CONECTAR

Entraremos em contato com você dentro de 24 horas.

Para consultas urgentes, entre em contato conosco pelo número do whatsapp: +86-13309617918

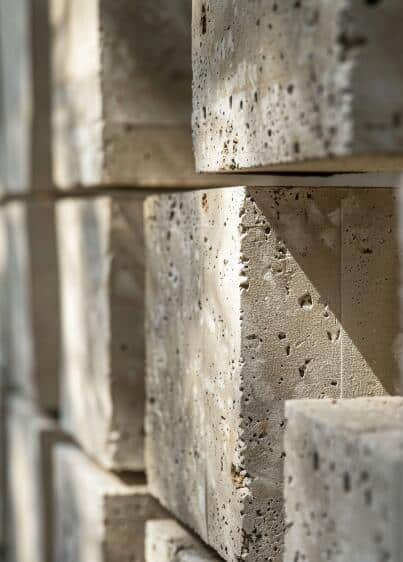

A função da pasta de alumínio no concreto leve é principalmente como agente espumante e seu desempenho afeta diretamente a qualidade e as propriedades do concreto.

A função da pasta de alumínio no concreto leve é principalmente como agente espumante e seu desempenho afeta diretamente a qualidade e as propriedades do concreto. A seguir, alguns parâmetros importantes que afetam o desempenho da pasta de alumínio:

1. Pureza: A pureza de uma pasta de alumínio geralmente é expressa em porcentagem. Uma pureza maior geralmente significa que há mais ingredientes ativos na pasta e que o efeito de formação de espuma pode ser melhor. Por exemplo, a pureza 65% da pasta de alumínio significa que ela pode conter outros ingredientes além do alumínio.

2, Teor de alumínio ativo: o teor de alumínio ativo refere-se à porcentagem de alumínio na pasta que pode participar da reação química e produzir gás. Um teor mais alto de alumínio reativo geralmente significa que mais gás pode ser produzido durante o processo de reação, formando assim mais espuma.

3, Tamanho da partícula: o tamanho da partícula (D50) significa que, sob determinadas condições, 50% das partículas são menores que esse tamanho em diâmetro. A pasta de alumínio com tamanho de partícula menor pode liberar gás mais rapidamente e de forma mais uniforme ao reagir com a água, o que ajuda a formar uma estrutura de espuma uniforme.

4, Conteúdo não volátil: o conteúdo não volátil refere-se à proporção de componentes não voláteis na pasta de alumínio após o aquecimento sob condições específicas. Esse parâmetro reflete a estabilidade da pasta de alumínio no processo de aquecimento; quanto maior o conteúdo não volátil, indicando que a pasta de alumínio no processo de aquecimento, menor a perda de componentes.

Esses parâmetros determinam o desempenho da pasta de alumínio em concreto leve, incluindo sua capacidade de formação de espuma, estabilidade e as propriedades físicas do concreto final.

1. Método de análise química: Separe o elemento alumínio da amostra dissolvendo a amostra de concreto e, em seguida, use reagentes químicos para a determinação quantitativa. Esse método tem alta precisão, mas exige condições laboratoriais e habilidades operacionais profissionais.

2、Métodos de análise espectral: incluindo espectrometria de absorção atômica (AAS), espectrometria de emissão de plasma indutivamente acoplado (ICP-OES) e espectrometria de fluorescência de raios X (XRF). Esses métodos podem medir diretamente o conteúdo do elemento alumínio na amostra, com características rápidas e precisas, mas precisam de instrumentação cara e técnicos profissionais para operar.

*Espectrometria de Absorção Atômica (AAS): análise quantitativa que utiliza a absorção de átomos de alumínio em comprimentos de onda específicos de luz.

*Espectrometria de Emissão de Plasma Acoplado Indutivamente (ICPES): análise quantitativa por meio da excitação de átomos de alumínio na amostra e da medição dos espectros característicos emitidos por eles.

* Espectrometria de fluorescência de raios X: usando a irradiação de raios X da amostra, medindo a intensidade da fluorescência emitida pelos átomos de alumínio após serem excitados para determinar o teor de alumínio.

3. Método de peneiramento: Para o concreto leve que contém uma grande quantidade de pó de alumínio, as partículas de pó de alumínio podem ser separadas do concreto por peneiramento e pesadas para calcular o teor de pó de alumínio. Esse método é simples e rápido, mas a precisão é relativamente baixa, apenas para casos específicos.

4, Método de observação por microscópio: o uso de observação por microscópio de amostras de concreto na forma de partículas e distribuição de pó de alumínio, combinado com a tecnologia de processamento de imagens para análise quantitativa. Esse método é aplicável à necessidade de entender a distribuição do pó de alumínio no concreto.

5 、 Organizações de testes profissionais: Se você não tiver condições de fazer a medição por conta própria, poderá enviar as amostras para organizações de testes profissionais para serem testadas. Essas instituições geralmente têm equipamentos avançados e técnicos profissionais, e podem fornecer resultados de teste precisos e confiáveis.

1. densidade e peso: com o aumento do teor de pó de alumínio, a quantidade de hidrogênio produzida pela pasta de alumínio no concreto aumenta, levando a um aumento no número de bolhas dentro do concreto, reduzindo assim a densidade e o peso do concreto.

2. resistência: a quantidade certa de pó de alumínio pode melhorar a resistência à compressão do concreto, pois as partículas de pó de alumínio podem preencher os minúsculos poros do concreto, reduzir a porosidade e melhorar a compactação. No entanto, quando o teor de pó de alumínio é muito alto, o excesso de bolhas pode fazer com que a estrutura interna do concreto se solte, mas reduz a resistência.

3, durabilidade: o pó de alumínio e outros componentes na reação do concreto podem formar novos materiais cimentícios, ajudando a aumentar a durabilidade do concreto. Entretanto, o excesso de pó de alumínio pode produzir reações químicas desfavoráveis, afetando a durabilidade.

4, Isolamento térmico: o aumento da estrutura de bolhas melhora o isolamento térmico do concreto; quanto maior for o teor de pó de alumínio, melhor será o efeito de isolamento térmico.

5. capacidade de construção: a quantidade certa de pó de alumínio pode melhorar a fluidez e a capacidade de trabalho do concreto e aumentar a eficiência da construção. Entretanto, o excesso de pó de alumínio pode fazer com que o concreto fique muito solto, o que não favorece a construção.

A quantidade de pasta de alumínio usada depende da densidade de volume do AAC. Ao usar pasta de alumínio da mesma qualidade, quanto maior for a densidade volumétrica do produto, menor será a quantidade de pasta de alumínio usada.

De fato, podemos calcular com precisão a quantidade de pasta de alumínio usada com base na densidade do volume do produto:

Com base na fórmula de reação da pasta de alumínio que substitui o hidrogênio na água em um ambiente alcalino:

2AL 3Ca(OH)2 6H2O-3Ca.AI2O3.6H2O 3H2↑

De acordo com as estatísticas, 2 gramas de alumínio metálico puro podem produzir 3 gramas de H2, mas, em condições padrão, o volume de 1 grama de gás é 22,41, e o peso atômico do alumínio é 27. Portanto, a produção de gás da pasta de alumínio é:

Vo=22.4X1.241/[3/2X27]g

De acordo com a fórmula acima, a produção de gás da pasta de alumínio sob várias condições pode ser calculada usando a equação do estado de vapor (V1/T1)=(V2/T2):

O volume de AAC pode ser simplificado em duas partes: uma é o volume aprovado do material de base e a outra é o volume de poros formado depois que a pasta de alumínio é gaseificada. De acordo com o volume dos poros, a quantidade de pasta de alumínio pode ser calculada:

M alumínio=V poro/(V2K)

No tipo: M alumínio - a quantidade de pasta de alumínio usada nos produtos da empresa (g/cúbico);

K - teor de alumínio ativo

O volume de poros é igual ao volume do produto, combinado com a quantidade de materiais e suas respectivas proporções para reduzir o volume de matérias-primas e água.) No entanto, durante o processo de produção, a produção de gás é afetada por muitos fatores, como mudanças de temperatura e consistência da pasta. De acordo com cálculos teóricos, a quantidade de pasta de alumínio é impossível e desnecessária. A fábrica seleciona com base na experiência social e faz ajustes a qualquer momento. De modo geral, ao usar pasta de alumínio, a pasta de alumínio é adicionada em uma proporção de 8/10.000 materiais secos para produzir 600 kg/cúbico de concreto aerado.

| Nome do produto | Conteúdo sólido (%) | Alumina ativa (%) | Densidade a granel | Tamanho médio da partícula (D₅₀) | Adequado para AAC |

|---|---|---|---|---|---|

| DEG-60 | 70% | ≥96 | 0.15 | 58-62 | <600 |

| DEG-40 | 70% | ≥94 | 0.15 | 36-42 | <500 |

| DEG-35 | 70% | ≥94 | 0.15 | 33-35 | <400 |

| DEG-25 | 70% | ≥94 | 0.15 | 25-27 | <400 |

| DEG-18 | 70% | ≥92 | 0.11 | 17-19 | <350 |

Sugerimos que você se comunique conosco antes de comprar, pois certamente consideraremos todos os aspectos e ofereceremos um plano de preços justo e razoável. Ao nos escolher, você obterá o melhor produto e o melhor valor pelo seu dinheiro.

Ao escolher o tamanho certo do produto, você obtém a melhor relação custo-benefício. Nossa pasta de alumínio para tijolos de concreto leve está disponível em uma ampla gama de tamanhos de partículas e purezas, com preços que variam de acordo com a especificação. Ao comunicar detalhadamente suas necessidades e escolher o tamanho certo, você pode obter o melhor custo-benefício.

Quanto maior a quantidade comprada, menor será o preço unitário. Os pedidos em grandes quantidades nos permitem dividir melhor nossos custos operacionais e de produção, por isso temos o prazer de oferecer preços com desconto para compras em grandes quantidades.

O prazo e o método de pagamento que você escolher também afetarão o preço. Por exemplo, o pagamento integral antecipado pode resultar em um preço mais favorável, pois reduz nosso custo de capital. Discuta a opção de pagamento mais adequada com nossa equipe de vendas.

O transporte e a logística também são fatores que afetam o custo total de propriedade. Diferentes modos de transporte e destinos incorrerão em diferentes custos de remessa. Taxas, seguros e outros custos também precisam ser levados em conta. Ao calcular esses fatores antes da compra, você pode estimar com mais precisão o custo total.

O processo de produção de pasta de alumínio aerada (slurry)/pó é fundamental para determinar a qualidade e o desempenho do produto final. Este capítulo detalhará o fluxo de produção, as principais tecnologias e os pontos de controle de cada etapa do processo de fabricação da pasta de alumínio aerada (slurry)/pó para ajudar os leitores a entender melhor a fabricação desse material essencial.

O fluxo de produção de pasta de alumínio aerada (slurry)/pó normalmente inclui as seguintes etapas principais:

Antes do início da produção, a seleção e a preparação das matérias-primas são cruciais. A principal As matérias-primas incluem pó de alumínio, aditivos (como DEG, dispersantes, etc.) e outros ingredientes. A seleção do pó de alumínio geralmente se baseia em seu tamanho de partícula, atividade e pureza. O pó de alumínio altamente ativo pode gerar mais gás hidrogênio ao reagir com a água, obtendo assim melhores efeitos de geração de gás. A seleção de aditivos precisa considerar sua função na pasta de alumínio aerada, como melhorar a fluidez e aumentar a reatividade.

O pó de alumínio preparado e os aditivos são misturados em um certo proporção. Essa etapa geralmente usa equipamentos de mistura de alta eficiência para garantir a distribuição uniforme dos componentes e evitar a aglomeração. O tempo e a velocidade da mistura devem ser rigorosamente controlados durante o processo de mistura para garantir uma combinação suficiente de pó de alumínio e aditivos, criando uma boa base para as reações subsequentes.

Os materiais misturados precisam ser moídos para atingir o tamanho de partícula especificado. Essa etapa é fundamental para melhorar a atividade do pó de alumínio. O uso de moinhos de bolas ou outros tipos de equipamentos de moagem pode reduzir efetivamente o tamanho da partícula e aumentar a área de superfície do pó de alumínio, melhorando assim sua reatividade com a água. Após a moagem, os materiais também devem ser classificados para garantir a consistência do tamanho das partículas e da distribuição do produto.

Nessa etapa, o pó de alumínio moído é misturado com água e outros aditivos necessários para formar a pasta de alumínio. As condições de reação nesse momento (como temperatura e velocidade de agitação) precisam ser controladas para garantir que a reação entre o pó de alumínio e a água seja suficiente para gerar uma estrutura de bolhas estável. É possível obter melhor efeito de geração de gás e fluidez por meio de proporção e agitação razoáveis.

A pasta de alumínio aerada preparada (slurry) deve prestar atenção às condições ambientais durante o armazenamento e o transporte, evitando altas temperaturas e umidade para evitar reações prematuras e falhas. Suas propriedades físicas e químicas devem ser verificadas regularmente durante o armazenamento para garantir a estabilidade da qualidade do produto. Por fim, a pasta de alumínio deve ser embalada de acordo com os padrões para garantir que não ocorra nenhum vazamento ou deterioração durante o transporte.

No processo de produção de pasta de alumínio aerada (slurry)/pó, várias tecnologias importantes têm um impacto profundo no desempenho e na qualidade do produto final:

A moagem de bolas é um importante tecnologia para moagem de pó de alumínio. O processo de moagem física pode reduzir efetivamente o tamanho das partículas do pó de alumínio e aumentar sua área de superfície específica. Tamanhos menores de partículas ajudam a aumentar a reatividade do pó de alumínio, permitindo que ele gere gás hidrogênio mais rapidamente ao reagir com a água, formando assim uma estrutura de bolhas uniforme e estável.

Jogos de tecnologia de classificação um importante O papel da classificação é garantir a consistência da distribuição do tamanho das partículas do pó de alumínio. Por meio da classificação, os pós de alumínio de diferentes tamanhos de partículas podem ser separados, melhorando a atividade e a adaptabilidade do material. Uma distribuição adequada do tamanho das partículas pode otimizar a formação de bolhas e melhorar a resistência do concreto aerado e o desempenho do isolamento térmico.

No processo de preparação da pasta de alumínio, o controle das condições de reação (como temperatura e tempo) é fundamental. Condições razoáveis de reação podem garantir que a reação entre o pó de alumínio e a água seja suficiente para gerar um número adequado de bolhas distribuídas uniformemente. A aplicação da tecnologia de controle de reação ajuda a melhorar a estabilidade e a consistência do produto.

O desempenho do produto pode ser aprimorado por meio da otimização contínua da formulação da pasta de alumínio (slurry). Por exemplo, a adição de quantidades adequadas de determinados aditivos pode aumentar a taxa de reação do pó de alumínio e melhorar a fluidez e a estabilidade da pasta de alumínio. Além disso, para diferentes necessidades de aplicação, as empresas podem desenvolver vários tipos de pasta de alumínio para atender às diversas necessidades do mercado.

Na produção, o controle das condições ambientais (como temperatura e umidade) também é fundamental para garantir a qualidade do produto. Especialmente nos estágios de armazenamento e transporte, é necessário fornecer condições ambientais adequadas para evitar que a pasta de alumínio falhe ou se deteriore devido a mudanças ambientais.

O controle de qualidade é um importante O sistema de controle de qualidade é um elo em todo o processo de produção para garantir o desempenho estável da pasta de alumínio aerada (slurry)/pó. As empresas geralmente estabelecem um sistema completo de gerenciamento de qualidade, incluindo:

Antes do início da produção, todas as matérias-primas devem passar por uma rigorosa inspeção de qualidade para garantir que atendam aos padrões de produção. A atividade, a pureza e a distribuição do tamanho das partículas do pó de alumínio precisam ser testadas para determinar se ele atende aos requisitos de produção.

Durante o processo de produção, os parâmetros de cada estágio (como temperatura, umidade, tempo de mistura, etc.) são monitorados em tempo real para garantir que o processo de produção esteja sempre no melhor estado. Além disso, o equipamento de teste on-line pode detectar e ajustar problemas a tempo de evitar a geração de produtos não qualificados.

Depois que o produto é produzido, é necessário realizar testes abrangentes de desempenho do produto acabado, incluindo indicadores como fluidez, geração de gás e resistência à compressão, para garantir que ele atenda aos padrões relevantes e às necessidades do cliente. Somente os produtos que passaram por testes rigorosos podem ser colocados no mercado para venda.

Perguntas que os clientes costumam fazer quando procuram pasta de alumínio para fábricas de tijolos de concreto leve

1. Sua fábrica é uma Fabricante de pasta de alumínio para tijolos de concreto leve?

Resposta: Sim, somos um fabricante profissional de pasta de alumínio DEG com muitos anos de experiência em produção e tecnologia de produção avançada.

2. Quais são os índices de qualidade da pasta de alumínio para tijolos de concreto leve em sua fábrica?

Resposta: Os índices de qualidade da pasta de alumínio para tijolos de concreto leve em nossa fábrica são os seguintes:

Sólido contendo: 70±1

Tempo de aeração retardado: 1-3 minutos

Alumínio ativado: ≥92

Uniformidade do tamanho das partículas: alta

3. Qual é o preço da pasta de alumínio para tijolo de concreto leve em sua fábrica?

R: O preço da pasta de alumínio para tijolo de concreto leve em nossa fábrica depende do modelo específico e da quantidade. Entre em contato conosco para obter uma cotação detalhada.

4. Qual é a quantidade mínima de pedido de pasta de alumínio DEG em sua fábrica?

R: A quantidade mínima de pedido de polpa de alumínio DEG de nossa fábrica é de 1 tonelada, dependendo.

5. Que tipo de serviço pós-venda a pasta de alumínio para tijolos de concreto leve pode oferecer?

Resposta: Nossa fábrica oferece os seguintes serviços pós-venda:

Garantia de qualidade do produto

Orientação técnica

Rastreamento do serviço pós-venda

6. A pasta de alumínio para tijolos de concreto leve pode ser personalizada?

Resposta: Sim, podemos personalizar a produção da pasta de alumínio DEG de acordo com as exigências dos clientes.

Na Five Star Material, entendemos que cada projeto é único, e nosso objetivo é fornecer as melhores soluções personalizadas para cada cliente.

Entraremos em contato com você dentro de 24 horas.

Para consultas urgentes, entre em contato conosco pelo número do whatsapp: +86-13309617918