Choosing the right aluminum paste in plastic decoration is crucial for achieving the desired aesthetic and functional properties. With a wide range of aluminum pastes available, it’s essential to understand the key factors that influence their selection. This blog post will guide you through selecting the most suitable aluminum paste for plastic applications, covering aspects such as paste type, performance, compatibility, processing adaptability, environmental requirements, and cost considerations. We will also explore the differences between oil-based aluminum paste and solvent-free aluminum silver strips and highlight the emerging trends in selecting aluminum paste for plastic decoration.

How to Choose the Right Aluminum Paste for Plastics

Selecting the right aluminum paste for plastics requires considering several factors. Here are some key points:

1. Types of Aluminum Paste

- Water-based Aluminum Paste: Suitable for water-based plastic products such as water-based paints and inks. It offers excellent moisture resistance, anti-aging properties, acid and alkali corrosion resistance, and superior environmental performance.

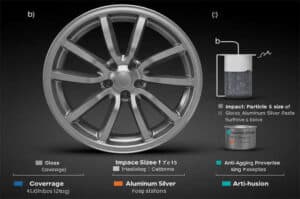

- Oil-based Aluminum Paste: Suitable for oil-based plastic products such as oil-based paints and inks. It has strong coverage and metallic texture but is less environmentally friendly.

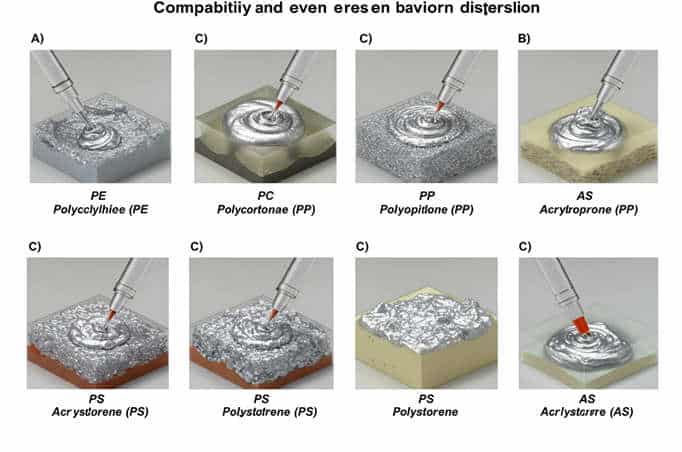

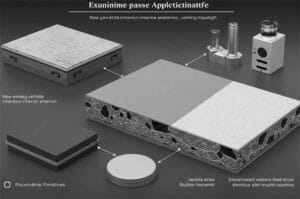

- Non-Spray Aluminum Silver Strips: Specifically used in plastic injection molding and masterbatch industries, it is compatible with PE, PC, PP, ABS, PS, and AS plastics. It features odorless properties, ease of dispersion, and easy processing.

2. Aluminum Paste Performance

- Coverage: Using a high-coverage aluminum paste can reduce the amount needed, saving costs while ensuring the product’s appearance meets inspection standards.

- Whiteness and Metallic Effect: Choose an aluminum paste with high whiteness and strong metallic effect according to the product’s appearance requirements to enhance the aesthetics.

- Particle Size Distribution: Aluminum paste with a narrow particle size distribution has better dispersion stability and provides a more uniform metallic effect.

3. Compatibility with Plastics

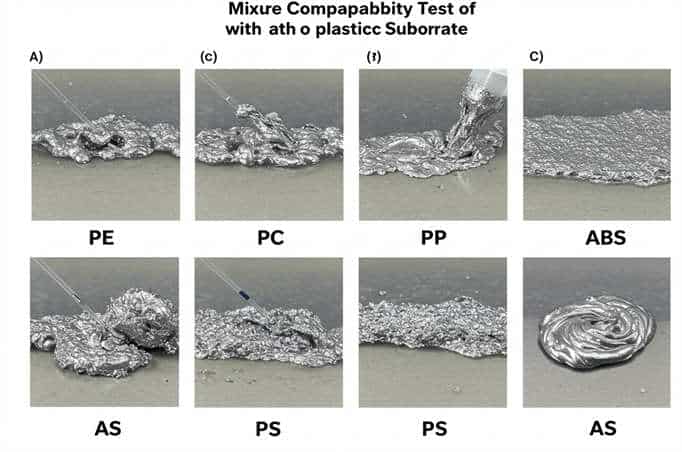

- Media Compatibility: Choose aluminum paste highly compatible with plastic substrates to ensure even dispersion in the plastic and avoid issues such as delamination or peeling.

- Обработка поверхности: Using aluminum paste with appropriate surface treatment improves adhesion and aging resistance with the plastic.

4. Adaptability to Manufacturing Processes

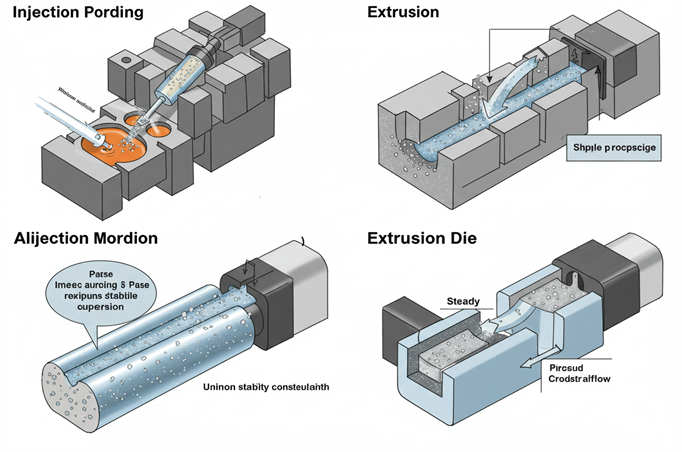

- Injection Molding: Use aluminum paste suitable for injection molding processes, such as non-spray aluminum silver strips, which maintain stability and do not melt or discolor at high temperatures.

- Extrusion Processing: To ensure the product’s appearance and performance, consider aluminum paste with good water permeability and dispersion properties.

5. Environmental Regulations

- Low Odor: Choose low-odor or odorless aluminum paste to comply with environmental regulations and worker health requirements.

- No Solvent Residue: Use solvent-free or low-solvent aluminum paste to ensure no harmful solvent residue is left in the finished product, maintaining product integrity and compliance with environmental standards.

6. Cost Considerations

- Цена: Choose aluminum paste with a good cost-performance ratio based on market positioning and budget.

- Dosage: High coverage and good water permeability aluminum paste can reduce the required dosage, saving costs.

Considering these factors, you can select the appropriate aluminum paste for plastics, meeting performance, and aesthetic requirements while fulfilling environmental and cost management needs.

Differences Between Oil-Based Aluminum Paste and Non-Spray Aluminum Silver Strips

Oil-based aluminum paste and non-spray aluminum silver strips have the following key differences:

1. Form and Composition

- Oil-based Aluminum Paste: The paste form primarily comprises aluminum powder, solvents, and additives.

- Non-Spray Aluminum Silver Strips: These are strip-form products composed of aluminum powder, additives, and media (such as wax), with an aluminum content of around 80%- 85%.

2. Environmental Performance

- Oil-based Aluminum Paste: Contains solvents, has a strong odor, and lower environmental performance.

- Non-Spray Aluminum Silver Strips: Solvent-free, odorless, and environmentally friendly.

3. Manufacturing Process Adaptability

- Oil-based Aluminum Paste: Suitable for oil-based system coatings and inks, requires processing such as grinding and mixing, and dispersion is relatively difficult.

- Non-Spray Aluminum Silver Strips: Used directly in plastic injection molding and masterbatch industries, added to plastic materials or powders during mixing and pelletizing, making it convenient to use.

4. Functional Characteristics

- Oil-based Aluminum Paste: Offers strong coverage and metallic sheen but has weaker dispersion stability.

- Non-Spray Aluminum Silver Strips: Provides good water permeability, compatibility, and stability, resulting in a uniform metallic effect.

5. Application Range

- Oil-based Aluminum Paste: Widely used in automotive paints, motorcycle paints, bicycle paints, plastic coatings, industrial paints, and inks.

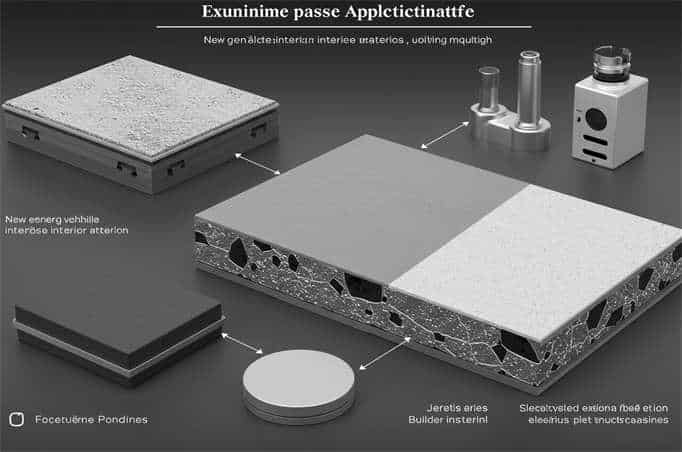

- Non-Spray Aluminum Silver Strips: These are used mainly in the plastic injection molding and masterbatch industries, for example, appliance casings, automotive interior and exterior parts, plastic bags, toys, mobile phone cases, and plastic profiles.

6. Cost

- Oil-based Aluminum Paste: Relatively lower price, suitable for cost-sensitive low-end products.

- Non-Spray Aluminum Silver Strips: Relatively higher price but improves efficiency and product quality.

Trends in Aluminum Paste Selection for Plastic Decoration

1. Emphasis on Environmental Performance

- Rise of Water-Based Aluminum Paste: With increasingly stringent environmental regulations, water-based aluminum paste has gained market favor due to its superior environmental performance. It reduces organic solvents and volatile organic compound emissions, aligning with sustainability goals. For example, in the plastic decoration industry, the water-based aluminum paste is ideal for producing eco-friendly plastic coatings and inks for home decor, toys, and more, ensuring aesthetics and compliance with environmental standards.

- Development of Solvent-Free Aluminum Paste: Solvent-free aluminum paste is becoming increasingly popular in addition to water-based aluminum paste. Solvent-free aluminum paste avoids organic solvents, reducing the risk of solvent evaporation and associated environmental and health hazards. It offers higher stability and environmental benefits, making it suitable for producing eco-friendly plastic films, sheets, and packaging materials.

2. Advancing Technological Innovation

- Particle Size Control: To meet the varying needs for gloss and coverage, aluminum paste’s particle size control system has rapidly developed, enhancing product uniformity and water permeability. In plastic decoration, precise control of aluminum paste particle size results in better metallic effects and decorative properties. For example, when producing plastic automotive interior components, using aluminum paste with uniform particle size and good water permeability creates finer, more consistent metallic textures that enhance product quality and appearance.

- Nanomaterials Development: The development of nanomaterials presents new opportunities for the aluminum paste industry. Nano aluminum paste offers high optical performance and unique physical properties, which can open new markets in high-end electronics, optics, and other fields. In plastic decoration, nano aluminum paste is ideal for producing plastic products with special optical effects, such as color-changing or rainbow effects, catering to consumer demands for personalized and fashionable products.

- Improvement of Surface Treatment Technologies: By improving surface treatment technologies for aluminum paste, its aging resistance, corrosion resistance, and UV protection can be enhanced. Этот ensures that plastic products retain their metallic appearance and decorative finish, even when exposed to harsh environments such as sunlight and rain, extending product lifespan.

3. Increased Demand for Personalization and Customization

- Demand for Unique Optical Effects: As consumer demand for aesthetic and personalized products rises, there is an increasing need for aluminum paste that delivers unique optical effects. For example, some plastic decorations must exhibit unique metallic textures, sparkling effects, or color-changing properties. By investing in research and innovation, aluminum paste manufacturers offer products with different optical effects, such as high-gloss, sparkling, and color-changing aluminum pastes, providing more options for the plastic decoration industry.

- Unique Functional Demands: Besides optical effects, the plastic decoration industry is seeing a growing need for aluminum paste with specialized functions. Some plastic decorations must possess antibacterial, anti-mold, or anti-static properties to meet specific application scenarios and hygiene requirements. By incorporating functional additives or conducting unique surface treatments, aluminum paste manufacturers have developed products with these properties, offering more solutions to the plastic decoration sector.

4. Expanding Applications

- New Energy Vehicle Interior Materials: With the rapid development of new energy vehicles, there are higher demands for the environmental performance and aesthetics of automotive interior materials. Aluminum paste is an essential decorative material used to produce dashboards, door panels, seats, and other components for new energy vehicles. It provides a metallic feel and enhances the aesthetic appeal. Additionally, the lightweight nature of aluminum paste helps reduce the vehicle’s weight, improving the driving range of new energy vehicles.

- Building Materials: In the building decoration industry, aluminum paste is used to produce plastic joint panels, plastic wall panels, plastic doors, and plastic windows, providing a metallic texture and aesthetic appearance. Moreover, aluminum paste’s aging and corrosion resistance help improve the longevity and reduce maintenance costs of building materials.

- Electronics and Electrical Products Casings: In the electronics and electrical industries, aluminum paste is used to manufacture casings for products like TVs, computers, and mobile phones. It provides a metallic finish and aesthetic effect. Aluminum paste’s conductivity and heat dissipation properties also improve electronic product performance and stability.

5. Implementing Smart Production

- Automation Equipment Usage: Aluminum paste manufacturers are adopting automatic grinding machines, mixers, and filling machines to improve production efficiency and product quality. In plastic decoration, aluminum paste made with automated equipment ensures product stability and consistency, meeting the requirements for mass production.

- Use of Information Systems: Aluminum paste manufacturers are integrating production management systems, quality control systems, and inventory management systems to intelligently manage and control the production process. In the plastic decoration industry, these systems improve efficiency, management levels, and cost control, helping optimize inventory costs.

Selecting the right aluminum paste for plastic decoration involves carefully considering various factors, including the type of paste, its performance characteristics, compatibility with the plastic substrate, adaptability to processing techniques, environmental requirements, and cost considerations. Oil-based aluminum paste and solvent-free aluminum silver strips offer distinct advantages and are suited for different applications. The industry is shifting towards more environmentally friendly options, such as water-based and solvent-free aluminum pastes, driven by technological innovations and the growing demand for personalized and functional products. By staying informed about these trends and making informed choices, you can enhance the quality and appeal of your plastic decorative products while meeting environmental and cost objectives.