Добро пожаловать в Fiver Star New Materials! We are a dedicated supplier of high-quality aluminum paste for the Autoclaved Lightweight Concrete (ALC) industry. Pursuing sustainable and efficient materials in the construction sector has never been more critical. ALC stands out as a cutting-edge building solution that offers a perfect blend of lightweight design, exceptional strength, and superior thermal insulation.

At Fiver Star New Materials, we understand that the production of high-performance ALC relies on the right mix of raw materials and advanced processes. Our aluminum paste plays a pivotal role in creating ALC, acting as a vital component that enhances the material’s properties. In this blog, we will explore the fascinating world of ALC, from its production to its applications, and delve into how our aluminum paste contributes to its outstanding characteristics. Join us as we uncover the potential of ALC and our products’ essential role in shaping sustainable construction’s future.

At Five Star New Materials, we supply high-performance aluminum paste, a crucial ingredient that empowers the production of Autoclaved Lightweight Concrete (ALC). ALC stands as a revolutionary building material, shaping the future of construction with its exceptional properties. We are proud to provide the essential component that helps make ALC possible.

Understanding Autoclaved Lightweight Concrete (ALC)

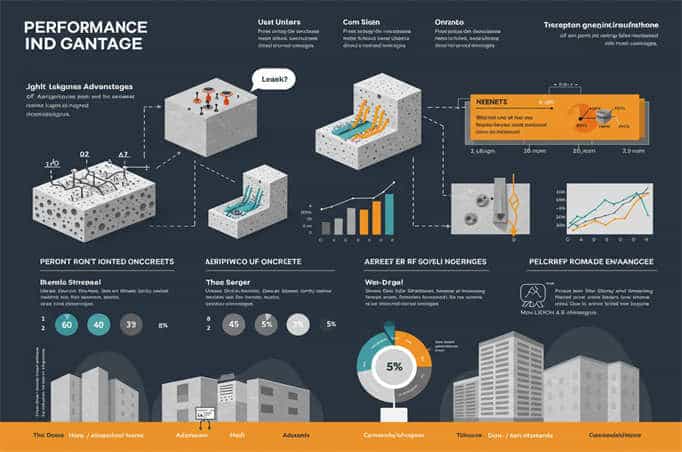

Manufacturers produce Autoclaved Lightweight Concrete by combining carefully selected raw materials, including fly ash (or silica sand), cement, and lime. Crucially, they incorporate our aluminum paste as the vital aeration agent.

The production process involves proportioning these materials, mixing, pouring, pre-curing, cutting, and finally, autoclaving (steam-curing under pressure). This sophisticated process yields a unique concrete product.

ALC is a porous concrete panel characterized by numerous delicate, evenly distributed pores. Our aluminum paste reacts with alkaline components in the mix during production to generate hydrogen gas. This reaction creates these essential pores, achieving a 60-70% porosity. This controlled structure is the key to ALC’s outstanding performance characteristics.

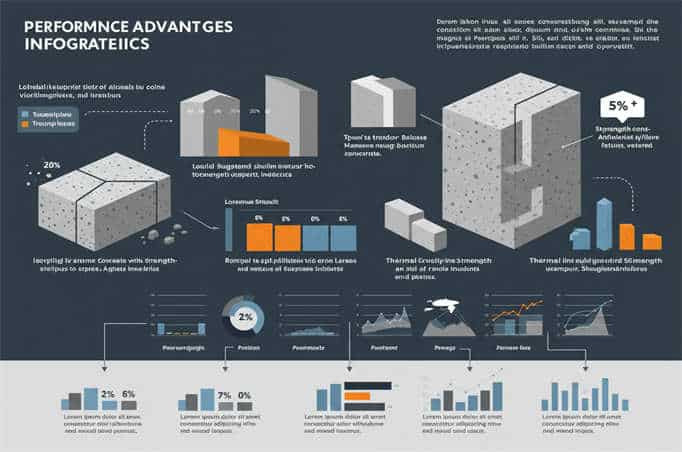

The Advantages Enabled by High-Quality Aeration

The porous structure, facilitated by our aluminum paste, gives Autoclaved Lightweight Concrete its remarkable properties:

Lightweight and High Strength

ALC achieves impressive strength despite its low density. For example, Grade 05 ALC panels typically have a density of around 525 kg/m³ yet offer a compressive strength of ≥4 MPa. This density is approximately one-quarter that of traditional concrete and one-third that of clay bricks. Этот significantly reduces a building’s dead load, leading to savings in foundation and structural costs.

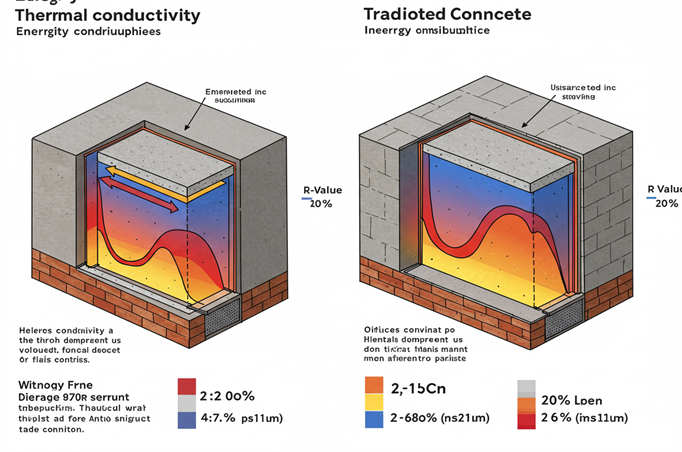

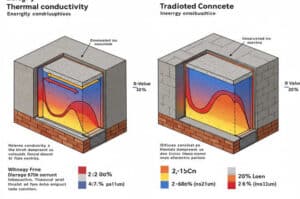

Superior Thermal Insulation

The entrapped air pores minimize thermal conductivity. Grade 05 ALC typically exhibits a thermal conductivity of ≤0.14 W/(m·K). Этот provides insulation performance far superior to traditional materials – approximately six times better than glass, three times better than clay brick, and ten times better than standard concrete. Этот enhances indoor comfort and significantly reduces building energy consumption for heating and cooling.

Отличная огнестойкость

As an inorganic material, ALC does not burn. Critically, it does not release harmful gases when exposed to high temperatures. Autoclaved Lightweight Concrete wall panels can achieve fire resistance ratings exceeding 4 hours, making them ideal for firewalls and escape routes.

Effective Sound Absorption and Insulation

The porous nature effectively absorbs sound waves. Depending on the thickness and density, ALC panels can reduce noise transmission by 30-50 decibels, contributing to quieter and more comfortable indoor environments.

Enhanced Seismic Performance

The material’s porous structure effectively absorbs and disperses seismic energy. Using ALC improves building safety and reliability, particularly in earthquake-prone regions.

Efficient and Clean Construction

Manufacturers can prefabricate ALC panels to precise dimensions in a factory setting. Workers can easily cut, drill, mill, and nail the panels on site. This accelerates the construction schedule, reduces wet trades on site, and contributes to a cleaner, more environmentally friendly building process.

Eco-Friendly Material

ALC production generates minimal pollution and does not release harmful substances. Manufacturers can utilize industrial byproducts like fly ash as a primary raw material, aligning with green building principles and sustainability goals.

Common ALC Panel Dimensions and Applications

ALC panels offer versatility for various construction needs:

- Длина: Typically customized based on floor height, available up to 6 meters.

- Width: Common widths include 600mm and 1200mm.

- Thickness: A wide range is available, such as 100mm, 150mm, and 200mm, selected based on design requirements.

Builders utilize Autoclaved Lightweight Concrete extensively for:

- Exterior Walls: Provides thermal insulation, durability, and reduced weight for residential, commercial, and industrial buildings.

- Interior Walls: Offers excellent sound insulation and fire resistance for partitions, simplifying construction and maximizing usable space.

- Floors: Suitable for floor systems in low-rise residential buildings, providing good acoustic and fire performance while reducing structural load.

- Roofs: Serves as structural decking and insulation layers, offering weather resistance and thermal efficiency.

- Fire Protection: Used for firewalls, shaft enclosures, and protection for steel structures due to its high fire rating.

- Decorative Elements: These can be surface-treated as an attractive and durable façade or interior finish.

The Five Star Advantage: Premium Aluminum Paste for ALC

Our aluminum paste is specifically engineered for the Autoclaved Lightweight Concrete industry. It performs critical functions:

- Precise Aeration: Our paste reacts predictably and efficiently with alkaline materials in the ALC mix, releasing hydrogen gas at a controlled rate. Этот creates the essential lightweight, uniformly porous structure.

- Enhancing Performance: The consistent, fine pores generated by Five Star’s aluminum paste directly contribute to ALC’s superior thermal insulation, sound absorption, and fire resistance properties.

- Optimizing Material Properties: By facilitating a controlled pore structure, our aluminum paste helps ALC manufacturers reliably achieve the target balance between low density and high compressive strength.

Why Particle Size Distribution Matters

At Five Star New Materials, we meticulously control the particle size and distribution of our aluminum paste because it directly impacts the final Autoclaved Lightweight Concrete quality:

- Optical Properties (Internal Structure): While less critical for ALC than coatings, finer particles offer a larger surface area for reaction. A narrow, consistent particle size distribution ensures uniform pore formation, leading to predictable density, strength, and thermal performance in the final ALC product. Uneven distribution can lead to variations in pore size and structure.

- Processing Performance: Filling & Density: A well-controlled particle distribution helps ensure the aeration process is uniform throughout the mix, contributing to a homogenous final product density and structure.

- Durability Link: A uniform pore structure, initiated by consistent aluminum particles, contributes to the ALC’s overall integrity and long-term durability.

- Application Performance:Dispersion: Our aluminum paste disperses easily and evenly within the ALC slurry. A narrow distribution minimizes settling variations, preventing inconsistencies and ensuring the stability and homogeneity of the mix before curing.

- Reactivity Control: Optimized particle size allows for predictable and manageable reaction rates during the gas generation phase, which is crucial for controlling the rise and initial set of the ALC mixture.

Best Practices for ALC Construction

To maximize the benefits of Autoclaved Lightweight Concrete enabled by our quality aluminum paste, contractors should observe proper handling and installation techniques:

- Moisture Protection: While ALC possesses some moisture resistance, designers must specify appropriate waterproofing membranes or coatings in areas prone to prolonged dampness or water exposure, such as bathrooms and kitchens.

- Installation Accuracy: Ensure panels are installed level and plumb. Precise installation, especially for exterior walls, affects the building’s appearance, watertightness, and overall safety. Seal joints meticulously according to manufacturer recommendations to prevent air or water leakage.

- Secure Anchoring: Follow structural engineering designs and relevant codes meticulously when anchoring ALC panels to the primary building structure. Proper anchoring guarantees stability, especially in multi-story buildings or areas with high seismic activity.

- Impact Prevention: Although ALC is robust, avoid subjecting panels to sharp impacts or heavy point loads during construction and occupancy. If damage occurs, repair or replace the affected sections promptly to maintain the integrity and performance of the element.

Partner with Five Star New Materials

Five Star New Materials provides a high-quality, reliable aluminum paste for producing superior Autoclaved Lightweight Concrete. Our commitment to quality control, particularly in particle size and distribution, ensures that ALC manufacturers can consistently produce top-tier building materials.

Choose Five Star New Materials as your aluminum paste supplier. Let us help you leverage the advanced properties of Autoclaved Lightweight Concrete to build a more efficient, sustainable, and resilient future.

Autoclaved Lightweight Concrete (ALC) is transforming the construction industry with its remarkable combination of lightweight, high-strength, and energy-efficient properties.

Throughout this blog, we have highlighted the key aspects of ALC production, its diverse applications, and the critical role of aluminum paste in enhancing its performance. As a trusted supplier of aluminum paste to the ALC industry, Fiver Star New Materials is committed to providing high-quality raw materials that help manufacturers produce high-quality ALC.

Our aluminum paste is carefully crafted to meet the specific needs of ALC production, ensuring optimal foaming, insulation, and strength. We are proud to support the construction industry’s shift towards sustainable practices by offering products that contribute to creating greener, more efficient buildings. Thank you for joining us on this journey to discover the potential of ALC and the importance of our aluminum paste.

We look forward to continuing to serve as a reliable partner in the growth of the ALC sector.