You want your solar panels to work their best, so picking the right aluminum paste is important. New studies say non-leafing aluminum paste is better for today’s solar panels because it sticks better and lasts longer. Leafing aluminum paste makes the surface shinier and more reflective, but it does not last as long. The table below shows how leafing and non-leafing pastes are different in reflectivity, adhesion, and durability:

| Недвижимость | Алюминиевая паста для литья | Алюминиевая паста, не вызывающая нареканий |

|---|---|---|

| Отражение | Shiny, metallic surface | Less shiny, more even |

| Adhesion | Weaker, gathers on surface | Stronger, spreads evenly |

| Долговечность | Less stable, shorter life | More stable, longer life |

The Solar Reflective Aluminum Paste you pick can affect how well your panels work and how long they last.

Основные выводы

- Non-leafing aluminum paste sticks better and lasts longer. This makes it good for new solar panels. – Leafing aluminum paste looks shiny but does not stick as well. It may not last as long because it can peel off. – Think about your weather and where your panels are before you pick a paste. – Leafing paste reflects more light and keeps panels cool. Non-leafing paste helps stop rust and damage. – Always try a small amount first. This helps you see if the paste works for you.

Виды алюминиевой пасты

Leafing Aluminum Paste Overview

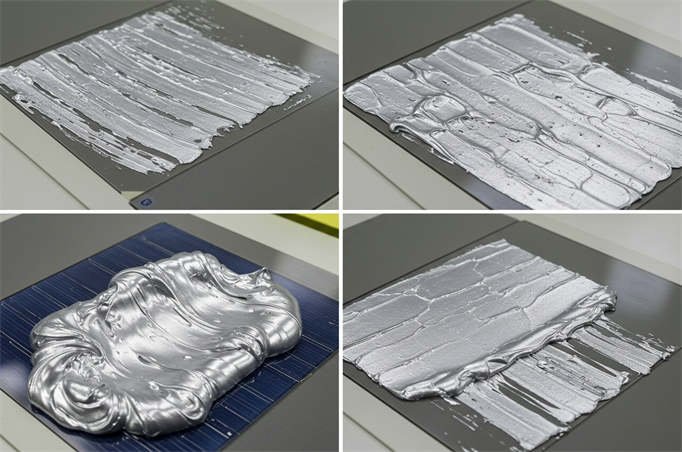

Leafing aluminum paste makes things look shiny and metallic. People make this paste by grinding aluminum powder into thin pieces. They add stearic acid to the flakes. This helps the flakes float to the top of the coating. When you use leafing aluminum paste, the flakes sit on the surface. This layer bounces sunlight away very well. You see this paste in products where shine and reflectivity are important.

Совет: Leafing aluminum paste can help surfaces stay cooler. This is good for solar panels that need less heat.

- High reflectivity coatings bounce solar radiation away.

- These coatings help solar panels stay cooler.

Non-Leafing Aluminum Paste Overview

Non-leafing aluminum paste works in a different way. The flakes mix evenly in the coating and do not float up. This gives a more even look that is not as shiny. Non-leafing pastes stick to surfaces better. They last longer, even in sunlight and bad weather. Many solar panel makers pick non-leafing aluminum paste. It protects panels and helps them work well for a long time.

| Недвижимость | Алюминиевая паста, не вызывающая нареканий | Алюминиевая паста для литья |

|---|---|---|

| Adhesion | Superior adhesion because flakes mix evenly | Poor adhesion since flakes float to the top |

| Long-term Durability | Lasts longer, handles damage, easy to keep up | Gets weaker over time, flakes can fall off |

Key Structural Differences

The biggest difference is how the flakes act in the coating. In leafing pastes, flakes move to the top and make a shiny shield. In non-leafing pastes, flakes spread out and stick better. This makes them last longer. If you want a Solar Reflective Aluminum Paste that shines more, pick leafing types. If you want your panels to last longer, non-leafing types are better.

- Non-leafing aluminum pastes stick better and last longer, so they are great for solar panels.

- Leafing aluminum pastes may stop rust at first but get weaker as flakes fall off.

Solar Reflective Aluminum Paste Performance

Reflectivity and Gloss

Solar panels work better when they reflect sunlight. Reflectivity and gloss are important for this. Leafing aluminum paste makes the surface look shiny like chrome. This happens because the flakes float to the top layer. The surface gets very reflective and bounces sunlight away. This helps keep panels cool and makes them work better.

The table below shows how the two pastes compare:

| Характеристика | Алюминиевая паста для литья | Алюминиевая паста, не вызывающая нареканий |

|---|---|---|

| Отражение | High, chrome-like finish | Moderate, uniform appearance |

Leafing aluminum paste makes the surface brighter. The flakes float up and form a mirror-like layer. This boosts how much light the panel reflects. If you want the most shine, leafing paste is best.

Non-leafing aluminum paste gives a more even look. The flakes mix in the coating and do not float up. The surface is less shiny but still reflects light well. For many panels, this is enough reflectivity.

Примечание: High reflectivity helps solar panels stay cooler and work better in hot weather.

Adhesion and Durability

Solar panels should last for years. Adhesion and durability are important when picking a Solar Reflective Aluminum Paste. Non-leafing aluminum paste sticks well to the panel. The flakes spread out and bond with the coating. This strong grip keeps the paste in place, even when the weather changes.

Leafing aluminum paste does not stick as well. The flakes float to the top and do not bond tightly. Over time, flakes can come loose. This weakens the coating and makes panels last less time.

- Non-leafing paste sticks better and protects longer.

- Leafing paste looks good at first but wears out faster.

If you want panels to handle rain, wind, and sun, non-leafing aluminum paste is better. The coating stays strong and works year after year.

Устойчивость к коррозии

Solar panels face tough weather. Rain, humidity, and pollution can cause rust. You need a Solar Reflective Aluminum Paste that protects panels from damage.

Non-leafing aluminum paste resists corrosion well. The flakes mix evenly and cover the surface. This layer blocks water and air and helps stop rust. Your panels stay safe and last longer.

Leafing aluminum paste protects against corrosion at first. The shiny top layer blocks moisture for a while. But flakes may fall off or move over time. This leaves gaps where water can get in and cause rust.

Совет: For long-lasting protection from rust, non-leafing aluminum paste is safer.

You want your solar panels to work well for many years. Picking the right Solar Reflective Aluminum Paste helps you get the best results, protection, and durability.

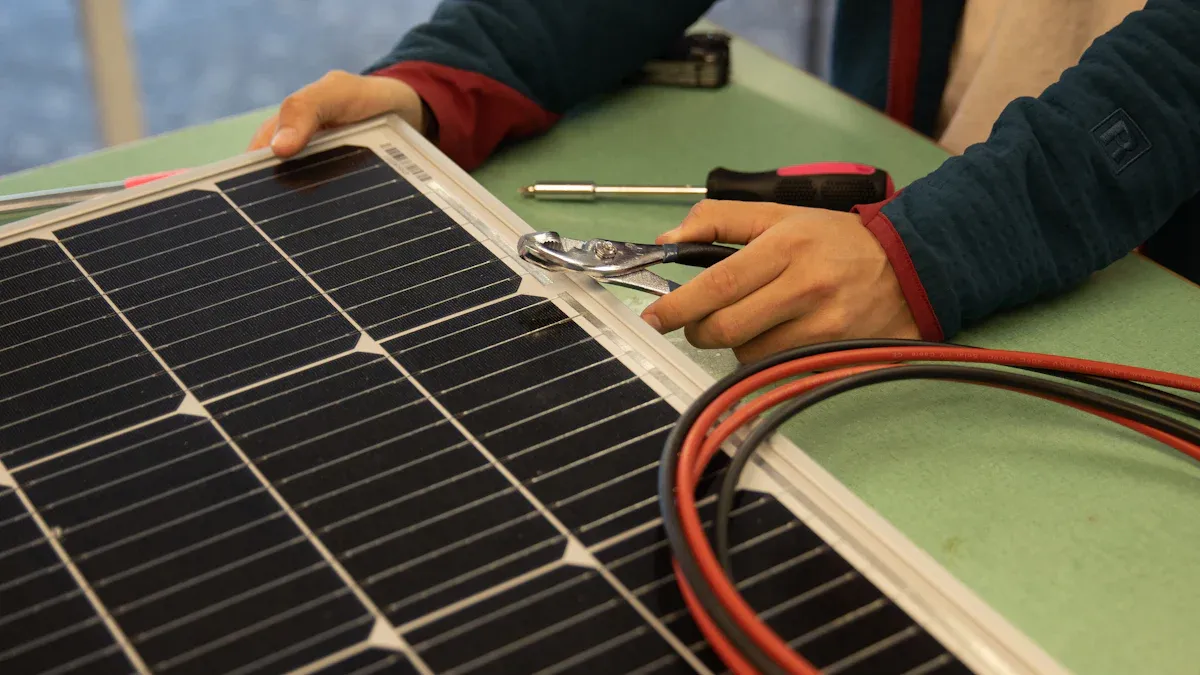

Application in Solar Panels

Leafing Paste Use Cases

You often see leafing aluminum paste in places where shine matters. This paste works well for solar panels that need high reflectivity. You might use it on panels that sit in very hot areas. The shiny surface helps bounce sunlight away. This keeps the panels cooler and helps them last longer. Some solar farms use leafing paste for panels on rooftops or open fields. These panels face strong sunlight every day.

- Leafing paste helps panels stay cool.

- You can use it for panels that need extra shine.

- It works best in dry climates with less rain.

Совет: Leafing paste gives a bright look, but you should check if your panels need more protection from weather.

Non-Leafing Paste Use Cases

Non-leafing aluminum paste fits panels that need to last a long time. You use this paste when you want strong protection. The flakes mix into the coating and stick well. This helps panels handle rain, wind, and dust. You often see non-leafing paste on panels in cities or places with harsh weather. It works well for panels on schools, factories, and homes.

- Non-leafing paste protects panels from rust.

- You can use it for panels in wet or windy places.

- It helps panels keep working year after year.

Примечание: Non-leafing paste gives less shine, but it makes panels stronger and safer.

Industry Examples

Many solar panel makers choose pastes based on their needs. For example, Five Star Aluminium Paste is a brand you might see in solar farms and factories. Some companies use leafing paste for panels in sunny deserts. Others pick non-leafing paste for panels in rainy cities. You can ask experts which paste fits your project. The right Solar Reflective Aluminum Paste helps your panels work better and last longer.

| Panel Location | Paste Type Used | Reason for Choice |

|---|---|---|

| Desert Solar Farm | Leafing | Высокая отражательная способность, cooler |

| City Rooftop | Non-Leafing | Strong protection, durable |

| School Installation | Non-Leafing | Long life, safe from rust |

If you want the best results, match the paste to your panel’s location and needs.

Choosing the Right Paste

Selection Factors

You need to look at several things before you pick an aluminum paste for your solar panels. The climate in your area matters. If you live where it rains a lot or gets very humid, you want a paste that fights rust. The type of solar panel also makes a difference. Some panels need more shine, while others need stronger protection. You should check how much sunlight your panels get each day. If your panels face strong sun, you may want a paste that keeps them cool.

Here are some key factors to consider:

- Weather conditions: Wet or dry climate

- Panel location: Rooftop, field, or city

- Desired reflectivity: High shine or even finish

- Durability needs: Short-term or long-term use

Совет: Ask your supplier about the paste’s test results for adhesion and corrosion resistance.

Matching Paste to Panel Design

You should match the paste to your panel’s design. Нанесение алюминиевой пасты works best for panels that need high reflectivity. These panels often sit in hot places and need to stay cool. Non-leafing aluminum paste fits panels that need to last a long time. These panels may face rain, wind, or dust. You can use a table to help you decide:

| Panel Type | Best Paste Choice | Reason |

|---|---|---|

| High-shine panels | Leafing | Maximum reflectivity |

| Durable panels | Non-Leafing | Strong protection |

| Urban panels | Non-Leafing | Rust resistance |

If you want your panels to last, pick a paste that matches your panel’s needs.

Common Mistakes

Many people make mistakes when choosing aluminum paste. You might pick a paste just because it looks shiny. This can lead to problems if the paste does not stick well. Some people forget to check the weather in their area. Others do not ask about the paste’s test results. You should avoid these mistakes:

- Choosing based only on appearance

- Ignoring climate and weather

- Not checking durability tests

- Using the same paste for every panel type

Примечание: You can avoid trouble by asking questions and reading product data sheets.

You now know that non-leafing aluminum paste works best for most modern solar panels because it lasts longer and protects better. Leafing paste gives more shine but does not last as long. When you choose a paste, focus on reflectivity, adhesion, and durability. For the best results, you should:

- Think about where you will use the panels and how you will apply the paste.

- Check for safety rules and cost.

- Test small samples before making a big decision.

Talking to technical experts helps you find the right match for your project.

Часто задаваемые вопросы

What is the main difference between leafing and non-leafing aluminum paste?

Leafing paste flakes move up and make things shiny. Non-leafing paste flakes stay mixed in the coating. This gives better protection and helps panels last longer.

Which aluminum paste should you use for panels in rainy areas?

Non-leafing aluminum paste is best for rainy places. It sticks tightly and keeps panels safe from rust and water.

Does leafing aluminum paste make solar panels more reflective?

Leafing aluminum paste makes the surface very shiny. This means the panels reflect more sunlight and stay cooler.

Can you mix leafing and non-leafing aluminum pastes?

You should not mix these two pastes together. Each type works best by itself. Mixing them can make your panels weaker and less safe.