CONECTAR

Entraremos em contato com você dentro de 24 horas.

Para consultas urgentes, entre em contato conosco pelo número do whatsapp: +86-18001668319

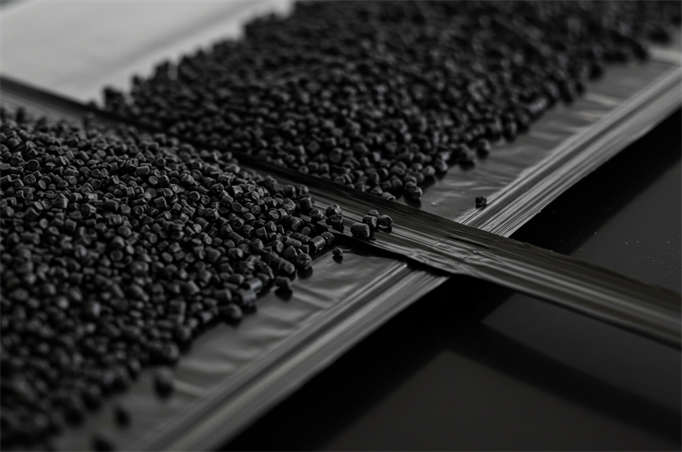

PBT black masterbatch consists of high-concentration carbon black, PBT carrier resin, and advanced dispersants. Produced via twin-screw extrusion, it ensures uniform pigment dispersion, providing high color depth, heat resistance , and mechanical stability. Ideal for PBT engineering plastics in electronics (connectors, switches), automotive components, and industrial parts, meeting requirements for UV resistance and flame retardancy. Eco-friendly options comply with RoHS.

PBT black masterbatch consists of high-concentration carbon black, PBT carrier resin, and advanced dispersants. Produced via twin-screw extrusion, it ensures uniform pigment dispersion, providing high color depth, heat resistance , and mechanical stability. Ideal for PBT engineering plastics in electronics (connectors, switches), automotive components, and industrial parts, meeting requirements for UV resistance and flame retardancy. Eco-friendly options comply with RoHS.

PP black masterbatch (fiber grade) combines highly dispersible carbon black, high-flow PP homopolymer carrier, and specialized dispersants. Optimized for polypropylene fiber spinning, it undergoes high-shear processing to eliminate gel particles and ensure low VOC emissions, compatible with high-speed spinning. Provides uniform coloration, high tensile strength, and light resistance. Used in apparel, non-woven fabrics, and industrial fibers.

At Five New Materials, we proudly present our high-performance PBT Black Masterbatch, specifically engineered for Polybutylene Terephthalate (PBT) materials. Our advanced formulation combines carbon black, carrier resin, and functional additives to deliver superior coloring performance across electronics, automotive components, and engineering plastics applications.

We use PBT resin as the primary carrier in our masterbatch, ensuring perfect compatibility with base materials and preventing material stratification or performance degradation.

Our standard formulations contain 30%-45% carbon black, while our high-concentration products reach 60%-70%, providing excellent blackness and coverage power.

We incorporate:

We employ a sophisticated production process:

We strictly control:

Our masterbatch delivers high blackness with smooth surface finish without compromising PBT’s toughness, flame retardancy, or insulation properties—making it ideal for precision electronic components.

We proudly meet European SGS, RoHS, and FDA certifications, with zero heavy metals or harmful substance emissions.

With low addition rates (2%-4%), our masterbatch reduces raw material costs and production pollution while minimizing machine cleaning and color change losses.

We serve manufacturers of sockets, connectors, and motor housings with solutions meeting insulation and antistatic requirements.

Our masterbatch excels in high-temperature applications such as lamp brackets and sensor housings.

We create specialized formulations for glass fiber composites, flame-retardant materials, PBT alloys, and reinforced materials.

We recommend choosing specialized masterbatch with PBT carriers rather than universal masterbatch that may reduce physical properties.

We help you select antistatic, flame-retardant, or high-gloss grade products based on your application scenario. For example, our antistatic masterbatch requires 15%-25% addition rates.

Five New Materials maintains comprehensive environmental certifications (SGS), advanced production equipment (including Coperion twin-screw extruders), and superior technical support capabilities.

Contact Five New Materials today to discover how our PBT Black Masterbatch can enhance your product performance while meeting stringent quality and environmental standards.

At Five New Materials, we specialize in premium PP Polypropylene Spinning Grade Black Masterbatch specifically engineered for polypropylene fiber spinning applications. Our advanced formulations combine superior dispersibility with excellent processability to meet the demanding requirements of fiber production across various industries.

We design our masterbatch specifically for PP fiber spinning, making it perfect for 100D~900D long filament, fine denier, and ultra-fine denier fiber production. Our superior dispersibility prevents nozzle clogging and fiber breakage during the spinning process.

The recommended addition range is 0.8%~5% (adjustable based on equipment and process requirements) to ensure smooth processing performance.

We offer standard colors for the wig industry (such as 1# and 1B# colors) and support customized color matching to meet specific denier, light fastness, and heat resistance requirements.

Our masterbatch works excellently with:

We provide high blackness and realistic effects for wig fiber production, meeting industry standards.

Our versatile masterbatch serves multiple industries:

We implement a high-volume, low-margin strategy with direct raw material sourcing to maintain competitive pricing.

Our 7 production lines support rapid delivery with standard products available from stock and custom products delivered within 3-5 days.

We source raw materials exclusively from qualified major suppliers, maintain a comprehensive quality monitoring system, and utilize advanced testing equipment. We guarantee product replacement or refund for quality issues.

We offer free 1kg samples (shipping collect) to support testing before bulk purchases.

For customers in the Pearl River Delta region, we resolve after-sales issues with on-site service within 24 hours.

We provide 13% VAT special invoices with transparent tax-inclusive pricing.

Due to potential color variations caused by lighting conditions or equipment differences, we recommend sampling first to confirm color and performance.

Select the appropriate grade based on your fiber specifications (such as denier and temperature resistance requirements) or contact our team for customized solutions.

Many of our products comply with ROHS environmental requirements, making them suitable for export or high-standard applications.

Contact Five New Materials today to discover how our PP Polypropylene Spinning Grade Black Masterbatch can enhance your fiber production quality while improving processing efficiency.

At Five New Materials, we continuously innovate our production processes to deliver superior PBT Black Masterbatch products. Our latest technological advancements have revolutionized how we manufacture these specialized coloring agents, resulting in enhanced performance, improved sustainability, and greater cost-effectiveness.

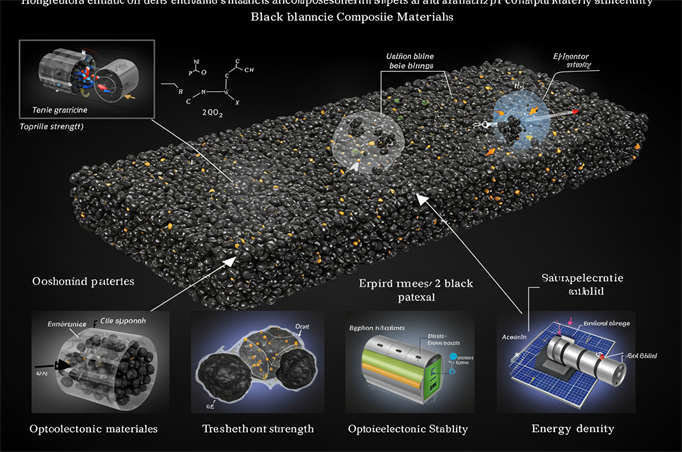

We utilize imported high-pigment carbon black with our proprietary nano-level dispersion technology that controls particle size between 15-30nm. By integrating silane coupling agent coating modification, we significantly enhance compatibility between carbon black and PBT carriers while reducing agglomeration phenomena.

We select food-grade PBT resin as the carrier, complemented by halogen-free flame retardants and environmentally friendly dispersants (such as polyethylene wax). Our products pass European RoHS and FDA certifications, making them ideal for demanding applications in automotive interiors and electronic devices.

We directly incorporate antistatic agents (15%-25% addition), light stabilizers, or flame retardants into our masterbatch, achieving “coloration + functionality” integrated production that simplifies downstream processing steps.

We pioneered China’s first production of PBT black masterbatch using rich aromatic oil as raw material. Through high-temperature pyrolysis and impurity removal technology, we achieve efficient utilization of raw materials while reducing energy consumption by over 30%.

We’ve installed waste heat recovery devices in our twin-screw extrusion process, converting waste heat into steam for our production lines and reducing dependence on external energy sources.

We implement a continuous production model combining intensive mixer pre-dispersion with twin-screw extrusion pelletizing. With automated feeding, online monitoring, and intelligent temperature control systems, we ensure carbon black dispersion exceeds 98%.

Through process modifications, we’ve achieved simultaneous production of black masterbatch and carbon black, extending our industrial chain while reducing overall costs.

The exhaust gas generated during production undergoes purification treatment before replacing natural gas for heating, reducing carbon emissions by 40%.

We’ve developed carrier-free or low-carrier content (<10%) products using supercritical CO₂-assisted dispersion processes, avoiding physical property losses caused by traditional carrier resins.

In the pigment pretreatment stage, we employ water-based dispersion systems to replace traditional organic solvents, significantly reducing VOCs emissions.

We’re researching PBT resins made from bio-based butanediol to enhance the biodegradability of our masterbatch products.

By using AI to simulate carbon black dispersion processes, we make real-time adjustments to screw speed and temperature parameters for optimal results.

We’re developing formulations that include nucleating agents or glass fibers in the masterbatch to simultaneously improve crystallinity and mechanical strength of PBT materials.

The application of these new technologies has significantly enhanced the quality stability and production efficiency of our PBT Black Masterbatch. According to industry calculations, companies adopting the rich aromatic oil process can reduce comprehensive costs by 18-25%.

Contact Five New Materials today to learn how our advanced production technologies can deliver superior PBT Black Masterbatch for your specific applications.

At Five New Materials, we understand that different spinning processes demand specific black masterbatch formulations. Our specialized PP Black Masterbatch products are engineered to meet the unique requirements of various polypropylene fiber production methods.

The one-step spinning process directly blends masterbatch with PP raw materials for melt spinning, requiring exceptional dispersibility to prevent nozzle clogging or fiber breakage. Our products achieve:

Processing temperatures typically range from 230~260°C, requiring masterbatch with heat resistance ≥240°C to ensure stability without decomposition or discoloration during production.

The two-step spinning process subjects the melt to two heating and stretching cycles, with temperatures reaching 280~300°C. Our specialized formulations feature:

We employ twin-screw pelletizing technology to:

Our masterbatch meets wig industry standard color codes (such as 1# and 1B#) with:

For 100D~300D ultra-fine denier fibers, we offer specialized formulations featuring:

Since nonwoven fabrics are often used in outdoor or daily-use products, our masterbatch includes:

We ensure:

For coarse filament (≥900D), our masterbatch provides:

Our specialized grades feature:

We ensure all products meet:

We support your production needs with:

Contact Five New Materials today to discover the ideal PP Black Masterbatch formulation for your specific spinning process requirements.

Sugerimos que você se comunique conosco antes de comprar, pois certamente consideraremos todos os aspectos e ofereceremos um plano de preços justo e razoável. Ao nos escolher, você obterá o melhor produto e o melhor valor pelo seu dinheiro.

Choosing the right size of product gives you the best value for money. Our White Masterbatch is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

Quanto maior a quantidade comprada, menor será o preço unitário. Os pedidos em grandes quantidades nos permitem dividir melhor nossos custos operacionais e de produção, por isso temos o prazer de oferecer preços com desconto para compras em grandes quantidades.

O prazo e o método de pagamento que você escolher também afetarão o preço. Por exemplo, o pagamento integral antecipado pode resultar em um preço mais favorável, pois reduz nosso custo de capital. Discuta a opção de pagamento mais adequada com nossa equipe de vendas.

O transporte e a logística também são fatores que afetam o custo total de propriedade. Diferentes modos de transporte e destinos incorrerão em diferentes custos de remessa. Taxas, seguros e outros custos também precisam ser levados em conta. Ao calcular esses fatores antes da compra, você pode estimar com mais precisão o custo total.

Na Five Star Material, entendemos que cada projeto é único, e nosso objetivo é fornecer as melhores soluções personalizadas para cada cliente.

Entraremos em contato com você dentro de 24 horas.

Para consultas urgentes, entre em contato conosco pelo número do whatsapp: +86-18001668319