Хромированная алюминиевая пастаизвестная своим высоким блеском и зеркальной поверхностью, стала популярной в различных отраслях промышленности, особенно в автомобильной. В этом блоге мы рассмотрим уникальные свойства алюминиевой пасты Chrome, области ее применения и преимущества, которые она дает. Мы рассмотрим, как эта специальная алюминиевая паста может улучшить внешний вид и эксплуатационные характеристики автомобильных красок, а также предоставим полный обзор ее преимуществ и способов применения.

Алюминиевая паста с хромированной полировкой

Хромированная полированная алюминиевая паста - это специализированная алюминиевая паста со следующими характеристиками и областями применения:

Характеристики товара

- Высокий глянец: Хромированная алюминиевая паста создает покрытие с эффектом, напоминающим хром, обеспечивая исключительный блеск и зеркальную поверхность.

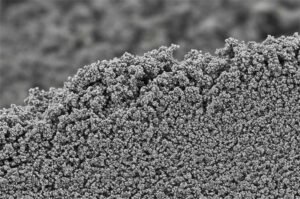

- Ультратонкие алюминиевые хлопья: Этот продукт состоит из ультратонких алюминиевых хлопьев с минимальной толщиной и однородной поверхностью, образующих гладкое покрытие.

- Отличное покрытие: Паста обеспечивает сильное покрытие, скрывая основной материал и обеспечивая равномерный внешний вид.

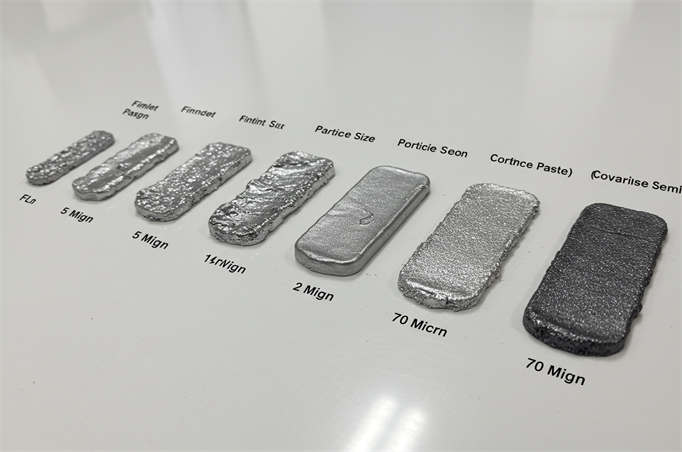

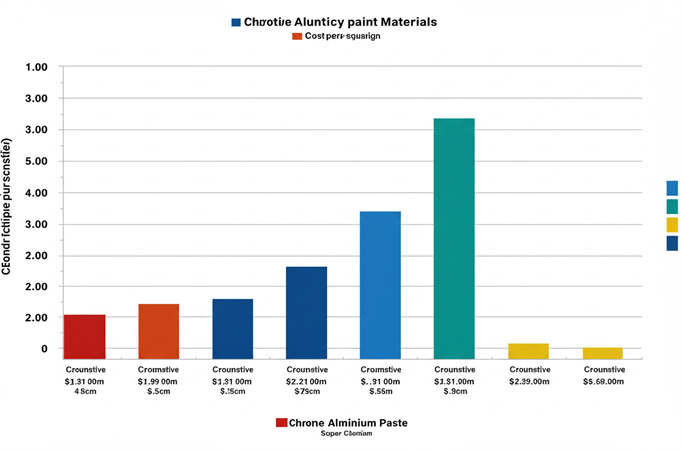

- Разнообразие размеров частиц: Различные модели хромированной алюминиевой пасты имеют различный размер частиц (D50 от 5 до 12 микрон), что позволяет удовлетворить самые разнообразные потребности.

- Зеркало с эффектом хрома: Благодаря специализированным процессам паста приобретает глянцевый зеркально-металлический блеск, который обычно используется в автомобильных красках, пластиковых покрытиях и печатных красках. Регулировка размера частиц (5-70 мкм) и дисперсности усиливает визуальную привлекательность пасты, подобно гальваническому покрытию.

Классификация и процесс

- Тип листания: Алюминиевая пудра всплывает на поверхность покрытия, образуя высокоотражающий слой, идеально подходящий для антикоррозионных покрытий и металлического декора.

- Нелистопадный тип: Алюминиевая пудра равномерно распределяется по всему покрытию, идеально подходит для работ, требующих равномерной металлической текстуры, например, для автомобильных красок.

Области применения

- Устройства для рукоделия: Применяйте пасту для напыления и печати, чтобы придать изделиям из дерева превосходный хромированный эффект и декоративную привлекательность.

- Декорирование мебели: Используйте хромированную алюминиевую пасту в отделке мебели, чтобы обеспечить глянцевую поверхность, повышая эстетику изделия.

- Корпуса для приборов: Нанесите эту пасту на корпуса приборов, таких как панели холодильников, телефоны и линзы, чтобы добиться превосходного зеркального эффекта.

- Промышленные покрытия: Используйте пасту в промышленных покрытиях для получения зеркальных хромовых красок для различных металлических поверхностей.

- Краски для печати и косметика:

- Чернила: Используйте зеркальную алюминиевую пасту при печати упаковки для создания блестящего металлического эффекта.

- Товары для ногтей: Используйте пасту в качестве ключевого ингредиента в хромированном лаке для ногтей, чтобы получить ослепительную металлическую текстуру.

- Строительные материалы: Использование алюминиевой пасты в газобетоне (AAC) для выделения водорода, образующего пористую структуру, которая снижает вес и улучшает теплоизоляцию.

Производственный процесс

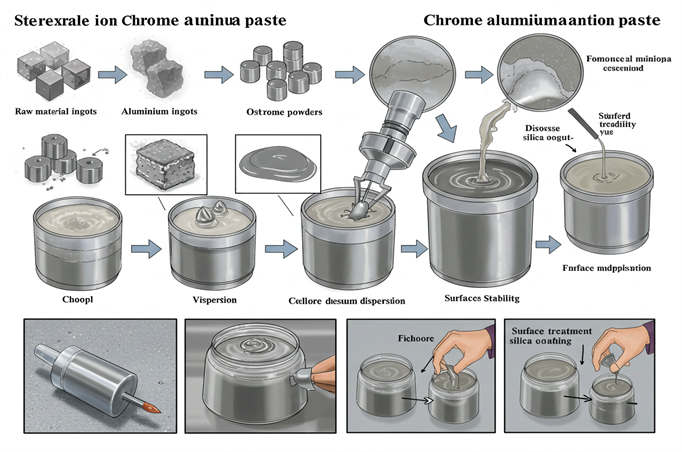

Производители изготавливают хромированную алюминиевую пасту, выполняя следующие действия:

- Выбор сырья: Выбирайте алюминий высокой чистоты, чтобы обеспечить качество и производительность продукта.

- Вакуумное осаждение: Нанесение алюминия на подложку с помощью вакуумного испарения для создания однородной алюминиевой пленки.

- Пульверизация: Измельчите осажденную алюминиевую пленку до ультратонких чешуек.

- Обработка поверхности: Обработка поверхности алюминиевых хлопьев, например, покрытие слоем диоксида кремния, для повышения стабильности и устойчивости к атмосферным воздействиям.

Сопутствующие методы обработки поверхности

- Анодирование и гальваническое покрытие: Анодируйте алюминий для повышения коррозионной стойкости или нанесите гальваническое покрытие для получения хромированного эффекта.

- Процесс полировки: Нанесите полировочные составы для металла (например, аэрозольные), чтобы вернуть первоначальный блеск алюминиевым изделиям.

- Промышленное литье и обработка: Такие компании, как Alcast в США, предлагают литье в постоянные формы для алюминия, что является идеально подходит для производства сложных металлических деталей.

Преимущества хромоалюминиевой пасты в автомобильной краске

1. Эстетическая привлекательность

- Уникальный металлический блеск: Хромированная алюминиевая паста придает автомобильной краске характерный металлический блеск и текстуру, придавая кузову автомобиля пленительный серебристый или мерцающий под светом вид, повышая его общую красоту и роскошь.

- Цветовое смещение в зависимости от угла: Смешайте пасту с прозрачными пигментами для создания поразительного эффекта "изменения цвета в зависимости от угла обзора", когда цвет меняется в зависимости от угла обзора, обеспечивая роскошную декоративную отделку.

2. Устойчивость к коррозии

- Сильное покрытие: Паста обеспечивает превосходное покрытие, эффективно скрывая основной материал и придавая ему однородный вид, защищая кузов автомобиля от вредного воздействия окружающей среды.

- Коррозионная стойкость: Образует плотное покрытие, которое блокирует влагу, кислород и другие агрессивные вещества, продлевая срок службы автомобиля.

3. Экологические и энергетические преимущества

- Алюминиевая паста на водной основе: В связи с растущей заботой об окружающей среде алюминиевая паста на водной основе становится все более популярной в автомобильных красках. Она хорошо сочетается с водными растворителями, соответствует экологическим стандартам и снижает потребление тепла при запекании, что значительно сокращает потребление энергии на производстве.

- Низкий уровень выбросов летучих органических соединений: Паста на водной основе минимизирует выбросы летучих органических соединений (ЛОС), что делает ее более безопасной для окружающей среды.

4. Производительность приложения

- Хорошая дисперсность: Хромированная алюминиевая паста равномерно распределяется в покрытии, обеспечивая равномерное и однородное покрытие.

- Стабильность: Остается в краске, не оседая и не наслаиваясь, упрощая нанесение и хранение.

5. Экономическая эффективность

- Высокое соотношение цены и качества: Несмотря на превосходные декоративные эффекты и отличные эксплуатационные характеристики, хромированная алюминиевая паста имеет относительно невысокую стоимость, обеспечивая высокую ценность и удовлетворяя разнообразные запросы потребителей.

6. Инновационное использование

- Специальные эффекты: Обработка пасты с помощью уникальных технологий для создания эффектов смещения света и тени на кузове автомобиля под определенным углом, что усиливает визуальное воздействие.

- Индивидуальная настройка: По мере роста спроса на индивидуальную эстетику автомобиля хромированная алюминиевая паста предлагает различные цвета и эффекты для удовлетворения индивидуальных предпочтений.

7. Превосходные экологические характеристики

- Совместимость с системами на водной основе: Паста адаптируется к системам окраски автомобилей на водной основе, снижая выбросы летучих органических соединений и соответствуя требованиям экологической модернизации отрасли. Серебряная паста на водной основе, покрытая неорганическим кремнеземом, отличается стабильностью хранения в течение 6-12 месяцев и сокращает потребление энергии на производстве более чем на 40%.

- Замена традиционному гальваническому покрытию: Имитирующая гальваническое покрытие алюминиевая паста обеспечивает зеркальный эффект с высокой отражающей способностью, заменяя традиционное хромовое гальваническое покрытие, предотвращая загрязнение тяжелыми металлами и соответствуя нормам ЕС RoHS.

8. Исключительный Зеркало с эффектом хрома

- Глянцевая металлическая текстура: Регулировка размеров частиц алюминия (5-70 мкм) и методы диспергирования позволяют формировать на лакокрасочных поверхностях зеркальную отделку, напоминающую гальваническое покрытие, что подчеркивает премиальный вид автомобиля. Например, имитирующая гальваническое покрытие паста отражает струящийся блеск при солнечном свете, создавая сильный визуальный эффект.

- Стойкость цвета: Паста устойчива к высоким температурам и атмосферным воздействиям, сохраняя ярко-белый цвет при длительном воздействии ультрафиолета или высокотемпературном запекании.

9. Преимущества производительности процесса

- Сильное покрытие и адгезия: Частицы пасты равномерно диспергируются, образуя плотное покрытие, превосходящее по укрывистости стандартные пигменты. Она прочно соединяется со смоляными системами, повышая устойчивость к царапинам.

- Адаптация к сложным приложениям: Нелетучая паста равномерно распределяется в лакокрасочной пленке, что делает ее пригодной для нанесения на сложные конструкции, такие как колеса и изогнутые поверхности кузова, и при этом противостоит кислотным дождям и коррозии от промышленного смога.

Таким образом, хромоалюминиевая паста в автомобильной краске улучшает эстетику и роскошь автомобиля, обеспечивает надежную защиту от коррозии, экологические и энергосберегающие преимущества, а также гарантирует отличную эффективность нанесения, что делает ее жизненно важным материалом в данной области.

Как хромированная алюминиевая паста улучшает адгезию лакокрасочного покрытия

1. Улучшение свойств краски

- Снижение вязкости краски: Снижение вязкости улучшает текучесть краски и ее проникновение в неровности и поры поверхности подложки, повышая адгезию к основному материалу.

- Снижение поверхностного натяжения: Хорошее смачивание предшествует прочной адгезии. Снижение поверхностного натяжения позволяет краске тщательно смачивать основание, особенно на небольших участках контакта, улучшая сцепление. Снижение вязкости также уменьшает поверхностное натяжение, так как растворители обычно имеют более низкое поверхностное натяжение, чем пленкообразующие полимеры.

2. Подготовка поверхности субстрата

- Очистите поверхность субстрата: Удалите масло и загрязнения с поверхности подложки. Они могут снижать поверхностное натяжение и препятствовать достаточному смачиванию материала, что приводит к плохой адгезии.

- Увеличение поверхностной энергии субстрата: Чтобы добавить активные участки и значительно повысить адгезию покрытия, необходимо соответствующим образом повысить поверхностную энергию подложки без ущерба для других свойств лакокрасочной пленки.

3. Использование промоторов адгезии

- Специализированные добавки: Добавьте промоторы адгезии, такие как APW, DY221 или LTH, чтобы значительно улучшить связь между алюминиевой пастой и подложкой:

- Тип APW: Включают полярные группы для усиления химической связи с металлическими подложками, а добавка 2-5% улучшает межслойную адгезию.

- Тип DY221: Решают проблемы отслаивания алюминиевой пасты в системах на водной или масляной основе, а добавка 0,2-2% повышает стойкость к отслаиванию.

- Модификация смолы: Используйте модифицированные смолы, такие как силиконовые соединения или стеарат сорбитана, для оптимизации совместимости между алюминиевой пастой и краской, улучшения выравнивания и адгезии.

- Высокомолекулярные полимеры: Полимеры с множеством органических функциональных групп, высокими значениями OH и кислот, а также уникальной гибкостью для улучшения адгезии к металлическим, неорганическим или пластиковым субстратам. Некоторые высокомолекулярные промоторы адгезии также улучшают связывание серебра и устойчивость к спирту в красках на основе алюминиевой пасты.

4. Оптимизация техники нанесения

- Предварительная обработка поверхности: Для окраски алюминиевых сплавов отшлифуйте поверхность или нанесите грунтовку, чтобы решить проблемы с адгезией и предотвратить отслаивание. Шлифовка создает шероховатость поверхности для лучшего сцепления краски с поверхностью, а грунтовка улучшает проникновение и сцепление верхнего слоя краски с металлической поверхностью.

- Контроль параметров покрытия: Управляйте вязкостью краски, температурой окружающей среды, влажностью и производительностью оборудования, чтобы повлиять на адгезию. Поддерживайте умеренную вязкость - слишком высокая или низкая ослабляет адгезию. Обеспечьте подходящую температуру и влажность, так как экстремальные значения ухудшают сушку и отверждение. Поддерживайте толщину покрытия на уровне 5-12 мкм, так как слишком толстые слои увеличивают когезию и снижают адгезию. Оптимизируйте температуру запекания (обычно 80-150°C), чтобы избежать быстрого сшивания и усадочных напряжений.

- Условия сушки и отверждения: Контролируйте методы сушки, способы спекания и толщину алюминиевой пленки, чтобы повлиять на адгезию. Установите соответствующую температуру и время сушки - слишком высокая или низкая температура влияет на адгезию. Регулируйте температуру и продолжительность спекания, поскольку чрезмерное тепло или время снижают адгезию.

- Усовершенствование техники распыления: Используйте электростатическое распыление (ESTA) для равномерного распределения частиц алюминиевой пасты, увеличивая плотность пленки. Отрегулируйте системы растворителей (например, терпинеол или бутил). карбитол ацетат) для снижения поверхностного натяжения и улучшения смачиваемости.

Типичные примеры применения

- Покрытие для автомобильных колес: Сочетайте промоутер APW с предварительной плазменной обработкой для достижения адгезии 5B.

- Алюминиевая паста для солнечных батарей: Модифицируйте никелевым порошком и бессвинцовой стеклянной фриттой для достижения адгезии >5N и деформации <0,5 мм после спекания.

Как создать зеркальный эффект с помощью хромированной алюминиевой пасты

Чтобы добиться зеркального эффекта при использовании хромированной алюминиевой пасты, подходите к выбору пасты комплексно, рецептура краски, техники нанесения и подготовки основания. Следуйте этим шагам и рекомендациям:

1. Выберите подходящую хромированную алюминиевую пасту

- Размер частиц: Для получения великолепного зеркального эффекта выбирайте хромированную алюминиевую пасту с размером частиц 3-5 микрон.

- Тип продукта: Выбирайте нелиняющие пигменты, чтобы избежать всплывания покрытия и создать равномерную зеркальную поверхность.

2. Оптимизация рецептуры краски

- Выбор смолы: Выберите зеркальную серебряную смолу с низким уровнем кислотности, чтобы эффективно сочетаться с алюминиевой пастой и усилить зеркальный эффект.

- Выбор растворителя: Используйте растворители с градиентом летучести, чтобы обеспечить гладкую зеркальную поверхность во время сушки.

- Добавки: Добавьте небольшое количество антиосадочных агентов для улучшения стабильности алюминиевой пасты в краске.

3. Подготовьте поверхность субстрата

- Очистите поверхность: Убедитесь, что подложка очищена от масла и грязи, очистив ее растворителями или химическими средствами.

- Шероховатость поверхности: Слегка увеличивает шероховатость поверхности для улучшения адгезии краски, продлевая долговечность зеркального эффекта.

4. Техника нанесения

- Метод применения: Нанесите краску распылением, шелкографией или валиком. При распылении соблюдайте необходимое расстояние между краскопультом и основанием для равномерного распределения.

- Толщина покрытия: Контролируйте толщину покрытия - слишком толстое или тонкое покрытие влияет на зеркальный эффект. Ориентируйтесь на 5-10 микрон.

- Условия сушки: Регулируйте температуру и влажность во время сушки, чтобы предотвратить появление таких дефектов поверхности, как апельсиновая корка или кратеры.

5. Постобработка

- Полировка: Отполируйте высохшее покрытие, чтобы повысить гладкость и зеркальность поверхности.

- Защитное покрытие: Нанесите прозрачное верхнее покрытие поверх зеркального слоя для повышения долговечности и устойчивости к царапинам.

Хромированная алюминиевая паста - это замечательный материал, который обладает множеством преимуществ, от повышения эстетической привлекательности автомобильных красок до обеспечения превосходной коррозионной стойкости и экологических преимуществ. Понимая его особенности и сферы применения, вы сможете использовать этот инновационный продукт для достижения потрясающих зеркальных эффектов и повышения общего качества ваших проектов. Будь то автомобильная промышленность или любая другая сфера, где важна высококачественная отделка, алюминиевая паста Chrome станет ценным дополнением к вашему набору инструментов.

Поднимите свои проекты на новый уровень с помощью хромированной алюминиевой пасты от 5 Star Materials

Готовы ли вы придать блеск своим покрытиям, автомобильным краскам или декоративной отделке с помощью хромированной алюминиевой пасты? Компания 5 Star Materials предлагает передовые решения в области алюминиевых паст, которые обеспечивают высокий блеск, зеркальный эффект и исключительную производительность для ваших приложений. Вдохновившись невероятными характеристиками и преимуществами нашего блога, такими как потрясающий металлический блеск, надежная коррозионная стойкость и экологические преимущества, сейчас самое время воплотить свое видение в реальность с помощью наших продуктов премиум-класса.

Наша хромированная алюминиевая паста отличается ультратонкими хлопьями, превосходным покрытием и настраиваемым размером частиц (от 3 до 70 микрон), что делает ее идеальным выбором для таких отраслей, как автомобилестроение, мебель, бытовая техника и т. д. Если вы хотите создать роскошную отделку автомобиля с зависящим от угла наклона цветовым сдвигом или улучшить промышленные покрытия с помощью прочного эффекта зеркального хрома, компания 5 Star Materials обладает опытом и продукцией для удовлетворения ваших потребностей. Наши листовые и нелистовые типы отвечают конкретным требованиям - высокая отражающая способность для декоративного блеска или однородная текстура для бесшовной интеграции, - обеспечивая универсальность ваших проектов.

Компания 5 Star Materials ставит во главу угла качество и инновации. Наш производственный процесс, от вакуумного напыления до передовой обработки поверхности, такой как покрытие кремнеземом, гарантирует стабильность, устойчивость к атмосферным воздействиям и простоту применения. Хотите повысить адгезию лакокрасочного покрытия? Сочетайте нашу хромоалюминиевую пасту с такими промоторами адгезии, как APW или DY221, или используйте нашу совместимость с системами на водной основе, чтобы снизить выбросы летучих органических соединений и затраты на электроэнергию - идеальный вариант для экологически сознательных людей. производители алюминиевой пасты. Наши варианты имитации электропокрытия представляют собой экологичную альтернативу традиционному хромированию, соответствующую строгим нормам, таким как EU RoHS.

Готовы создать безупречный зеркальный эффект? Начните с нашей пасты с мелкими частицами (3-5 микрон), оптимизируйте рецептуру с помощью смол с низким содержанием кислот и нанесите точное покрытие с помощью таких технологий, как электростатическое распыление. Наша команда поможет вам на каждом этапе - подготовка подложки, контроль толщины покрытия и последующая обработка - чтобы ваше покрытие было ослепительным. Имея более чем десятилетний опыт поставок высокоэффективных пигментов, компания 5 Star Materials является вашим надежным партнером для достижения результатов профессионального уровня.

Не довольствуйтесь обычным. Свяжитесь с 5 Star Materials сегодня, чтобы изучить наш ассортимент хромоалюминиевых паст и запросить образец, разработанный для вашей области применения - автомобильных красок, печатных красок или строительных материалов, таких как AAC. Посетите наш сайт по адресу 5starmaterials.com чтобы узнать больше о технических характеристиках нашей продукции и технической поддержке. Мы помогли промышленным предприятиям по всему миру создать блестящие металлические решения. Давайте сотрудничать, чтобы улучшить эстетику, долговечность и экологичность вашей продукции. Свяжитесь с нами через форму обратной связи или позвоните нашей команде экспертов, чтобы обсудить ваш следующий проект. С 5 Star Materials блеск - это всего лишь покрытие, действуйте сейчас и сияйте ярче, чем когда-либо!