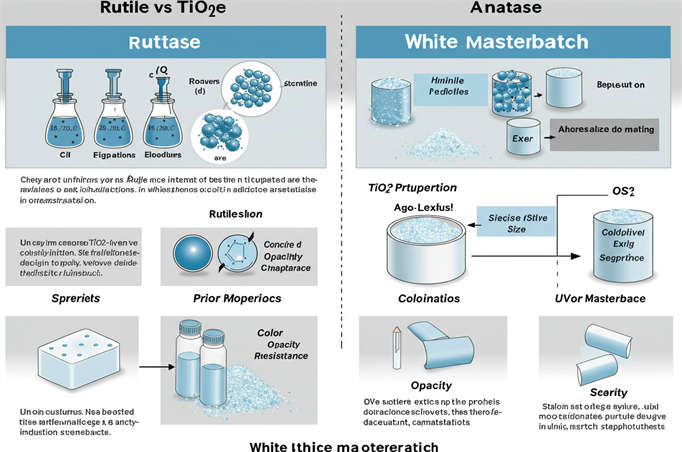

White masterbatch is a plastic colorant composed of high-concentration titanium dioxide (TiO₂, 30%-70%), carrier resin (e.g., PE, PP, PS), and dispersants. Manufactured via high-speed mixing, melt extrusion, and pelletizing, it ensures uniform dispersion in plastics, delivering excellent opacity and whiteness. Widely used in injection molding, film blowing, and fiber industries, it is applied in food packaging, appliance casings, and daily necessities. Compared to direct pigment addition, masterbatch enhances production efficiency, reduces dust pollution, and ensures color consistency. Eco-friendly variants comply with RoHS standards.

The Power of White Masterbatch in Modern Plastic Manufacturing

At Five Star New Materials, we understand that the backbone of innovative plastic manufacturing lies in the quality and versatility of the materials used. Белый мастербатч stands out as a cornerstone of modern plastic production. As a leading provider of high-performance plastic solutions, we преданные to exploring its transformative potential in enhancing product aesthetics, functionality, and sustainability.

White Masterbatch is more than just a coloring agent—it is a precision-engineered compound designed to deliver exceptional brightness, opacity, and durability to plastic products. From household appliances and packaging materials to automotive components and medical-grade applications, the demand for White Masterbatch continues to grow, driven by its ability to elevate product quality while reducing production costs.

In this blog, we delve into the world of White Masterbatch, exploring its production processes, technical challenges, market trends, and the critical factors that ensure its quality and performance. We also examine how Five Star New Materials leverages cutting-edge technology and sustainable practices to deliver White Masterbatch solutions that meet the highest industry standards. Whether you are a manufacturer seeking to enhance product aesthetics or a buyer looking for eco-friendly and high-performance materials, this blog will equip you with insights to make informed decisions.

Join us as we uncover the science, innovation, and future of White Masterbatch—a material that shapes the present and promises a brighter future for plastic manufacturing.

Introduction to White Masterbatch

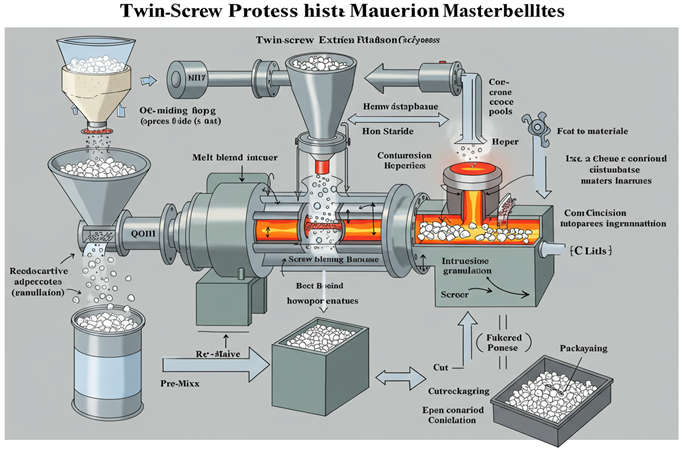

White Masterbatch is a plastic additive made from high-quality pigments, resins, and additives, refined through rapid processing and twin-screw extrusion. It is primarily used to color plastic products. It offers rich hues, strong color strength, excellent water permeability, high concentration, suitable particle size, strong coverage, good migration resistance, and high heat resistance.

White Masterbatch finds broad applications in injection molding, extrusion, film blowing, foaming, sheet, pipe, granulation, blow molding, EVA, and bottle blowing. It используется in various products, including household appliances, toys, packaging materials, power cables, bags, automobiles, building materials, sports and leisure goods, and bottles. In material science, White Masterbatch is key in improving plastic product color and performance, enhancing particle size, coverage, migration, and heat resistance, and boosting product quality, production efficiency, energy savings, and emissions reduction.

Production Process and Technical Highlights

Selection of Raw Materials

White Masterbatch Market and Brand Landscape

Market Demand

In 2023, the domestic market demand for White Masterbatch in China was approximately 18.5 billion yuan, and it is expected to reach 22 billion yuan by 2025, with a growth rate of 6.5%.

Focus of Competition

The main competition centers on environmental certifications (e.g., halogen-free, biodegradable) and user-friendly solutions (e.g., medical-grade masterbatches).

Development Directions of White Masterbatch

Ensuring the Quality of White Masterbatch in Production

To ensure the quality of White Masterbatch, strict control is necessary at various stages of production. The key measures include:

Additional Considerations

International White Masterbatch Brand Advantages

Impact and Insights for the Domestic Market

Global leading brands, through technological monopolies and environmental certifications, are pushing domestic companies to improve their competitive environment. However, this also accelerates China’s growth. For example, with its high-permeability White Masterbatch technology, Five New Materials has improved its position in mid-to-high-end markets, effectively challenging international restrictions.

Новые материалы Five Star—Your Partner in White Masterbatch Excellence

As we conclude our exploration of Белый мастербатч, it is clear that this versatile material is at the heart of modern plastic innovation. From enhancing product aesthetics to meeting stringent environmental and performance standards, White Masterbatch continues to evolve, driven by technological advancements and sustainability.

At Five Star New Materials, we take pride in being at the forefront of this evolution. Our White Masterbatch solutions are engineered to deliver unmatched quality, functionality, and consistency. By combining advanced production techniques with rigorous quality control, we ensure that our products meet the demands of diverse industries, from packaging and automotive to medical and aerospace applications.

We recognize that White Masterbatch’s future lies in its ability to adapt to emerging challenges—whether through functional integration, reduced environmental impact, or breakthroughs in high-performance applications. As a trusted partner, Five Star New Materials is committed to driving these innovations forward, offering tailored solutions that align with your needs and sustainability goals.

Whether you want to enhance product quality, reduce your environmental footprint, or explore new applications for White Masterbatch, we invite you to partner with us. With our global expertise, cutting-edge technology, and unwavering commitment to excellence, we are ready to support your journey toward a brighter, more sustainable future.

Contact Five Star New Materials today to discover how our White Masterbatch solutions can transform your manufacturing process and elevate your products to new heights

Мы предлагаем вам полностью пообщаться с нами перед покупкой, мы обязательно рассмотрим все аспекты и предоставим справедливый и разумный план цен. Выбрав нас, вы получите лучший продукт и лучшее соотношение цены и качества.

Choosing the right size of product gives you the best value for money. Our White Masterbatch is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

Чем больше количество товара, тем ниже цена за единицу товара. Объемные заказы позволяют нам лучше распределять производственные и операционные расходы, поэтому мы рады предложить скидки на оптовые закупки.

Сроки и способ оплаты, которые вы выберете, также повлияют на цену. Например, полная предоплата может привести к более выгодной цене, так как снижает стоимость капитала. Пожалуйста, обсудите наиболее подходящий вариант оплаты с нашим отделом продаж.

Транспорт и логистика также являются факторами, влияющими на общую стоимость владения. Разные виды транспорта и пункты назначения влекут за собой разные расходы на доставку. Также необходимо учитывать пошлины, страхование и другие расходы. Рассчитав эти факторы заранее, вы сможете более точно оценить общую стоимость.

В компании Five Star Material мы понимаем, что каждый проект уникален, и наша цель - предоставить наилучшие индивидуальные решения для каждого клиента.

Мы свяжемся с вами в течение 24 часов.

Для ваших срочных запросов, пожалуйста, свяжитесь с нами через Whatsapp No: +86-18001668319