing paste stable. You see it in powder coatings, machines, and electronics. Non-leafing paste works in hot places and tough jobs. Five Star Aluminium Paste can help you choose the best one, whether you want shine or strength.

Typical Uses and Industry Examples

Leafing Paste Applications

Leafing aluminum paste is used in many industries. It is picked when a shiny, metallic look is needed. Car makers use it to make cars look bright and new. This paste helps cars look cool and modern. Factories use it to coat machines and tools. These coatings help stop rust and damage. Printers use leafing aluminum paste in inks. This makes labels and packages shine on store shelves. Shiny packaging helps products get noticed.

Here is a table that shows where leafing aluminum paste is used:

| Industrial Use | Descrição |

|---|---|

| Revestimentos automotivos | Used for shiny finishes, making cars look better and lighter. |

| Revestimentos industriais | Protects machines from rust and helps them last longer. |

| Tintas de impressão | Makes prints bright and shiny, which is good for packaging. |

Leafing aluminum paste is popular in cars, buildings, and packaging. These areas want coatings that look nice and last a long time. Paints with leafing aluminum paste give a metallic shine that stands out.

| Setor | Reason for Demand |

|---|---|

| Automotivo | Makes cars look good and helps stop rust. |

| Construção | Used for shiny building paints that last. |

| Embalagem | Makes boxes and labels look like metal. |

| Tintas e revestimentos | Gives a metallic shine in many kinds of paint. |

| Other Industries | Used in inks, plastics, and special coatings people like. |

Tip: If you want your coating to look like chrome or silver, use leafing aluminum paste.

Non Leafing Paste Applications

Non leafing aluminum paste gives strong protection and a smooth look. It is used where things need to last a long time. Factories use it on machines and tools. It helps stop rust and keeps things safe from chemicals. Car makers use it in base coats to help cars last longer. Electronics companies use it to protect parts from heat and wear.

You can use non leafing aluminum paste in powder coatings and ship paints. It is also good for big machines. It works with many paints and resins. This makes it great for tough jobs. Five Star Aluminium Paste sells both types, so you can choose what you need.

- Use non leafing aluminum paste for:

- Factory machines and tools

- Ship and boat paints

- Coatings for electronics

- Powder coatings for home appliances

Note: If you need a coating that lasts and protects, non leafing aluminum paste is the best choice.

Choosing the Right Aluminum Paste

Key Factors to Consider

When you pick aluminum paste, you should think about a few things. Each thing changes how your coating looks and works. The table below can help you choose:

| Key Factor | Recommendation |

|---|---|

| Proteção contra corrosão | Use leafing aluminum paste for tanks, marine coatings, and machines. Its top layer keeps out water and chemicals. |

| Aesthetic Flexibility | Pick non-leafing paste for car paint, plastic parts, and makeup boxes. It spreads evenly and gives more color choices. |

| Regulatory Compliance | Try water-based non-leafing pastes if you need to follow eco rules like REACH or RoHS. These are safer for the earth and work well. |

How well the paste works is very important. Aluminum paste helps your coating last longer and stops damage. How it looks also matters. If you want a shiny, metallic look, leafing paste is best. For a smooth and even finish, non-leafing paste is better. You also need to check if the paste works with your paint or resin. If they work well together, your coating will stick and last longer.

Many people now want good aluminum paste. Lots of industries use it for strong and shiny finishes. Five Star Aluminium Paste sells both types, so you can get what you need.

Tip: Always pick the paste that fits your project. Think about how it will look, how long it will last, and if it follows safety rules.

Common Selection Mistakes

You can stop problems if you watch out for these mistakes:

- Picking the wrong solvent can make your coating turn out bad.

- Not testing new solvents on a small scale can cause mixing problems or bubbles.

- Using chlorinated solvents can make aluminum flakes dark and unsafe.

- Letting water touch aluminum paste can make hydrogen gas. This is dangerous and makes the shine go away.

You should also care about safety and the environment. Use safe solvents, keep air moving in your workspace, and wear safety gear. Always follow safety rules.

Here are some tips from experts to help you choose well:

- Make sure your supplier is a real factory, not just a trading company. Look for ISO 9001 and ask for technical data sheets.

- Be clear about what you need, like the type of paste, carrier, and flake size.

- Talk to sales reps who know a lot and can answer your questions fast.

If you want good results, brands like Five Star Aluminium Paste can help you pick the right paste.

You now know the key differences between leafing and non-leafing aluminum paste. Leafing paste gives you a shiny, mirror-like finish. Non-leafing paste offers strong protection and even coverage. If you want a bright look, choose leafing paste. For tough jobs, pick non-leafing paste. Five Star Aluminium Paste helps you find the best option for your project.

Tip: Always match the paste to your needs for the best results.

Perguntas frequentes

Qual é a principal diferença entre a pasta de alumínio folheada e não folheada?

Leafing aluminum paste makes a shiny layer on top. Non-leafing aluminum paste spreads out inside the coating. Pick one based on how you want it to look and protect.

Can I use both types of aluminum paste in the same project?

You can use both types, but test them first. Mixing them might change how it looks or works. Five Star Aluminium Paste says to ask experts before you mix them.

Which aluminum paste works best for outdoor protection?

Non-leafing aluminum paste is better for outdoor use. It stops rust and keeps out chemicals. You get a strong finish for cars, machines, or buildings.

How do I store aluminum paste safely?

Keep aluminum paste in closed containers. Store it away from water and heat. Always follow safety rules from Five Star Aluminium Paste to stay safe.

Where can I buy high-quality aluminum paste?

You can get good aluminum paste from Five Star Aluminium Paste. They sell both leafing and non-leafing types for many uses.