Black aluminum powder, a specially treated aluminum powder with a black or dark gray appearance, is widely used in various industries due to its unique properties and versatile applications. This guide explores its characteristics, applications, and proper usage methods, providing valuable insights for professionals and enthusiasts.

Black aluminum powder, a specially treated aluminum powder with a black or dark gray appearance, is widely used in various industries due to its unique properties and versatile applications. This guide explores its characteristics, applications, and proper usage methods, providing valuable insights for professionals and enthusiasts.

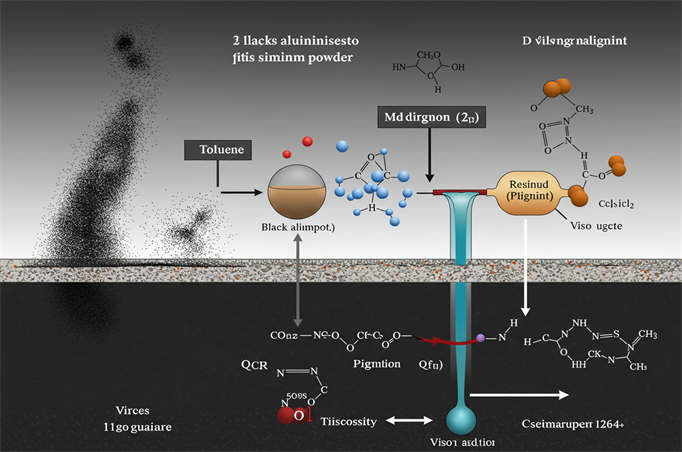

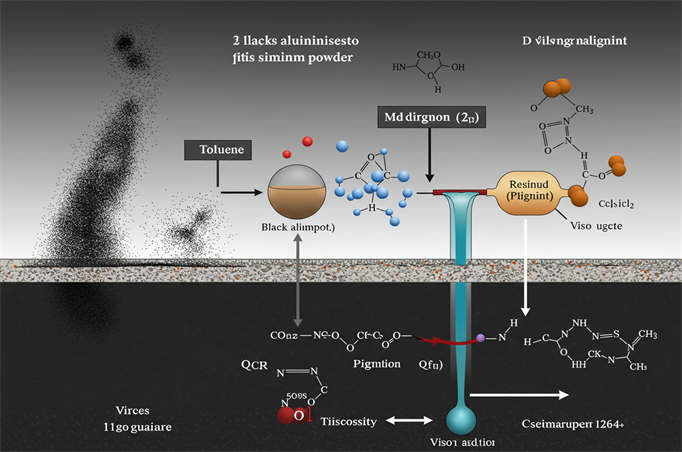

Black aluminum powder is a specially treated aluminum powder, typically covered with an aluminum oxide film on its surface. This oxide layer enhances the powder’s stability and antioxidant properties, giving it a black or grayish-black appearance.

In practical applications, black aluminum powder possesses unique characteristics and versatile uses. It is widely used across industries like coatings, inks, composite materials, aerospace, chemicals, metallurgy, refractory materials, anti-corrosion coatings, fireworks, and bamboo industries. For example, black aluminum powder is used in coatings to create metallic textured black paints, enhancing products’ aesthetic and protective properties. In composite materials, it is a reinforcing material to improve strength and wear resistance.

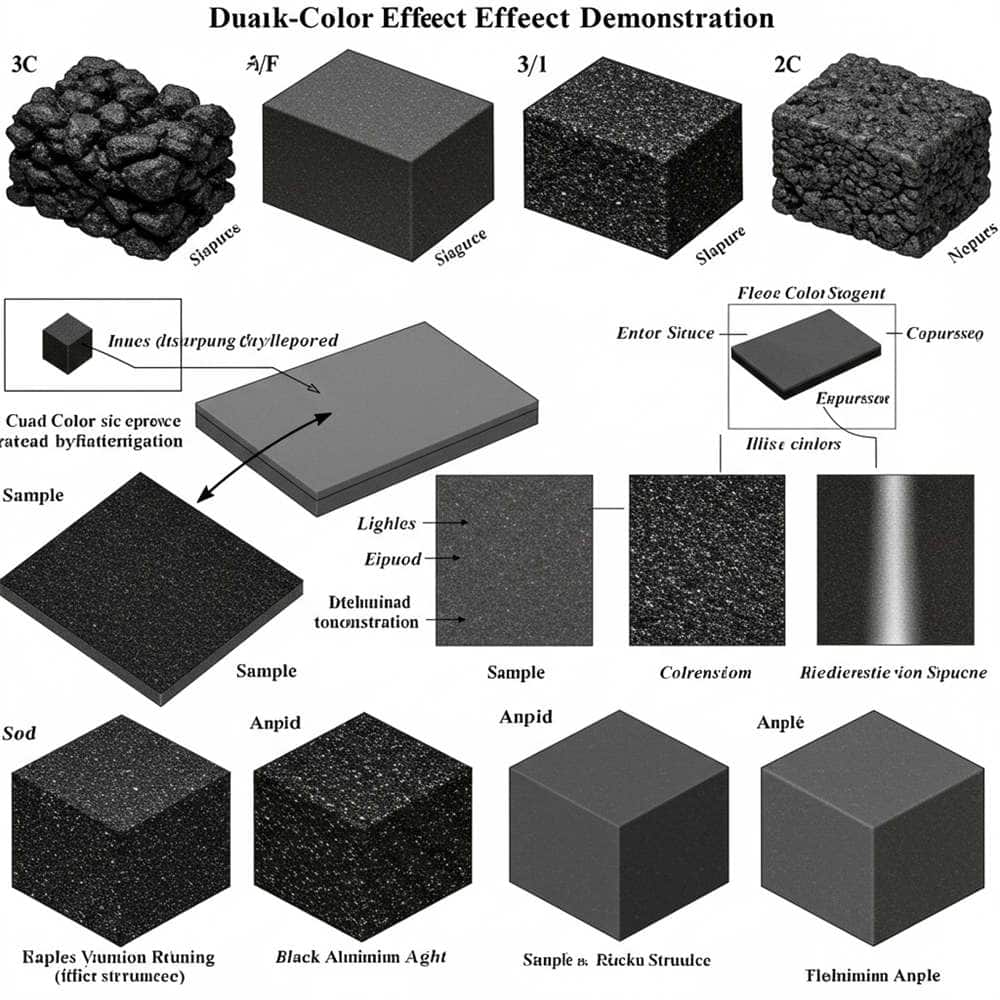

Additionally, black aluminum powder exhibits a “dual-color effect,” where its gloss and color depth change based on the incident angle and viewing angle when mixed with transparent pigments. This feature makes it especially valuable for special coatings and decorative materials.

It is important to note that specific safety and operational protocols must be followed when using black aluminum powder to ensure its flexible application and safe handling.

Black aluminum powder is commonly used in coatings. Below are some popular methods:

By following these methods, black aluminum powder can effectively be used in coatings, offering unique decorative and functional benefits.

To achieve the desired smoothness, the amount of aluminum powder should be adjusted based on the specific requirements and the coating system, typically ranging from 1% to 10%. Here are some guidelines:

By following this approach, you can effectively adjust the amount of aluminum powder to achieve the ideal smoothness.

The ideal amount of aluminum powder for achieving the desired gloss in coatings typically falls between 1% and 10%, depending on specific requirements and the coating system used. By understanding the relationship between aluminum powder usage and gloss and considering factors like particle size and dispersion, you can effectively adjust the Dosage to reach the optimal gloss for your coating projects.

Unlock Premium Performance with 5Star Materials’ Black Aluminum Powder

🌟 Key Takeaways at a Glance

| Property | Benefit | Ideal For |

|---|---|---|

| Enhanced Stability | Oxide layer ensures oxidation resistance & longevity | Aerospace, Automotive Coatings |

| Dual-Color Effect | Dynamic color shifts for eye-catching finishes | Decorative Materials, Luxury Goods |

| Superior Coverage | High hiding power reduces application layers | Industrial Paints, Anti-Corrosion |

| Customizable Smoothness | Adjust particle size (1-10% dosage) for matte to high-gloss finishes | Textured Coatings, Consumer Electronics |

| Multi-Industry Versatility | Compatible with water-based/solvent systems, composites, refractories | Construction, Marine, Energy |

Transform Your Coatings with Industrial-Grade Black Aluminum Powder At 5Star Materials; we specialize in delivering high-performance black aluminum powder engineered to elevate your products’ aesthetics, durability, and functionality. Whether you’re crafting metallic-textured paints, corrosion-resistant coatings, or cutting-edge composites, our premium-grade powder offers unmatched versatility and reliability.

✅ Precision Engineering: Our powder is treated to achieve uniform particle distribution, ensuring flawless dispersion in coatings and composites. ✅ Tailored Solutions: Adjust gloss, coverage, and color depth with customizable particle sizes (5-50µm) and dosages (1-10%). ✅ Industry-Proven Performance: Trusted by aerospace, automotive, and marine industries for UV resistance, thermal stability, and anti-corrosion properties. ✅ Safety First: Strict compliance with OSHA and ISO standards—safe handling guidelines included with every order.

🔥 Fast Turnarounds: Bulk orders shipped in 3-5 business days. 💡 Expert Support: Our technical team provides formulation guidance, troubleshooting, and SDS documentation. 🌍 Global Reach: Reliable delivery across the U.S., Europe, and Asia-Pacific.

📞 Contact Our Team Today! 👉 Request a Free Sample: Test our black aluminum powder in your formulations. Get Your Sample 👉 Download Technical Specs: Explore particle sizes, SDS, and application guides. View Resources 👉 Custom Quotes: Optimize costs with volume discounts. Get Pricing

Limited-Time Offer: Order 100+ kg and receive a complimentary dispersion optimization consultation!

5Star Materials – Where Innovation Meets Reliability. 🔗 Explore Products | 📧 sales@5starmaterials.com | 📞+86-18001668319

We suggest you to communicate with us fully before purchasing, we will certainly consider all aspects and provide a fair and reasonable price plan. By choosing us, you will get the best product and the best value for your money.

Choosing the right size of product gives you the best value for money. Our Metal Flash Aluminum Silver Paste is available in a wide range of particle sizes and purities, with prices varying by specification. By communicating your needs in detail and choosing the right size, you can get the best value for your money.

The larger the quantity purchased, the lower the unit price will be. Bulk orders allow us to better share our production and operating costs, so we are happy to offer discounted prices for bulk purchases.

The timing and method of payment you choose will also affect the price. For example, paying in full upfront can result in a more favourable price, as it reduces our cost of capital. Please discuss the most suitable payment option with our sales team.

Transport and logistics are also factors that affect the total cost of ownership. Different modes of transport and destinations will incur different shipping costs. Duties, insurance and other costs also need to be taken into account. By calculating these factors in advance of purchase, you can more accurately estimate the total cost.

At Five Star Material, we understand that every project is unique, and our goal is to provide the best customized solutions for each customer.

We will contact you within 24 hours.

For your urgent inquiries,please contact us through whatsapp No. : +86-13309617918