Leafing aluminum paste gives a shiny, metallic look. It also has good weather resistance. But, it does not resist corrosion very well. It can be hard to recoat. These things are important for your project. The look, life, and how well it works depend on the material you pick. More people use leafing aluminum paste now. It is popular in cars and factories. People want strong coatings that last long. Think about the good and bad points before you choose.

Основные выводы

- Leafing aluminum paste makes things look shiny and bright. It looks like chrome and stays nice outside.

- It works best if you use only one layer. The flakes rise to the top, so it is hard to paint over it.

- This paste helps protect from sun damage. But it does not stop rust or scratches very well.

- Use leafing aluminum paste on cars, packages, and decorations. It is good when you want things to shine a lot.

- Be careful when you use and store the paste. It can make dust, so follow safety rules to keep people and nature safe.

Advantages of leafing aluminum paste

Metallic Finish

Leafing aluminum paste gives a bright, metallic look. The aluminum flakes rise to the top and make a mirror effect. This finish looks like chrome and makes cars and packages look fancy. Five Star Materials sells leafing aluminum paste with a steady metallic shine. Their product helps you get the same shiny look every time. Small changes in the paste can change the gloss and color. That is why Five Star Materials checks each batch to keep quality high.

Высокий глянец

Leafing aluminum paste makes surfaces very shiny. The flakes sit on top and bounce light back. This makes the coating look new and glossy. You see this in car paints and fancy packages. Experts check gloss by looking at samples and comparing them. Five Star Materials uses strict rules to keep gloss high. Their paste stays shiny even after a long time. Coatings with leafing aluminum paste keep up to 95% of their gloss after driving far. The flakes protect the coating from sun and chemicals. Your project stays bright and glossy for years.

Weather Resistance

Coatings need to last outside. Leafing aluminum paste helps protect things from rain, sun, and heat. The aluminum flakes make a shield that reflects UV rays and slows damage. Five Star Materials makes their paste to fight weather and UV light. Lab tests show coatings with leafing aluminum paste lose only a little gloss after months outside. After 1,000 hours of heat and UV tests, the loss is less than 2%. This means your coatings stay strong and shiny in tough weather.

Совет: Leafing aluminum paste works best in single-layer coatings. It gives a bright finish and good weather resistance.

Here is a table comparing UV resistance between leafing and non-leafing aluminum paste:

| Аспект | Алюминиевая паста для литья | Алюминиевая паста, не вызывающая нареканий |

|---|---|---|

| UV Resistance and Durability | Makes a shiny top layer that reflects UV but can break down over time; flakes may fall off after lots of UV or many coats | Flakes spread through the coating, stick better, and protect against cracks and fading; keeps its look longer under UV |

| Appearance under UV Exposure | Bright, chrome-like finish at first, but can break down and lose flakes | Softer, satin metallic look that stays strong and lasts |

| Suitability for Long-Term UV Exposure | Best for single-layer use where shine matters but does not last as long | Best for many layers needing strong UV protection and lasting power |

| Test and Industrial Experience Summary | Tests and work experience show non-leafing pastes last longer and resist UV better | Non-leafing pastes have better UV resistance and last longer in tests and real use |

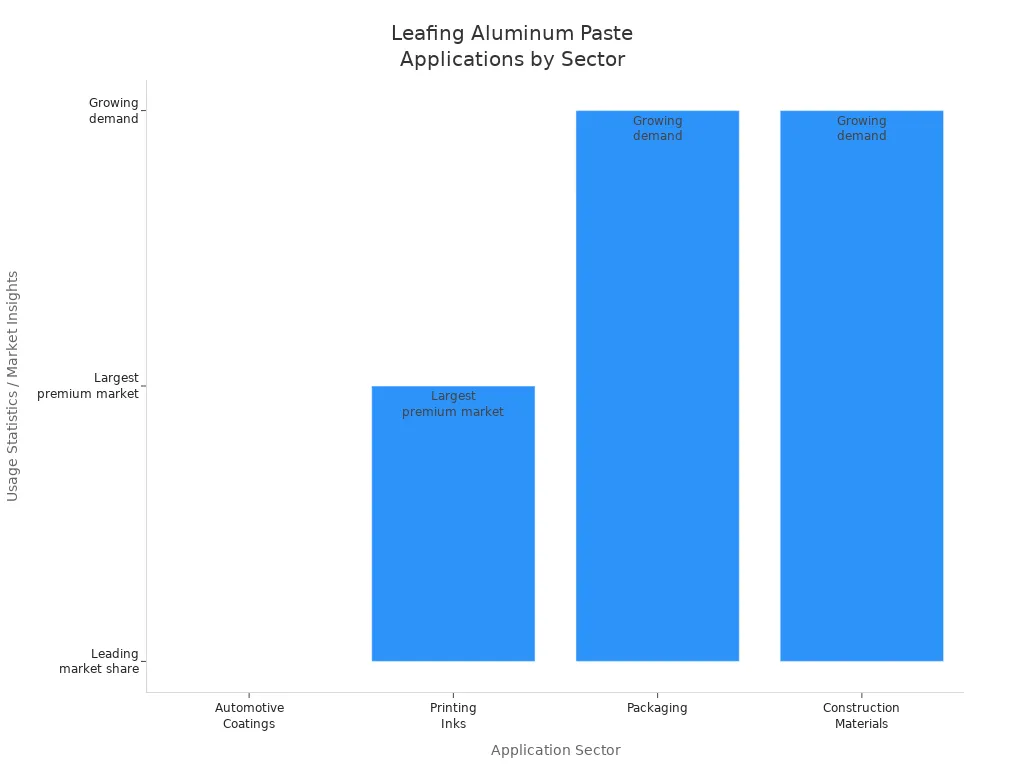

Application Uses

Leafing aluminum paste is used in many industries. It works in car coatings, printing inks, packaging, and building materials. Five Star Materials sells paste for all these jobs. Their product gives strong metallic looks, weather protection, and easy use. The market for leafing aluminum paste is growing fast, especially in Asia-Pacific, because cars and buildings need it. The paste is also liked in fancy packages and electronics for its shiny look.

Car coatings and printing inks use the most leafing aluminum paste. The market was $1.2 billion in 2024 and may reach $2.1 billion by 2033. Five Star Materials helps you meet tough quality rules in these areas.

| Feature/Property | Description/Benefit | Области применения |

|---|---|---|

| Strong Metallic Luster | Bright, fancy metallic look | Car, coil, appliance, machine coatings |

| Excellent Acid and Weather Resistance | Lasts 5–7 years outside | Outdoor paints and coatings |

| Concentrated Particle Size Distribution | Steady metallic sparkle | Paints, coatings, inks |

| Superior Dispersion Safety | Spreads evenly, easier to use | Paints, coatings, inks |

| Application Versatility | Used in plastics, inks, decorations | Paints, coatings, inks, plastics, decorations |

Cost Benefits

You save money with leafing aluminum paste for big jobs. The paste lasts longer and means fewer repairs. Five Star Materials sells products that help you spend less by making coatings stronger. The market for leafing aluminum paste is growing because it helps makers cut down on fixing and replacing things. You get a strong, shiny finish that stays bright, so you spend less over time. This makes leafing aluminum paste a smart pick for cars, buildings, and packages.

Disadvantages of leafing aluminum paste

Устойчивость к коррозии

Leafing aluminum paste does not stop corrosion well. The flakes float up and make a shiny layer. This layer does not seal the surface all the way. Water and air can slip through tiny spaces between the flakes. Over time, rust or other damage can happen. This is worse in wet or salty places. If you need strong protection, try other aluminum paste types or add more layers.

Recoatability Issues

If you want to add more paint layers, you may have trouble. The flakes move to the top and make a smooth, shiny coat. This looks nice but makes new layers hard to stick. The bond between coats is weak. The new paint may peel or flake off. This is a big problem for projects with many coats, like cars or factories.

Here is a table that compares leafing and non-leafing aluminum pastes in multilayer systems:

| Характеристика | Алюминиевая паста для литья | Алюминиевая паста, не вызывающая нареканий |

|---|---|---|

| Flake Behavior | Flakes float to the surface, creating a bright, chrome-like finish | Flakes disperse evenly throughout the film, producing a satin metallic sheen |

| Mechanical Strength | Slightly weaker paint film due to surface flake orientation | Stronger film with flakes integrated in resin matrix |

| Recoatability | Difficult; poor inter-coat adhesion, challenging to apply additional layers | Excellent; designed for good inter-coat adhesion and recoating |

| Типичные области применения | Single-coat protective or decorative finishes (e.g., storage tanks) | Multilayer systems requiring clear topcoats, such as automotive paints |

Нанесение алюминиевой пасты works best for single-layer coatings. If you need more layers, non-leafing aluminum paste is better.

Устойчивость к истиранию

Leafing aluminum paste gives a bright look. But it does not resist scratches or rubbing well. The flakes sit on top and can wear away fast if touched or cleaned often. The finish may look dull or patchy after some time. If you need a tough surface, use another coating or add a clear layer.

Adhesion Problems

Coatings with leafing aluminum paste may not stick well. The shiny flake layer makes it hard for the coating to grip the base. This can cause peeling, flaking, or uneven spots. You may also have trouble painting over it later. To help it stick better, prepare the surface or use special primers.

Примечание: Test the coating on a small spot first. This helps you find sticking problems before you start a big job.

Environmental Concerns

When you use or store leafing aluminum paste, think about safety and the environment. The paste can make dust. Breathing dust is bad and it can catch fire. Use closed systems and special vacuums to control dust. Store the paste in airtight, grounded containers away from water and chemicals. Keep the storage area cool, dry, and with good airflow.

Handle waste with care. Never mix aluminum paste waste with water or chemicals. Use closed containers and follow local rules for hazardous waste. Recycling helps cut down pollution. Wear gloves, goggles, and protective clothes to stay safe.

- Control dust to stop health risks and explosions.

- Store aluminum paste in airtight, grounded containers away from water, oxidizers, and flammable liquids.

- Keep storage areas cool, dry, and with good airflow.

- Put waste in closed containers and keep it dry.

- Never mix waste with water or chemicals.

- Use recycling and follow hazardous waste rules.

- Wear safety gear to avoid skin and breathing problems.

- Fire risks exist because of flammable solvents; never use water on aluminum paste fires.

If you follow these steps, you can use leafing aluminum paste safely and help protect the environment.

Comparison Table

Pros vs Cons

When you pick a coating, you need to know the good and bad sides. The table below shows the main pros and cons of листовая алюминиевая паста. This helps you see if it is right for your project.

| Характеристика | Pros of Leafing Aluminum Paste | Cons of Leafing Aluminum Paste |

|---|---|---|

| Внешний вид | Bright, mirror-like metallic finish | Can lose shine if scratched or worn |

| Gloss | High gloss, eye-catching look | Gloss may fade with heavy use |

| Weather Resistance | Reflects UV rays, slows sun damage | Not as durable in harsh conditions |

| Приложение | Easy to use in single-layer coatings | Hard to recoat or add more layers |

| Расходы | Cost-effective for decorative jobs | May need extra products for protection |

| Устойчивость к коррозии | Some protection from weather | Water and air can cause corrosion |

| Adhesion | Good for first coat | Poor grip for extra coats |

| Устойчивость к истиранию | Shiny surface for light use | Flakes wear off with rubbing or cleaning |

| Environmental/Safety | Easy to recycle, long shelf life | Dust can be hazardous, needs safe storage |

Совет: If you want a finish that lasts a long time, non-leafing aluminum pastes are better. These flakes mix into the paint and do not float up. You get a softer shine, but the finish stays strong and does not wear out fast.

Non-leafing aluminum pigments cover better and stick stronger. They also last longer in bad weather. These pigments do not come off as easily as leafing types. This makes them a good pick for surfaces that need to look nice and last a long time. More people use non-leafing pigments now because they want coatings that stay safe and strong.

Think about what your project needs. If you want a bright, shiny look for one layer, листовая алюминиевая паста is a good choice. If you need more strength and longer life, non-leafing types might be better. Five Star Materials sells both, so you can choose what works best for your job.

When to Use leafing aluminum paste

Best Applications

Нанесение алюминиевой пасты is used in many fields. It is best for jobs that need a shiny, metallic look and good weather resistance. Here are some top uses:

- First coatings for cars and machines

- Coatings to stop rust on metal

- Plastic coatings for toys and home items

- Food packages that need to look shiny

- Printing for bold designs on fabric or paper

- Fancy coatings for furniture and signs

- Rim coatings for wheels and car parts

- AAC blocks in building work

You get the best results if you clean and dry the surface first. For small areas, use a brush. For big areas, spraying or screen printing works better. Put on thin, even coats to make the shine smooth. Always follow the drying steps from the maker. Материалы Five Star has products that help you meet these rules and get a steady finish.

Совет: If you want a mirror shine and only need one coat, leafing aluminum paste is a great pick.

When to Avoid

Some jobs do not work well with leafing aluminum paste. Do not use it in these cases:

- You use strong polar solvents or binders. These can break the leafing effect and make it dull.

- You need strong mixing. This can break the thin flakes and cause spots or changes.

- Your formula uses chlorinated hydrocarbons. These can react with aluminum and cause trouble.

- You want to use water-based coatings. Leafing aluminum paste does not mix well with water unless you use special stabilizers.

- You need many coats or strong sticking between layers. Leafing aluminum paste is best for single-layer jobs.

If you need a coating that lasts longer, sticks better, or works with water, pick another type. Always test your formula before you start a big job.

| Situation | Use Leafing Aluminum Paste? | Why? |

|---|---|---|

| Single-layer, shiny finish | ✅ | Gives bright, metallic look |

| Water-based coating system | ❌ | Needs special stabilization |

| High mechanical mixing | ❌ | Flakes can break and lose effect |

| Food packaging | ✅ | Safe and decorative when applied properly |

| Multi-layer coatings | ❌ | Poor adhesion between layers |

🛑 Note: Always check your materials and steps before you use leafing aluminum paste. This helps you avoid problems and get the best results.

You now know the good and bad sides of leafing aluminum paste. It gives a shiny, metallic look and stands up to weather. But it might not last long in tough places or with many coats. When you choose, remember these things:

- The shiny look you want for your project

- How you will put on the paste

- Safety rules and how it affects the environment

- How much you want to spend now and later

If you think about these things, you can pick the right coating for your job. Five Star Materials has choices that fit what you need and want.

Часто задаваемые вопросы

What is leafing aluminum paste used for?

Нанесение алюминиевой пасты makes things look shiny and metallic. People use it in car paint, packages, and decorations. It gives a bright, mirror-like finish that catches your eye.

Can you recoat over leafing aluminum paste?

It is hard to paint over leafing aluminum paste. The flakes make a smooth layer. New paint does not stick well. It works best as a single-layer finish.

Is leafing aluminum paste safe to handle?

You need to be careful with leafing aluminum paste. Wear gloves and a mask to keep dust away. Store it in a cool, dry spot. Always follow safety rules from Five Star Materials.

How do you apply leafing aluminum paste?

You can brush, spray, or print leafing aluminum paste. Clean and dry the surface first. Thin and even coats give the best shine.

Does leafing aluminum paste resist corrosion?

Leafing aluminum paste helps protect against weather. It does not stop corrosion all the way. For strong rust protection, use extra coatings or pick another product.